Self reset curvature-prevention support component

An anti-buckling support and self-resetting technology, which is applied to building components, on-site preparation of building components, pillars, etc., can solve problems such as excessive residual deformation, increase post-earthquake maintenance, and dissipate earthquake energy to reduce residual deformation , avoid bolt loosening, and avoid the effect of friction surface aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

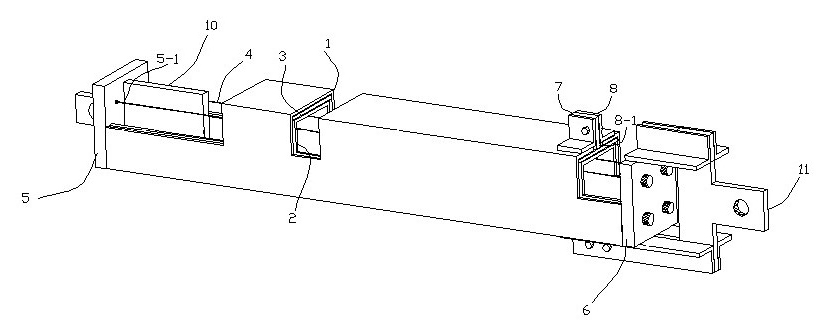

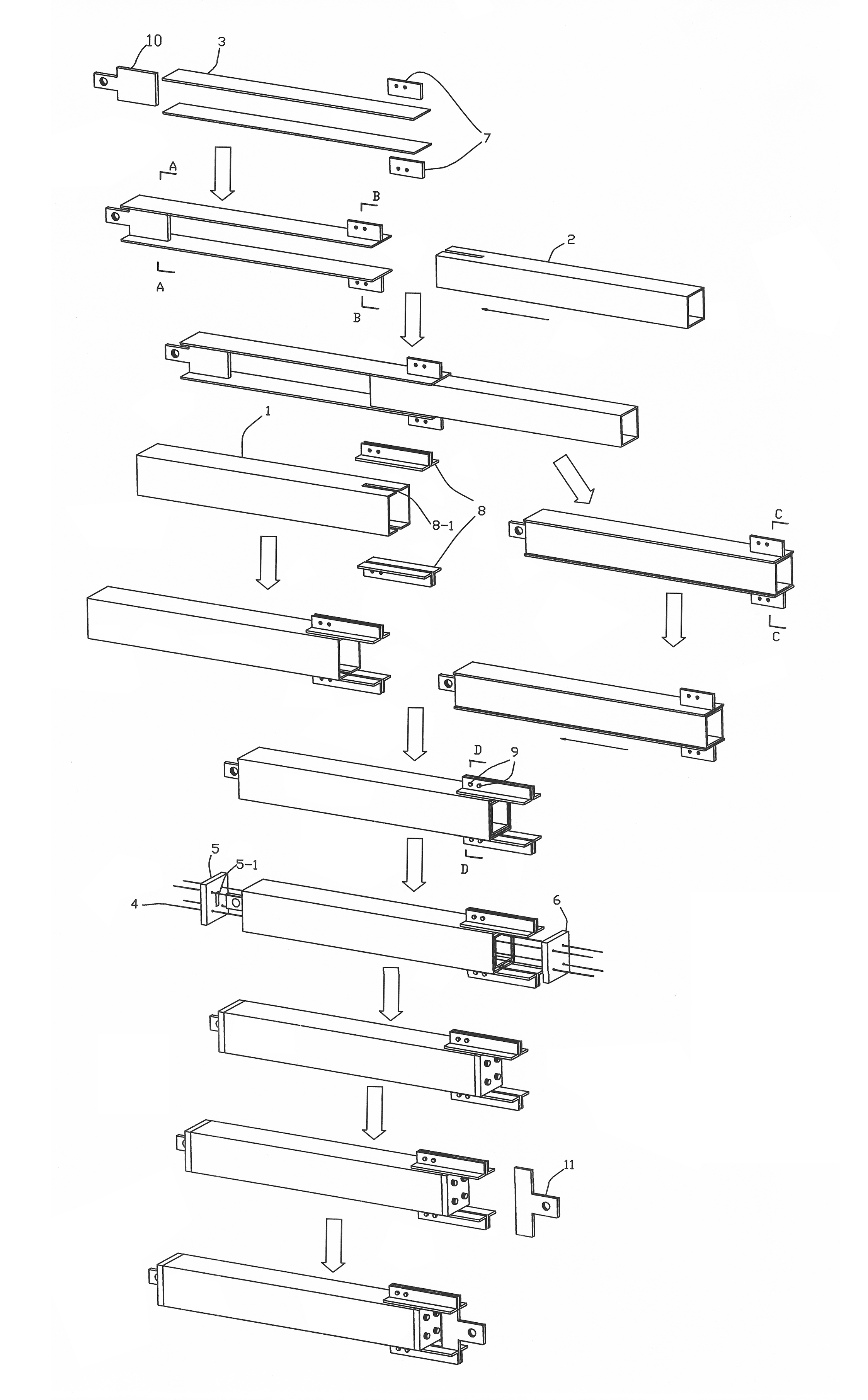

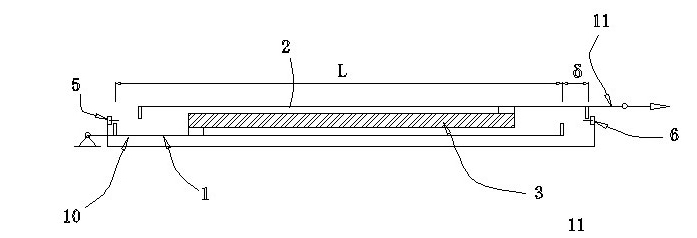

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, the anti-buckling support member of this embodiment consists of a square outer sleeve 1, a square inner sleeve 2, a first end plate 5, a second end plate 6, a first convex connecting plate 10, and a second convex connecting plate. plate 11, two energy-dissipating inner core plates 3, multiple reset ribs 4, two connecting plates 7 and two pairs of angle steels 8, the first convex connecting plate 10 is arranged between the two energy-dissipating inner core plates 3 , and the upper side wall and the lower side wall of the first convex connecting plate 10 are fixedly connected to an energy-dissipating inner core plate 3, and each connecting plate 7 is arranged outside the corresponding energy-dissipating inner core plate 3 and The two are affixed; the outer pair of surfaces of the square outer casing 1 is respectively provided with a pair of angle steels 8, and one end of a pair of angle steels 8 ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 Describe this embodiment, the gap between each energy-dissipating inner core plate 3 of this embodiment and the upper side wall and the lower side wall of the square inner casing 2 is respectively 1-2 mm, and at one end and the energy-dissipating inner core plate 3 Fixed connection, the advantage of this structure is that the square inner casing 2 acts as a restraint member for anti-buckling support to realize the energy dissipation effect of the inner core; at the same time, this structure acts as a self-resetting support for the first end plate 5 and the second end plate 6 and the effect of reset muscle 4 transmission force, reach self-reset purpose with this. Therefore, it is guaranteed that the invention realizes the double effects of anti-buckling support and self-resetting support. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 Describe this embodiment, the gap between the side wall of the square inner casing 2 of this embodiment and the side wall of the square outer casing 1 is 1-2mm, and one end is fixedly connected with the energy dissipation inner core plate 3, the structure of this The advantage is that the square inner sleeve 2 acts as a restraint member of the anti-buckling support to realize the energy dissipation effect of the inner core; at the same time, this structure plays a role in transmitting energy to the first end plate 5, the second end plate 6 and the reset rib 4 in the self-resetting support. Force, in order to achieve the purpose of self-resetting. Therefore, it is guaranteed that the invention realizes the double effects of anti-buckling support and self-resetting support. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com