Positioning and clamping device and method for milling small-size flat long and thin parts

A milling processing and clamping device technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems that affect the total time of the processing process, reduce production efficiency, and increase labor intensity of workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

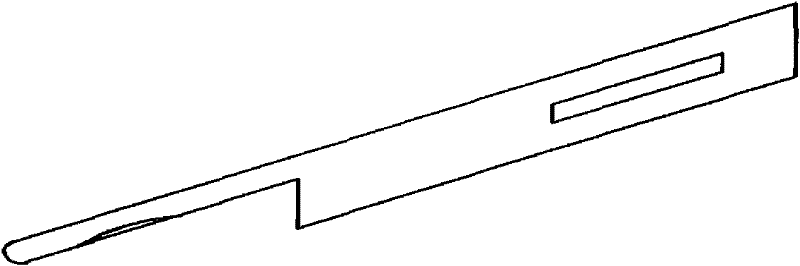

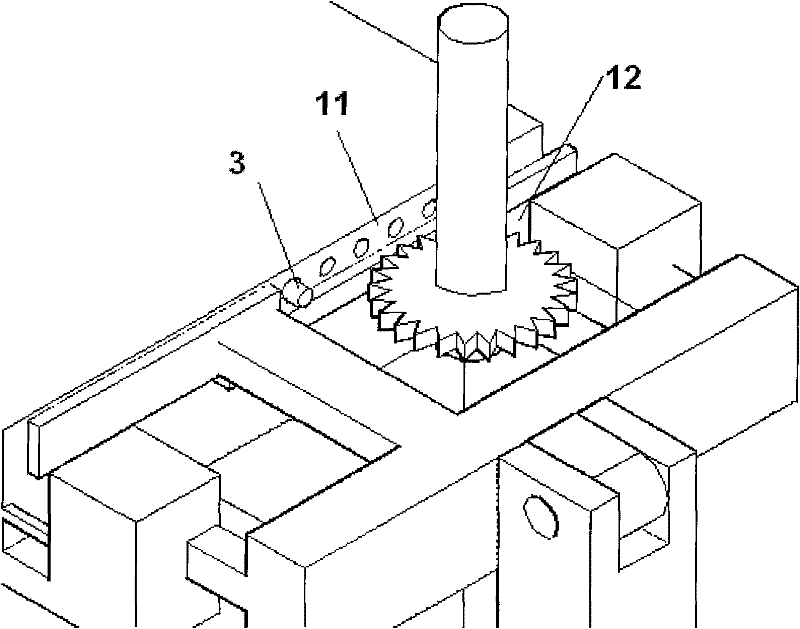

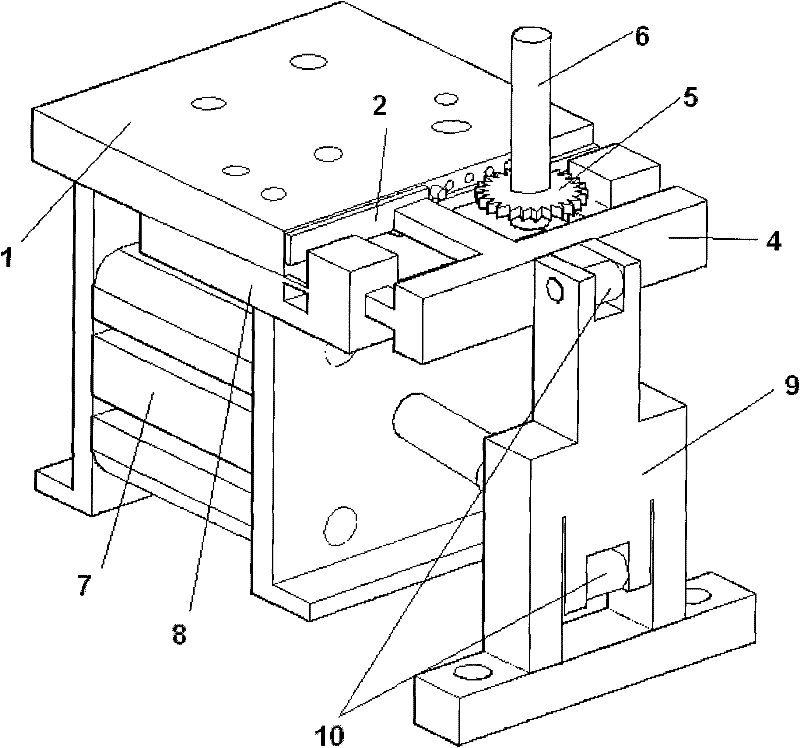

[0022] Such as figure 2 , image 3 As shown, a positioning and clamping device for milling of small flat and slender parts includes a clamp body 1, a clamping element 4, a guide element 8, a cylinder 7 and a transmission hinge 10, and the side of the clamp body 1 has a concave There are at least two positioning holes beside the groove, and the positioning holes are provided with a limit pin 3. The guide element 8 is connected to the bottom of the clamp body 1, and a guide groove is provided in the middle, and the clamping element 4 is connected to On the fixed frame 9, the fixed frame 9 is connected with the cylinder 7, and is located directly in front of the groove of the clip body 1.

[0023] The clamping element 4 has clamping arms facing the direction of the clamping body 1, and the clamping arms on the left and right sides are located in the guide grooves of the guide element 8, and the cylinder 7 is located below the guide element 8 and passes through the front telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com