WNN planetary reduction gear with large transmission ratio

A technology of planetary deceleration and large transmission ratio, which is applied in transmission devices, gear transmission devices, belts/chains/gears, etc. It can solve the problems of difficult processing of eccentric shafts, low reduction ratios, complex structures, etc., and achieve processing difficulty The effect of small size, large carrying capacity and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

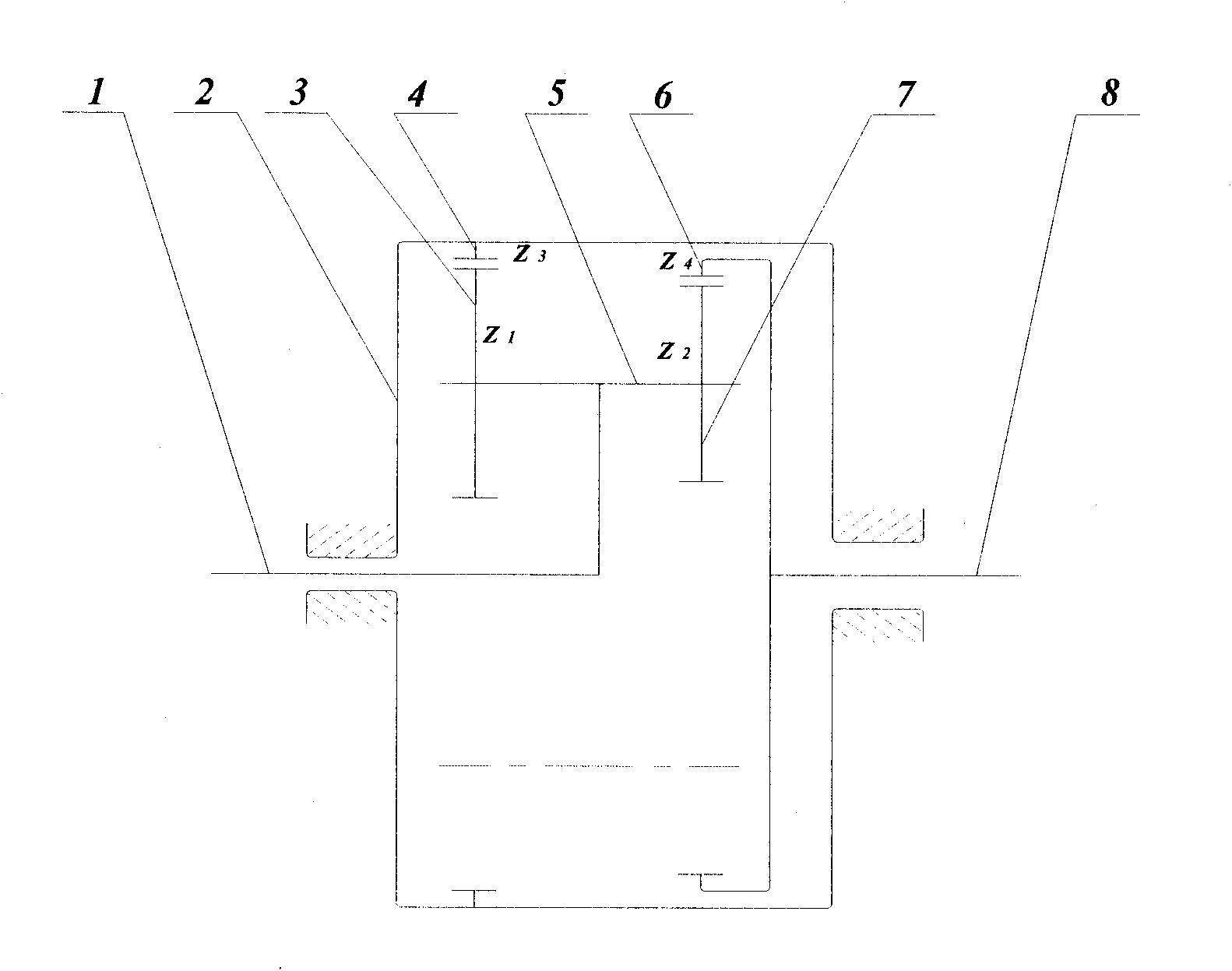

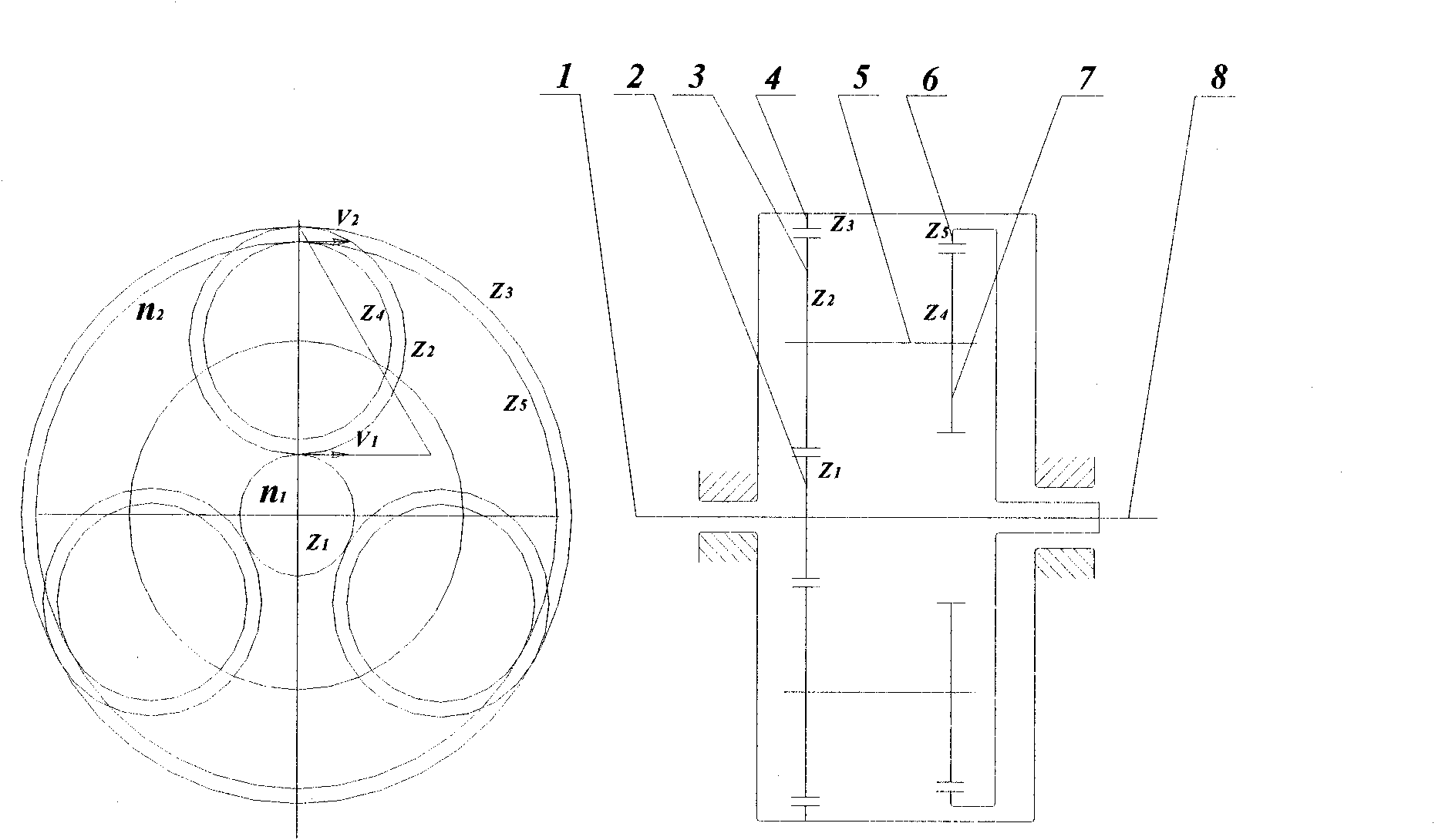

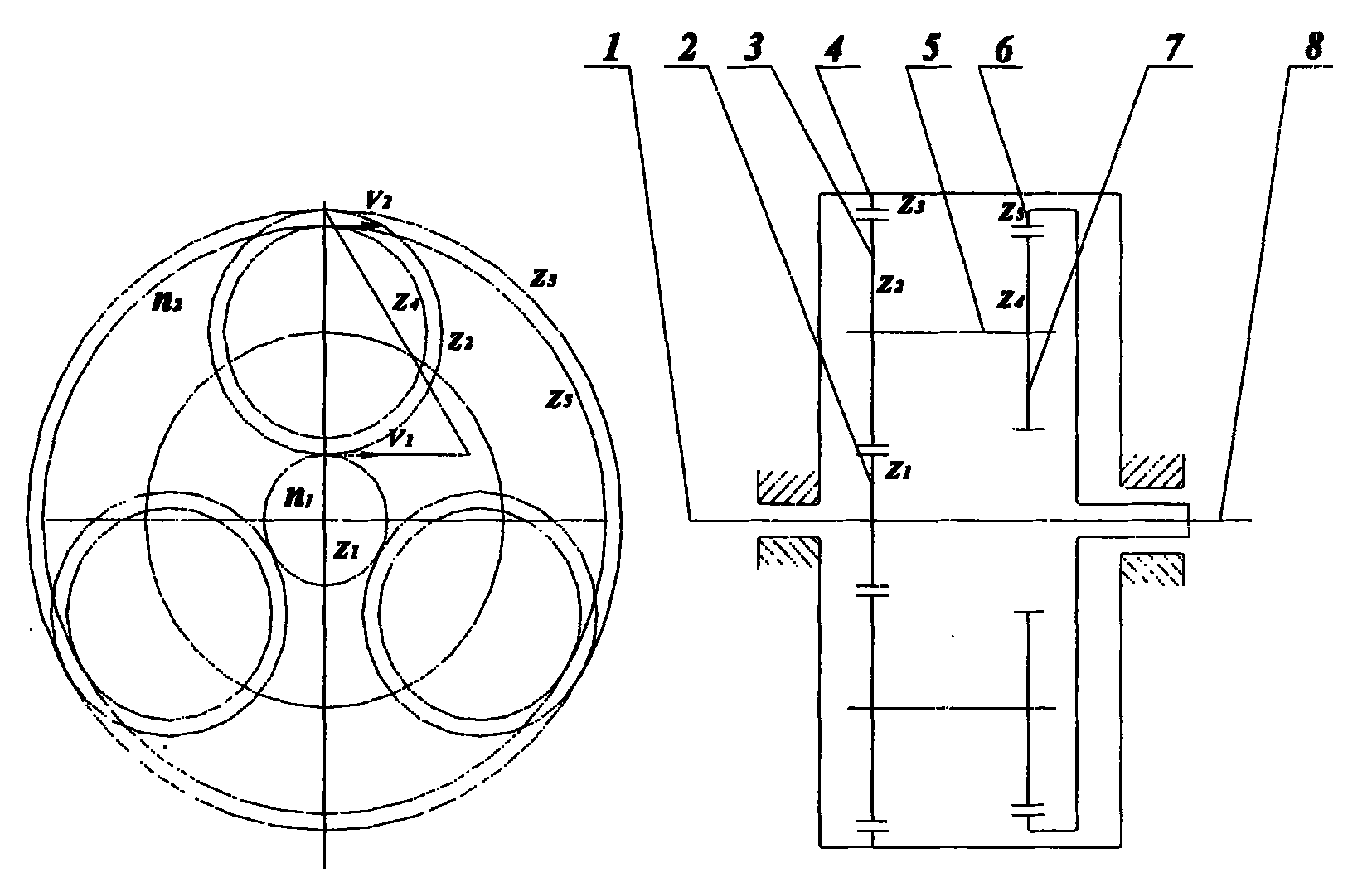

[0018] Example 1: Combining figure 2 , the present invention is a WNN planetary reduction device with large transmission ratio, which is composed of input shaft (1), gear Z1 (2), gear Z2 (3), gear Z3 (4), intermediate shaft (5), gear Z4 ( 7), gear