Method for manufacturing novel wooden fireproof door leaf and door frame

A production method and a new technology, applied in fire doors, fireproof coatings, door leaves, etc., can solve the problems of not being able to play a fireproof role, and achieve the effects of excellent water resistance, simple operation, and high-strength fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

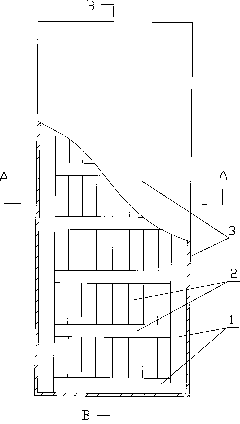

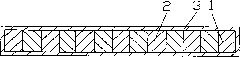

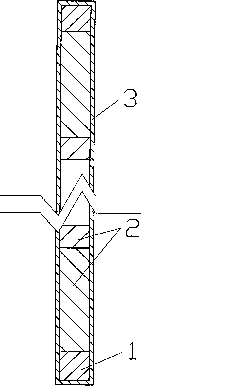

[0020] Such as Figure 1-6 Shown: a method for making a new wooden fireproof door leaf and door frame. The door leaf is composed of an overall frame 1 made of dry wood and a filler block 2 inside the frame. The door leaf filler block is mixed with waste wood into a new fireproof paint 3 is filled in the overall skeleton 1 (such as Figure 1-3 As shown), the surface of the door leaf is sprayed with new fireproof coating 3, and the thickness is 3-5mm. During production, the door leaf sprayed with new fireproof coating 3 on the surface is put into a press for rectification. After a few hours, the door leaf Natural curing molding; the door frame is made up of a horizontal frame 4 and a longitudinal frame 5 made of dry wood, and the outer periphery of the door frame is sprayed with a new fireproof coating 6 (such as Figure 4-6 shown), the thickness is 3-5mm.

[0021] The weight ratio and production process of each component in the new fireproof coating are as follows: 20-30 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com