Automatic seeder

A seeder, automatic technology, applied in the field of seeder, can solve the problems of slow seeding speed, uneven seeding, heavy workload, etc., and achieve the effect of smooth seeding action, uniform seeding, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

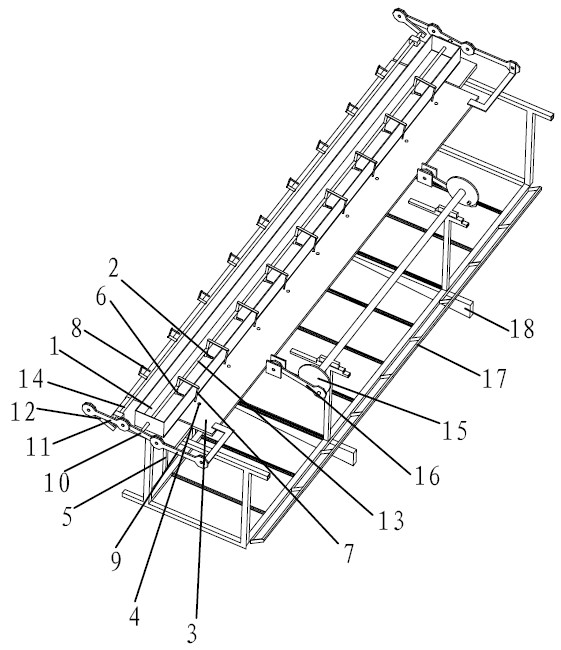

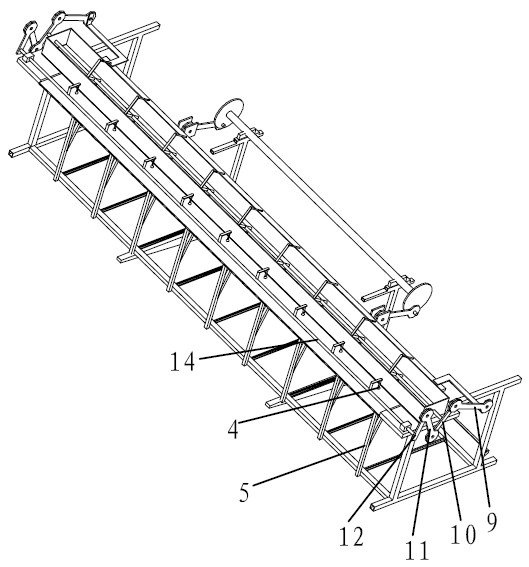

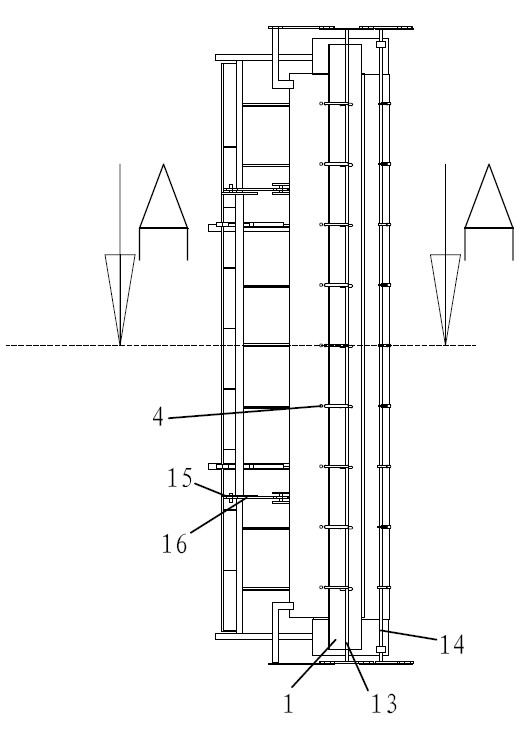

[0026] An automatic seeder such as figure 1 , 2 As shown, nine sets of sowing units are installed, and each sowing unit is provided with a seeding trough 1, and a feed port 2 is provided under the seeding trough 1, and the feed port 2 is long strip shape, and a seeding plate 3 is installed under the seeding trough 1, and the seeding plate 3 The front is hinged with a driving rod 16, and the other end of the driving rod 16 is hinged at the disc eccentric position of the driving wheel 15; Figure 4 As shown, the sowing plate 3 of each sowing unit is provided with two sowing holes 4, the bottom of the sowing plate 3 is provided with a baffle 19, the baffle 19 is provided with two through holes 20, and the bottom of the baffle 19 is provided with a The seed conduit 5, the seed conduit 5 is provided with two upper ports, respectively located directly below the two through holes 20; the drive wheel 15 converts the rotation into the reciprocating motion of the sowing plate 3 through...

Embodiment 2

[0030] The difference from Embodiment 1 is that a motor and a storage battery are installed in the bracket 17 of the automatic seeder, and the output shaft of the motor drives the driving wheel 15 to rotate.

Embodiment 3

[0032] The difference from Embodiment 1 is that the seeding trough 1 is funnel-shaped, and the automatic seeder includes six sets of seeding units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com