Z5 (6) and output shaft (8), the input shaft (1) is connected to gear Z1 (2), gear Z1 (2) is connected to gear Z2 (3), and gear Z2 (3) is connected to the intermediate shaft ( 5), the intermediate shaft (5) is connected to the gear Z4 (7), the gear Z4 (7) is connected to the gear Z5 (6), and the gear Z5 (6) is connected to the output shaft (8).

Embodiment 2

[0019] Example 2: Combining figure 2 , a WNN planetary reduction device with a large transmission ratio of the present invention does not use an eccentric frame to drive the internal gear pair, but designs a pair of external transmission gear pairs Z1, Z2, and the central shaft of the gear Z2 (3) drives two internal gear pairs.

[0020] The transmission principle of the present invention: the motor drives the input shaft to rotate, the gear Z1 rotates accordingly, and the gear Z2 meshing with it rotates. Since the gear Z3 is fixed, the three gears Z2 are forced to revolve along the gear Z3 in addition to rotating around the central axis. , and the gear Z2 rotates, drives the coaxial gear Z4 to rotate, and drives the internal gear Z5 meshed with it to rotate, and the gear Z5 is integrated with the output shaft, and then drives the output shaft to rotate.

Embodiment 3

[0021] Example 3: Binding figure 2 , the present invention is a WNN planetary reduction device with a large transmission ratio, and the transmission ratio is calculated as follows: from figure 2 Velocity triangle relationship in , we get:

[0022] V2=V1×(Z2-Z4) / Z2

[0023] n1=V1 / Z1×π

[0024] n2=V2 / Z5×π

[0025] And Z5=Z1+Z2+Z4

[0026] Therefore, the transmission ratio i=n1 / n2=Z2×(Z1+Z2+Z4) / Z1×(Z2-Z4)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com