Tobacco curing room with hot air internal circulation

A technology of hot air flow and internal circulation, applied in the field of air-curing rooms, can solve the problems of changing air-curing style, increasing carbon emissions, imbalance between input and output, etc., achieving good thermal insulation effect, modulating environmental changes, and facilitating The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

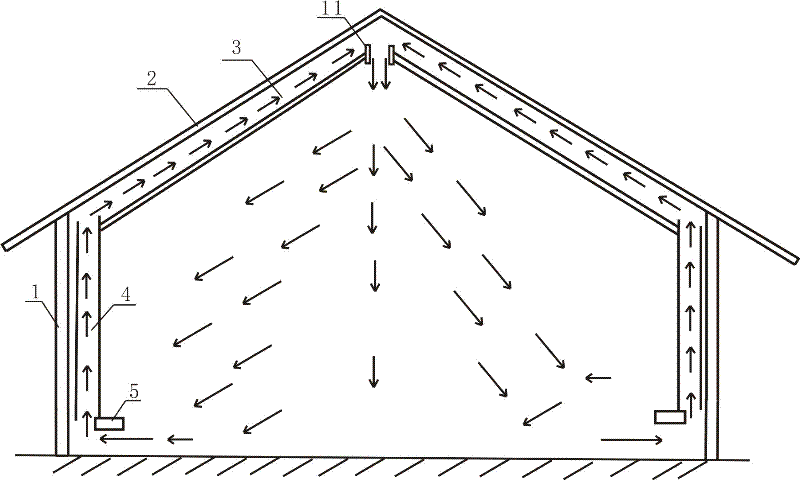

[0019] like figure 1 As shown, the present invention comprises a body of wall 1 and a ceiling 2 fixedly installed on the body of wall 1, and the interior of the ceiling 2 with the closed upper end is provided with a plurality of upper hot air flow ascending passages 3, and the upper end of the upper hot air ascending passage 3 is open, and the upper hot air flow The lower end of the ascending passage 3 communicates with the lower hot air ascending passage 4 arranged inside the wall body 1 , and the lower hot air ascending passage 4 is provided with an inlet switch valve 5 .

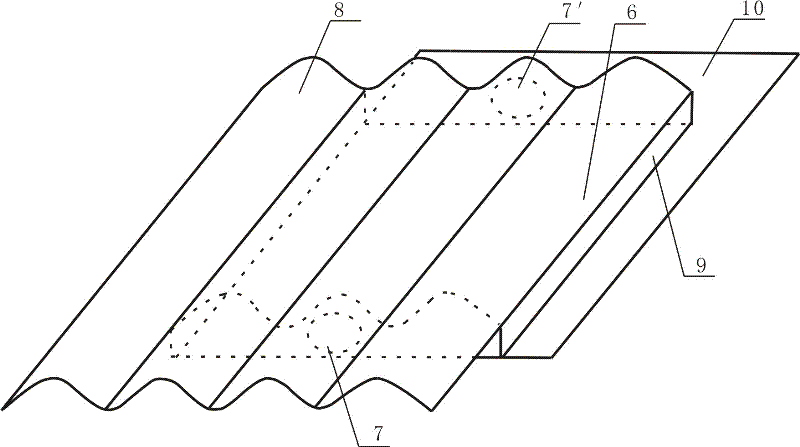

[0020] The ceiling 2 is composed of a plurality of double-layer heat-insulation blocks with a cavity heat-insulation layer 6, and the two sides of each double-layer heat-insulation block are provided with air vents 7, 7', and each double-layer heat-insulation block in the longitudinal direction of the ceiling 2 The cavity heat insulation layers 6 communicate with each other through vents 7 , 7 ′ to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com