Method and controller for controlling position, pressure measurement and safe control of sliding block of forging machine tool

A sliding block position, forging machine tool technology, applied in pressure measurement and safety control, method and controller, controller, sliding block position field of forging machine tools, can solve the problem of low fine-tuning accuracy, inability to strictly time correspondence, loss of machine tool control, etc. problems, to achieve the effect of streamlining the structure of the monitoring system, realizing product quality control, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

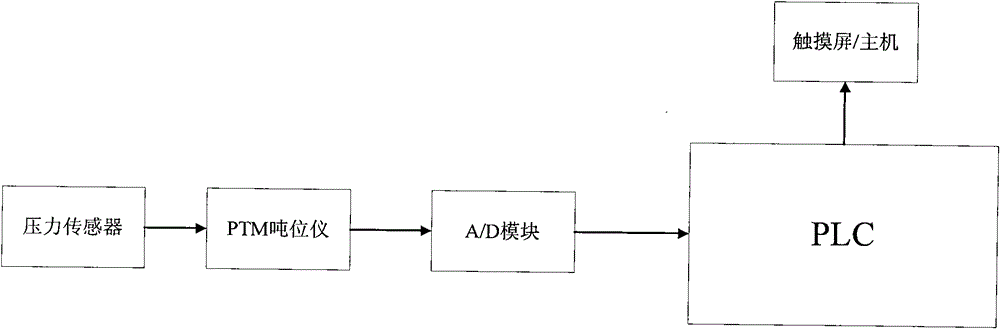

[0038]The control method of the present invention integrates the position detection of the slider and the pressure monitoring of the slider into one controller, collects the position of the slider and the pressure of the slider at the same time, and corresponds the position and pressure according to time to obtain a position-pressure curve. First By collecting the position and pressure data during normal processing many times, the obtained position-pressure curve is set as the standard curve, and the position and pressure are collected in real time during the subsequent processing, and compared with the standard curve, if it is within the set error range Within, it means that the produced workpiece is qualified, if it exceeds the error range, it means that the produced product is a waste product;

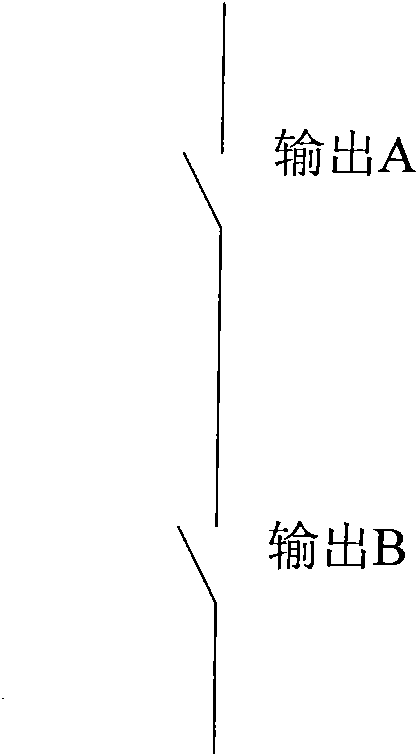

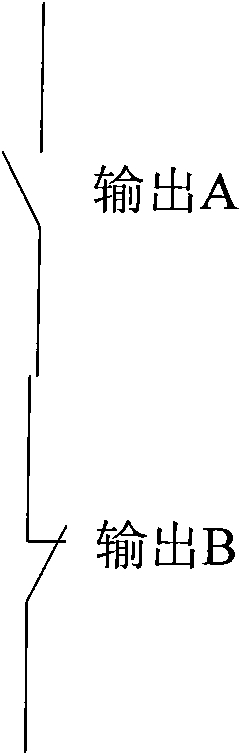

[0039] The method to avoid the failure of single output point is: adopt double-loop output, and adopt serial connection between the two loops, as shown in Figure 2(a); if one loop fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com