Ultrasonic flaw detection method for truck wheel axles and dedicated flaw detector

An ultrasonic and axle technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as loss, and achieve complete flaw detection and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

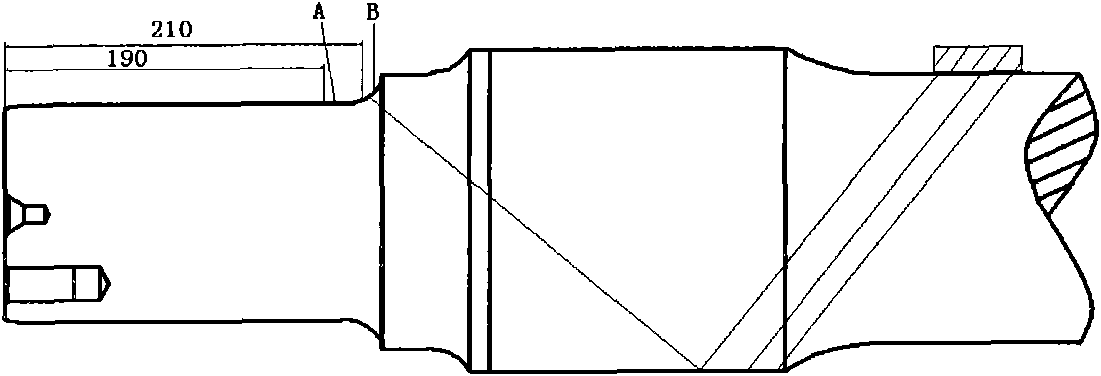

[0027] Physical axle test block:

[0028] Prepare one physical shaft for RD2 and RE2B, one artificial defect with wire cutting depth of 1mm and 0.5mm respectively at the root of the journal at both ends of the RD2 shaft at 200mm, 210mm, and 215mm from the shaft end, and one at the two ends of the RE2B shaft The root of the neck is 180mm, 200mm, and 205mm away from the shaft end, respectively, with a wire cutting depth of 1mm and 0.5mm for each artificial defect, and then a bearing is installed on one of the ends as a comparison artificial experimental shaft.

[0029] Scan mechanical system

[0030] A) Shaft end scanning system

[0031] Straight probe, 23.3-degree small-angle longitudinal wave probe (RD2), 27.3-degree small-angle longitudinal wave probe (RE2B) combined multi-probe scanning system is suitable for quick selection of different axial types. Encoder coding, as the basis for accurate positioning and comparison of B-scan. And through the adsorption of the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com