Boiling dryer outputting material by using inert gas

A boiling dryer and inert gas technology, applied in the direction of drying solid materials, dryers, drying gas layout, etc., can solve problems such as large impact on quality, achieve good drying effect, improve boiling ability, and reduce material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: A kind of boiling dryer with argon as material output medium.

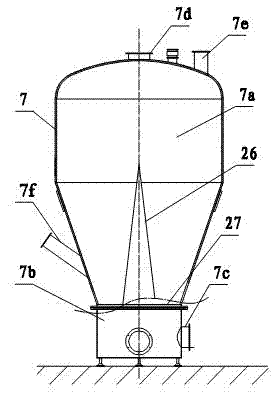

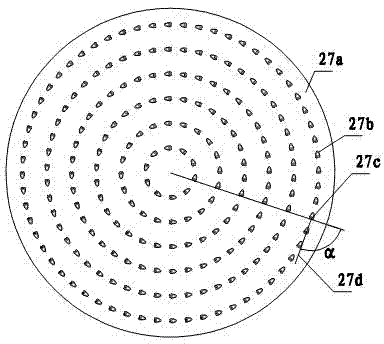

[0025] like figure 2 As shown, the air distribution plate 27 is horizontally arranged in the drying container 7, and the air distribution holes are evenly arranged on the air distribution plate 27. The air distribution plate 27 divides the drying container 7 into a drying chamber 7a and a hot air chamber 7b. The upper side of the air distribution plate 27 is a drying chamber 7a, the middle of the top of the drying chamber 7a is provided with an air outlet 7d, one side of the top of the drying chamber 7a is provided with a feed inlet 7e, and the top of the drying chamber 7a is also provided with a discharge port with a size smaller than the air outlet 7d. Air valve 28, discharge opening 7f is provided on the side wall of the bottom of drying chamber 7a, air inlet 7c is provided on the side wall of hot air chamber 7b, and rack platform 6 for easy operation is provided on the outside of drying con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com