Plasma panel display adopting mixed protection layer and preparation method of mixed protection layer

A plasma display and protective layer technology, which is applied in the manufacture of tubes/lamp screens, solid cathode components, cold cathode tubes, etc. The effect of luminous efficiency and faster response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

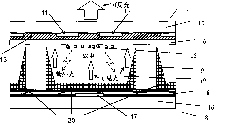

[0034] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

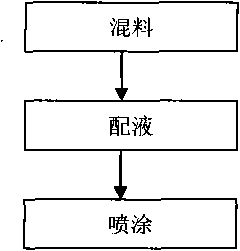

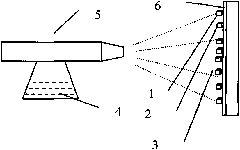

[0035] Such asfigure 1 , figure 2 Shown, a kind of preparation method of plasma display hybrid protective layer comprises the steps:

[0036] The first step: mixing materials: Mg containing 30% to 50% Zn 1-x Zn x O crystals are used as source 1, and Mg containing 0-10% Zn 1-x Zn x O crystal is used as source 2, the particle size of source 1 and source 2 is 200nm-2μm, and then source 1 accounting for 50-70% of the total weight and source 2 accounting for 30-50% of the total weight are mixed to form the source Three 3;

[0037] The second step: liquid preparation: the source three 3 mixed in the first step is dispersed in the volatile organic solvent according to the proportion of 5-10% of the solvent weight used, and it is uniformly dispersed in the solvent through ultrasonic treatment to obtain Spray solution 4;

[0038] The third step: spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com