Contact clip

A technology of contact clips and contact pieces, which is applied in the direction of connections, parts of connecting devices, electrical components, etc., and can solve problems such as large contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

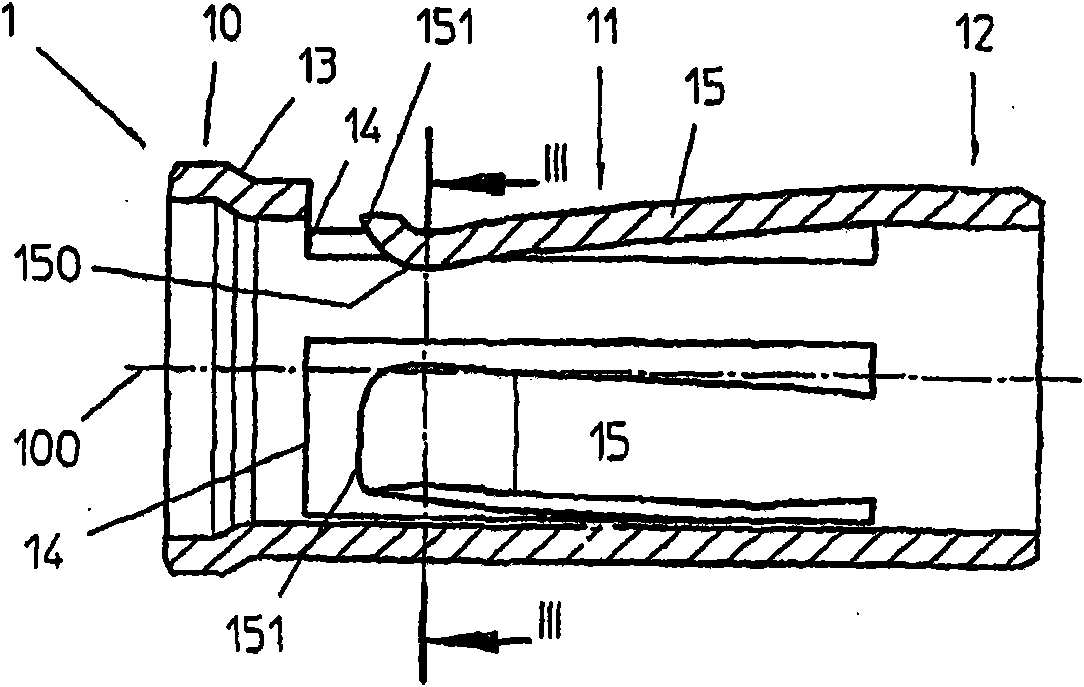

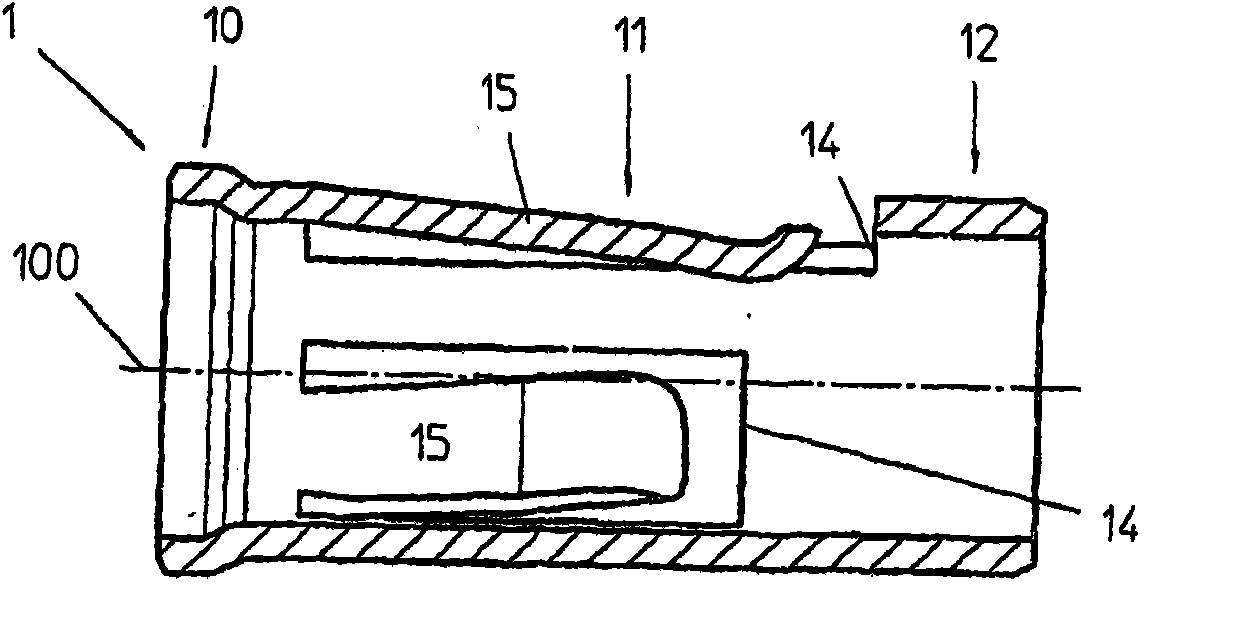

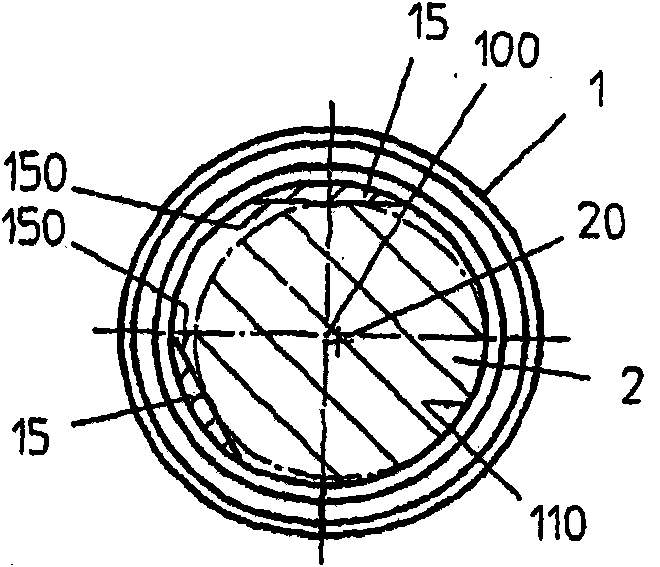

[0015] as in figure 1 The contact clip 1 shown in figure 1 In the embodiment, it includes a fixed part 10, a contact part 11 and an end part 12 from left to right along its length direction.

[0016] As will be seen below, the fixing part 10 consists of a cylindrical ring-shaped part for fixing the contact clip 1 in the corresponding part of the contact. Therefore, the largest dimension of this fixed part 10 is its outer diameter. To fix the fixing part 10 in the contact, in the embodiment shown, requires that the outer diameter of said fixing part is larger than that of the other parts, the frustoconical part 13 being able to engage these diameters.

[0017] In the embodiment shown, the end portion 12 arranged at the opposite end of the contact clip consists of a cylindrical tubular portion intended to be inserted into a corresponding contact piece as will be seen below. in the boot section. For the part 12, its largest dimension is also its outer diameter.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com