Preparation and installation method of personalized orthodontic material and locating support

A technology of orthodontic materials and positioning brackets, applied in the direction of brackets, etc., can solve the problems of brackets, buccal tube slippage, incomplete fit for patients, and affecting the effect of orthodontic treatment, so as to reduce burden, shorten chair time, and position precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method for manufacturing and installing personalized orthodontic materials, the method comprising:

[0046] (1) Measure the point cloud data of the teeth to obtain the shape and structure parameters of the teeth; the point cloud data of the teeth can be directly scanned by CT tomography or a non-contact 3D scanner, or a plaster model of the patient's teeth can be made first and then processed 3D scanning;

[0047] (2) Establish a three-dimensional model of the tooth according to the point cloud data of the measured tooth; adopt a reverse engineering method to establish a three-dimensional CAD model of the tooth and store it in the computer;

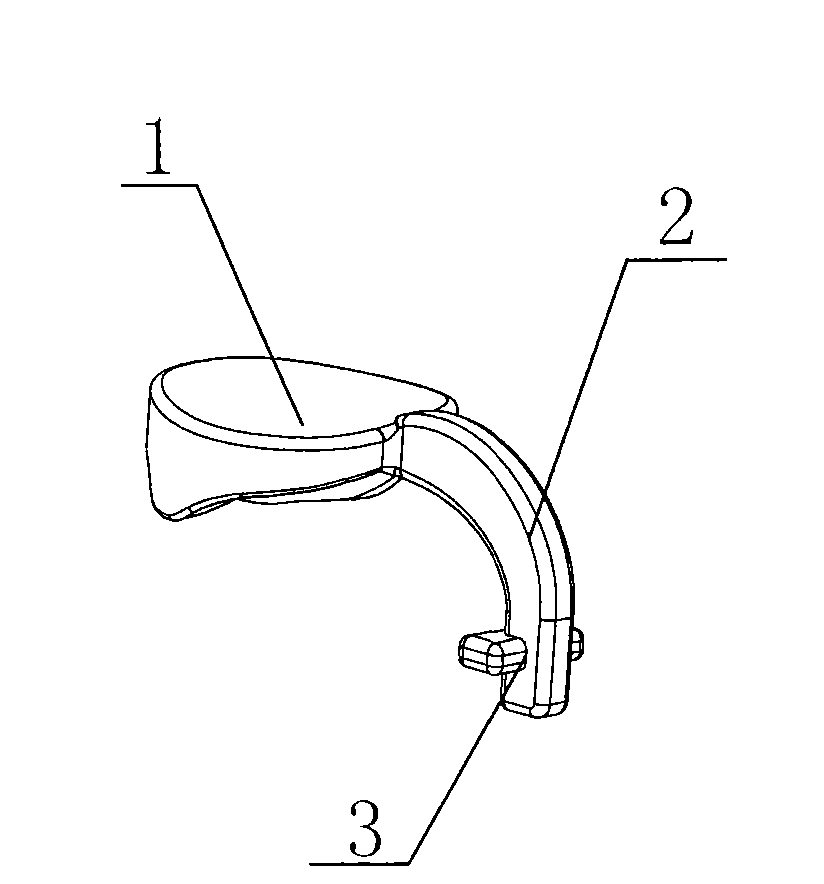

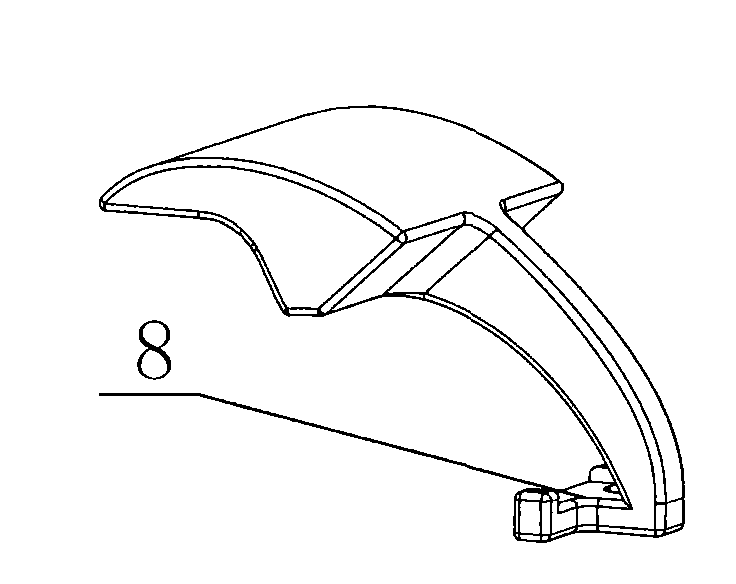

[0048] (3) Design personalized orthodontic materials according to orthodontic requirements, orthodontic material production materials and tooth shape characteristics; design the structural model of orthodontic materials, including designing brackets, buccal tubes and bottom plates in contact with tooth surfaces, And determine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com