Electric trolley frequency conversion speed-regulating locomotive

A technology of variable frequency speed regulation and electric locomotive, applied in electric locomotives, locomotives, motor vehicles and other directions, can solve the problems of locomotive wheel lock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

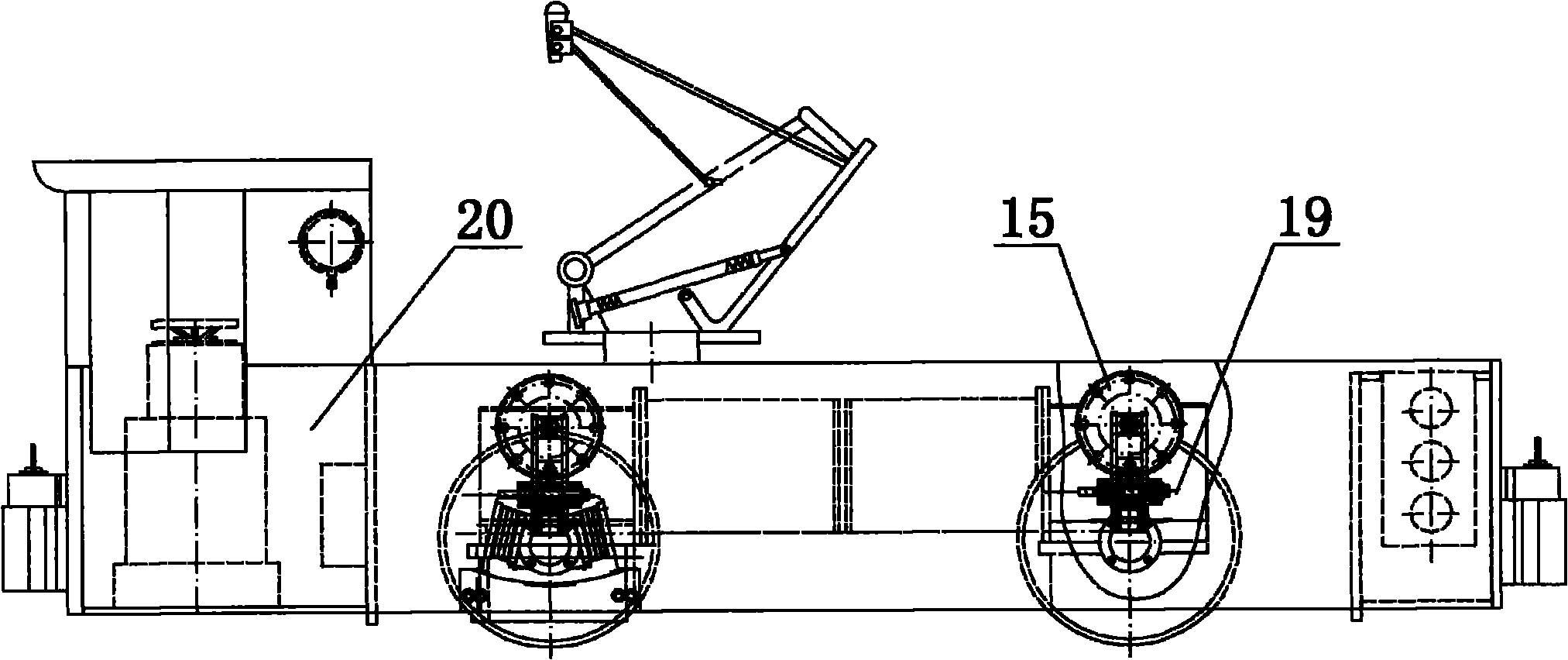

[0015] The present invention comprises vehicle frame assembly 13 and sand spreading device 17, and driver's cab assembly 20 is set at the front end of vehicle frame assembly 13, and vehicle frame assembly 13 is equipped with running device 14 and frequency conversion speed regulation electrical control system 18, and walking Anti-lock braking devices 15 are respectively installed on both sides of the device 14 . The anti-lock braking device 15 is a normally closed electromagnetic time-delay braking device, which is generally installed on the electric locomotive gearbox housing, and it is mainly composed of a brake disc spring 6, a cylinder body 7, a cylinder rod, Electromagnetic core 8, brake lever 4, caliper disc brake body 9, brake disc 2, electromagnetic pressure switch device 12 and wire-type electric locomotive power failure anti-braking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com