Bobbin packager

A packaging machine and I-shaped wheel technology, which is applied in the direction of rotating and wrapping items, can solve the problems of low manual control ability and insufficient sealing effect of plastic wrap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

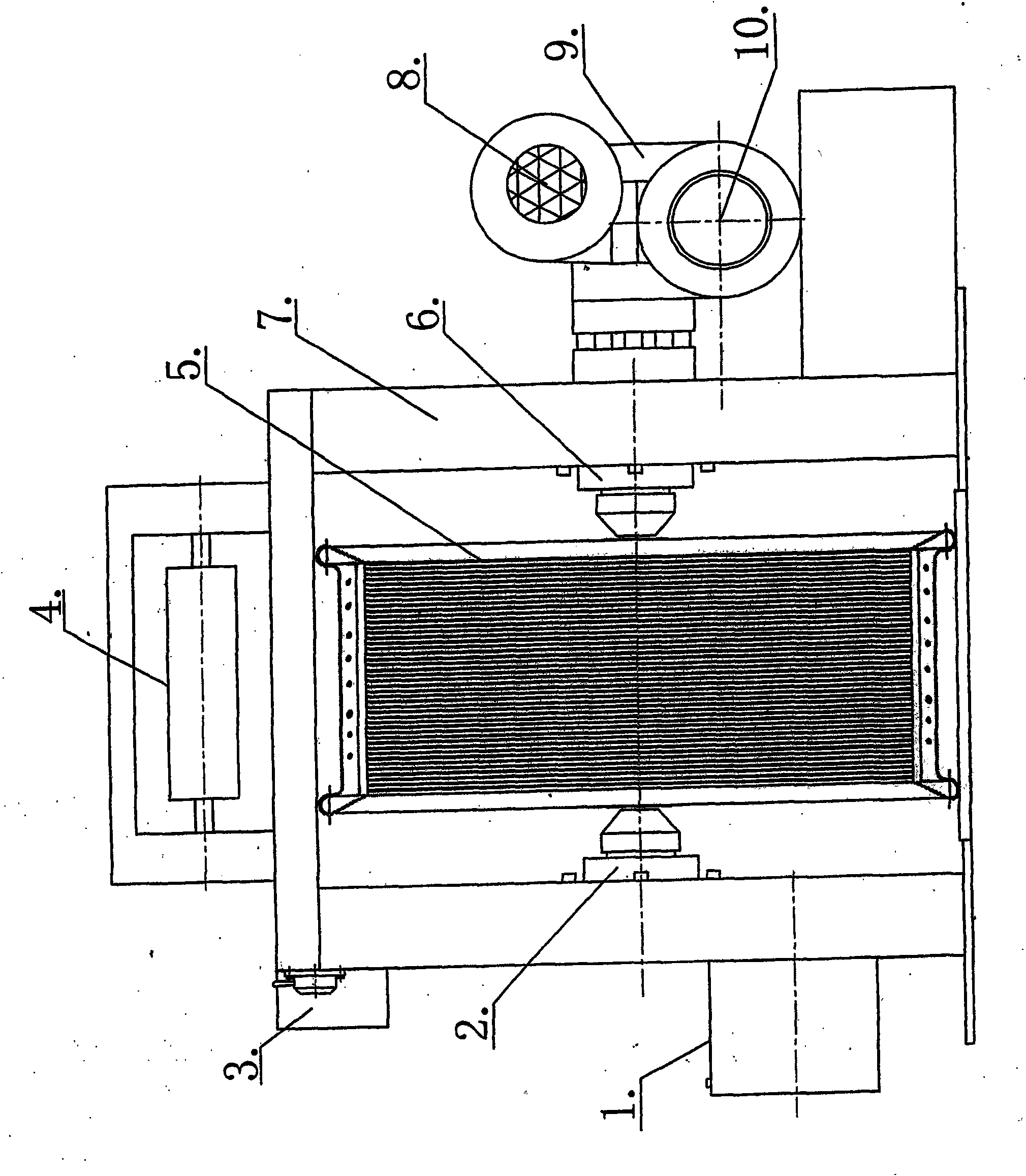

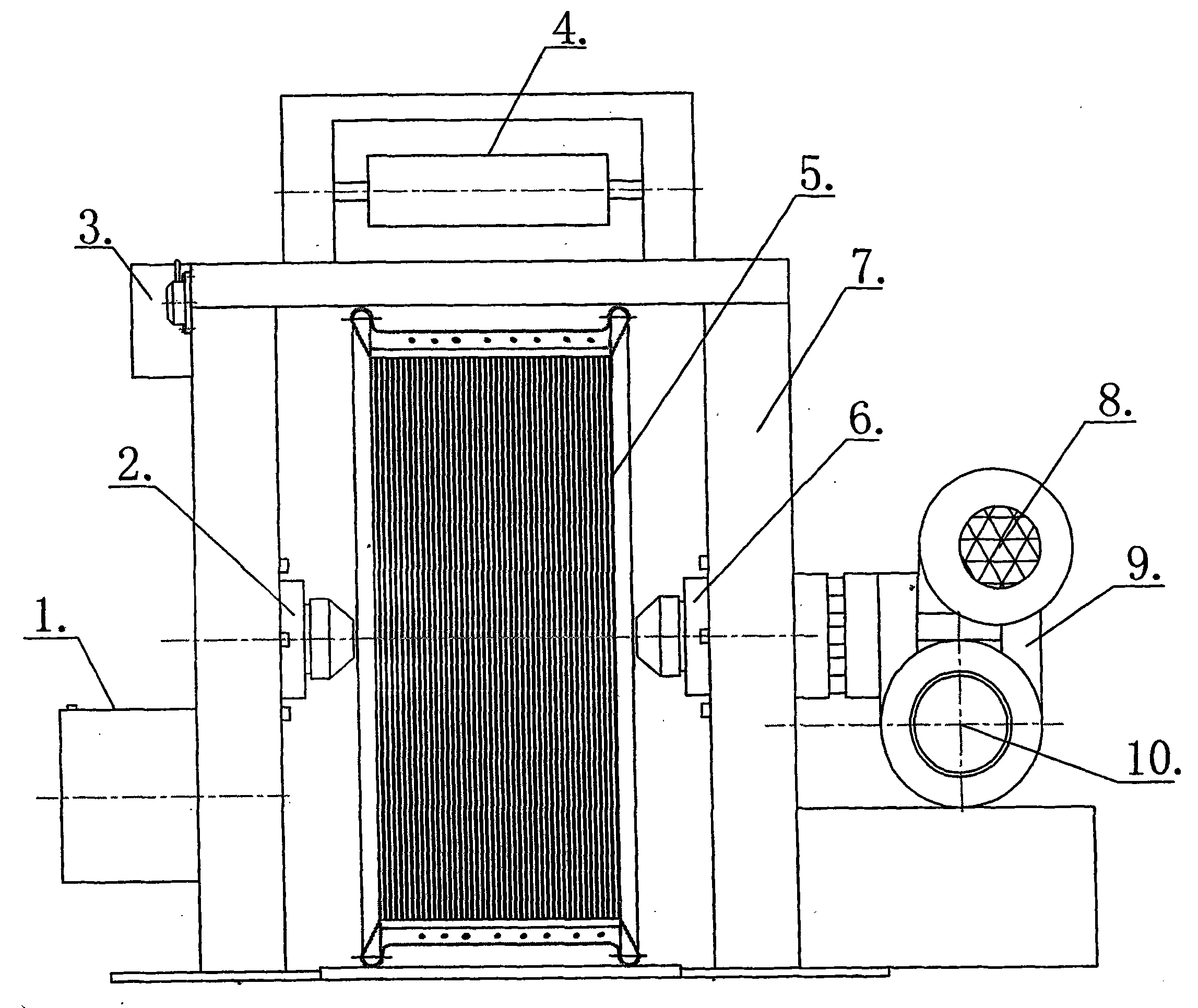

[0009] Such as figure 1 Shown, the present invention is provided with preservative film 4 at the top of frame 7, is provided with control box 3 at the top side of frame 7, is provided with cylinder 1 at the bottom end side of frame 7, clamps top 2 and The fixed tops 6 are arranged in the frame 7 respectively, the fixed tops 6 are connected with the speed reducer 9 , the speed reducer 9 is connected with the driving motor 10 , and a cooling fan 8 is also arranged at the top of the speed reducer 9 . During work, fix the I-shaped wheel 5 winding the finished steel wire on the frame 7 by clamping the top 2 and fixing the top 6, and then paste the beginning of the plastic wrap on the I-shaped wheel 5 with a sealing tape. After starting the packaging machine, The I-shaped wheel 5 rotates at a constant speed along with the rotation of the central shaft, and the preservative film 4 is just wound on the I-shaped wheel 5 voluntarily.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com