Separating method of fly ash and device thereof

A separation device and fly ash technology, applied in the direction of solid separation, classification, chemical instruments and methods, etc., to achieve the effects of safety and wide application range, convenient installation and operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

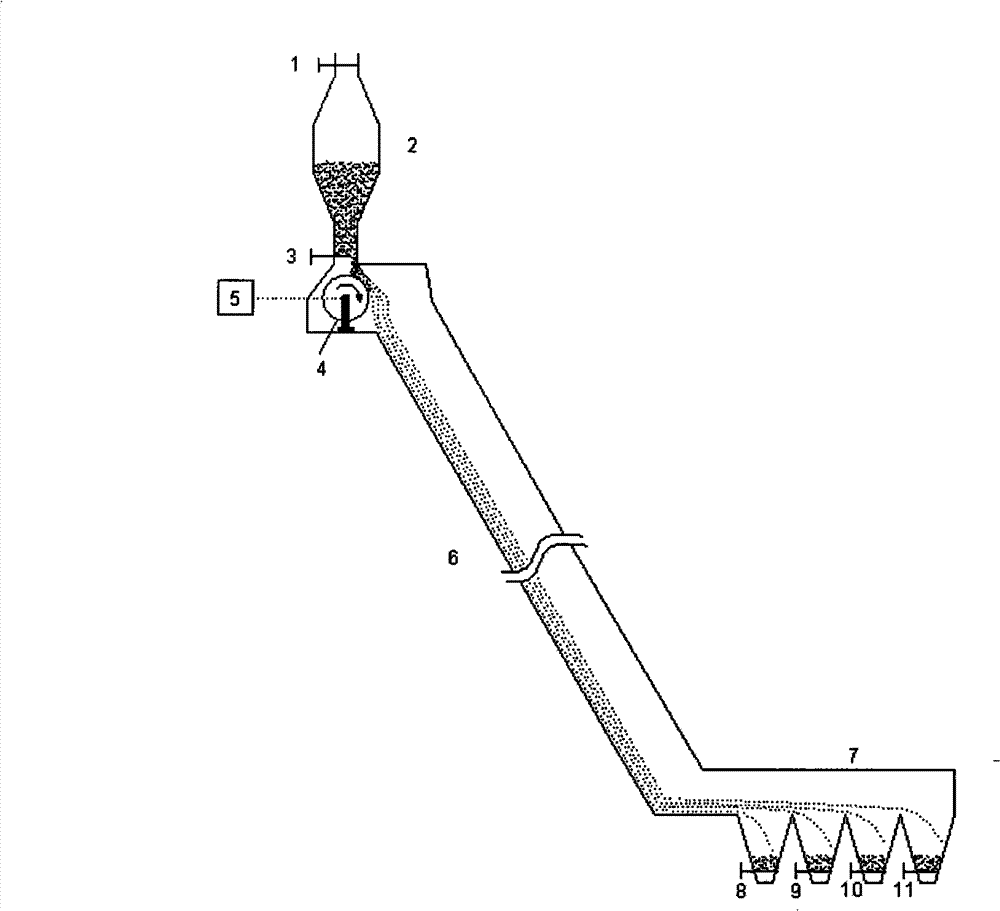

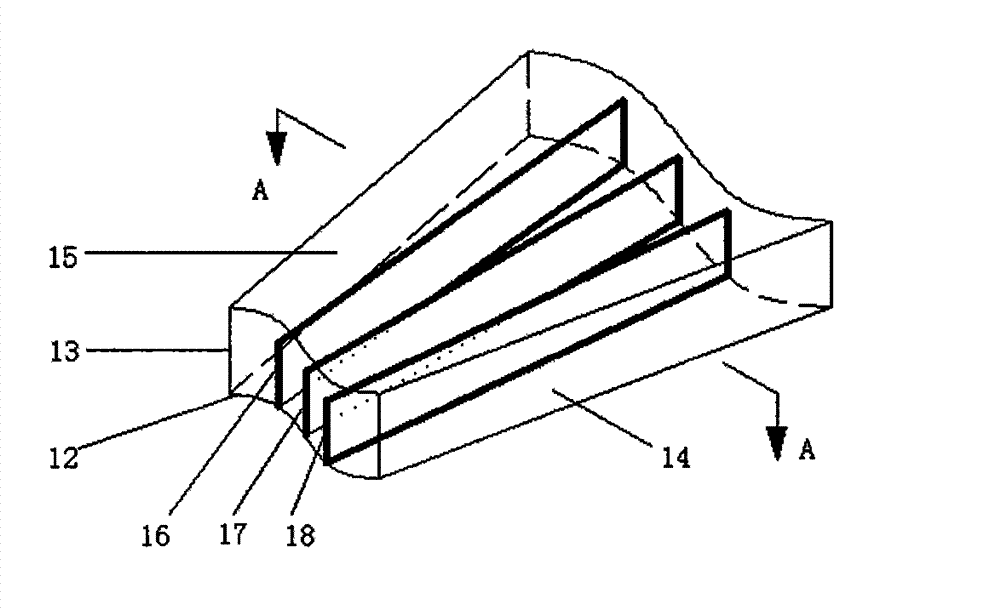

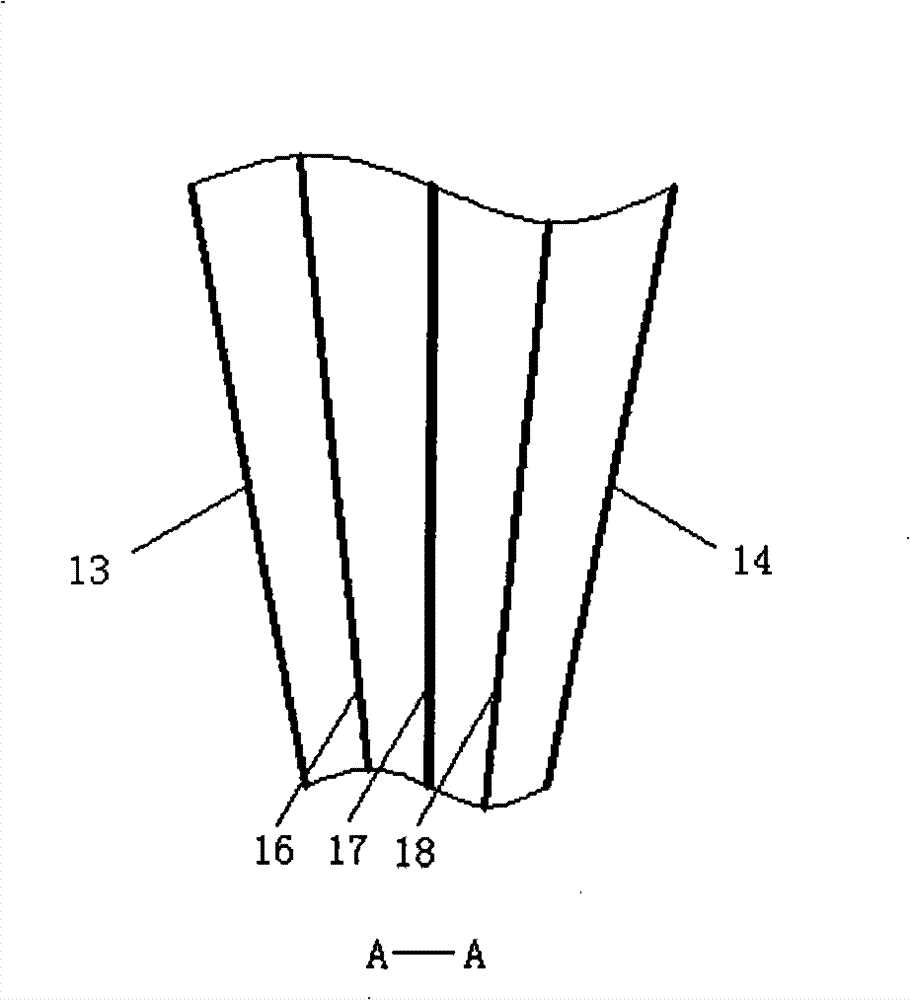

[0016] The fly ash separation method of the present invention uses gravity to make the thin layer of fly ash flow on the inclined surface of the chute with the horizontal section at the end, and the fly ash particles with different particle sizes, densities or surface shapes produce different After falling into the collection bin, there will be different drop points, that is, it will fall into different collection bins under the action of gravity, so as to realize the separation of fly ash particles. Specifically, the dry fly ash in the hopper falls to the surface of the rotating electric roller and then splashes onto the inclined bottom surface of the chute, and then flows in a thin layer on the inclined bottom surface under the action of gravity. There is a horizontal section on the bottom surface of the end of the chute , particles with different particle sizes, densities or shapes produce different outflow velocities at the end of the horizontal section, and finally fall in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com