Cartridge and electrophotographic image forming apparatus

A technology of electrophotography and imaging equipment, which is applied in the field of electrophotography and imaging equipment, and can solve problems such as increased assembly difficulty, limited material selection, and increased man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0069]

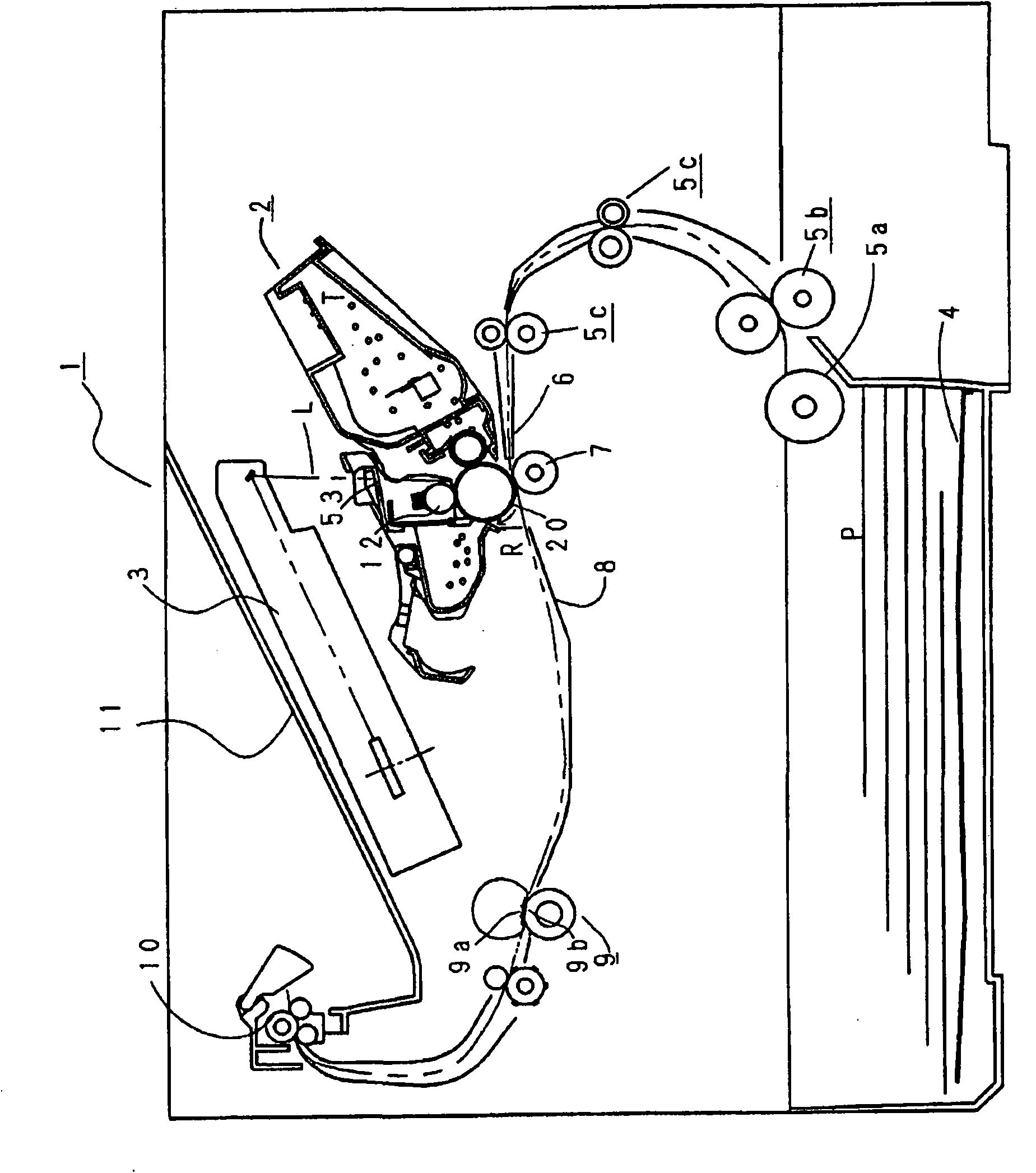

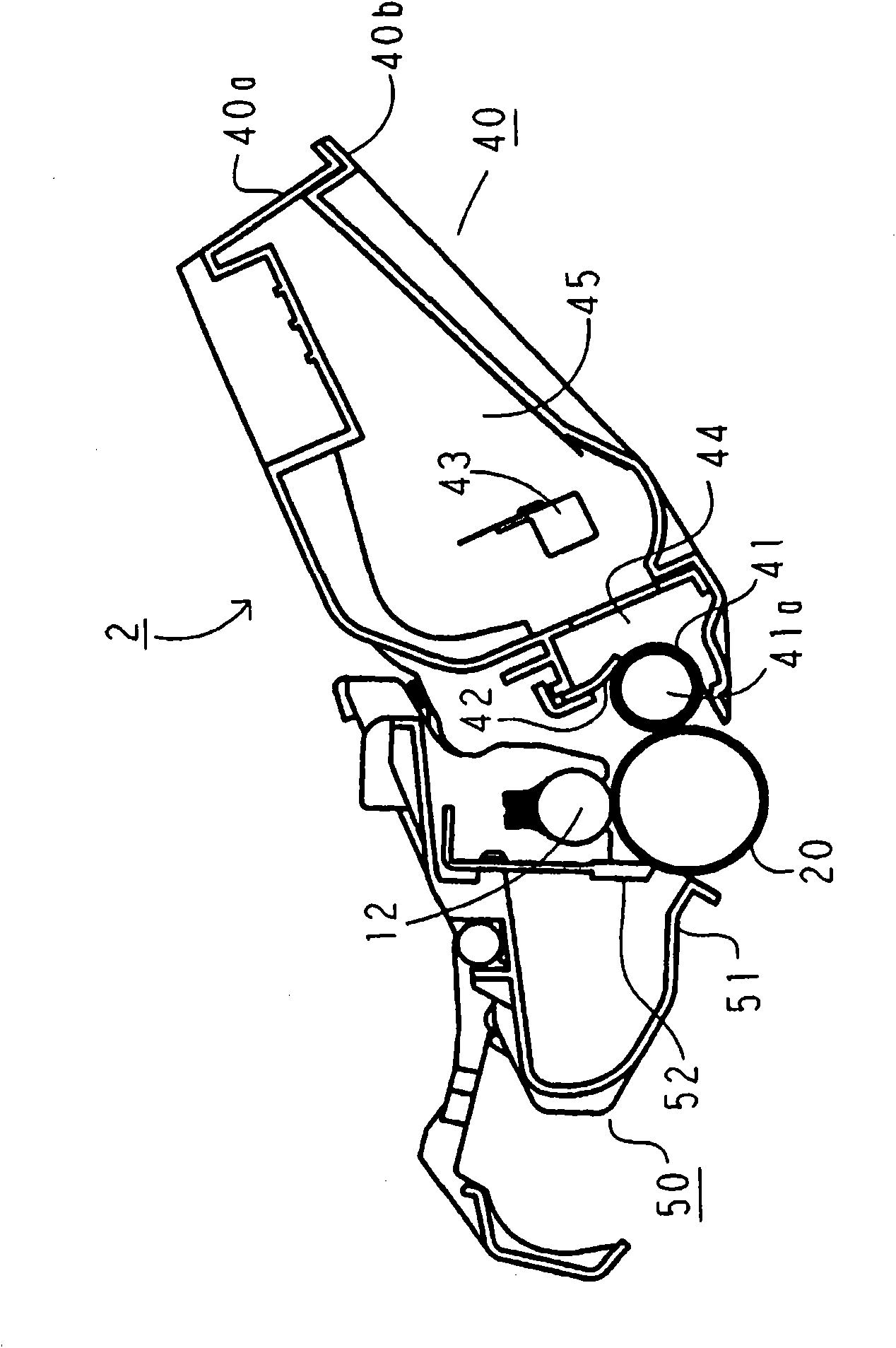

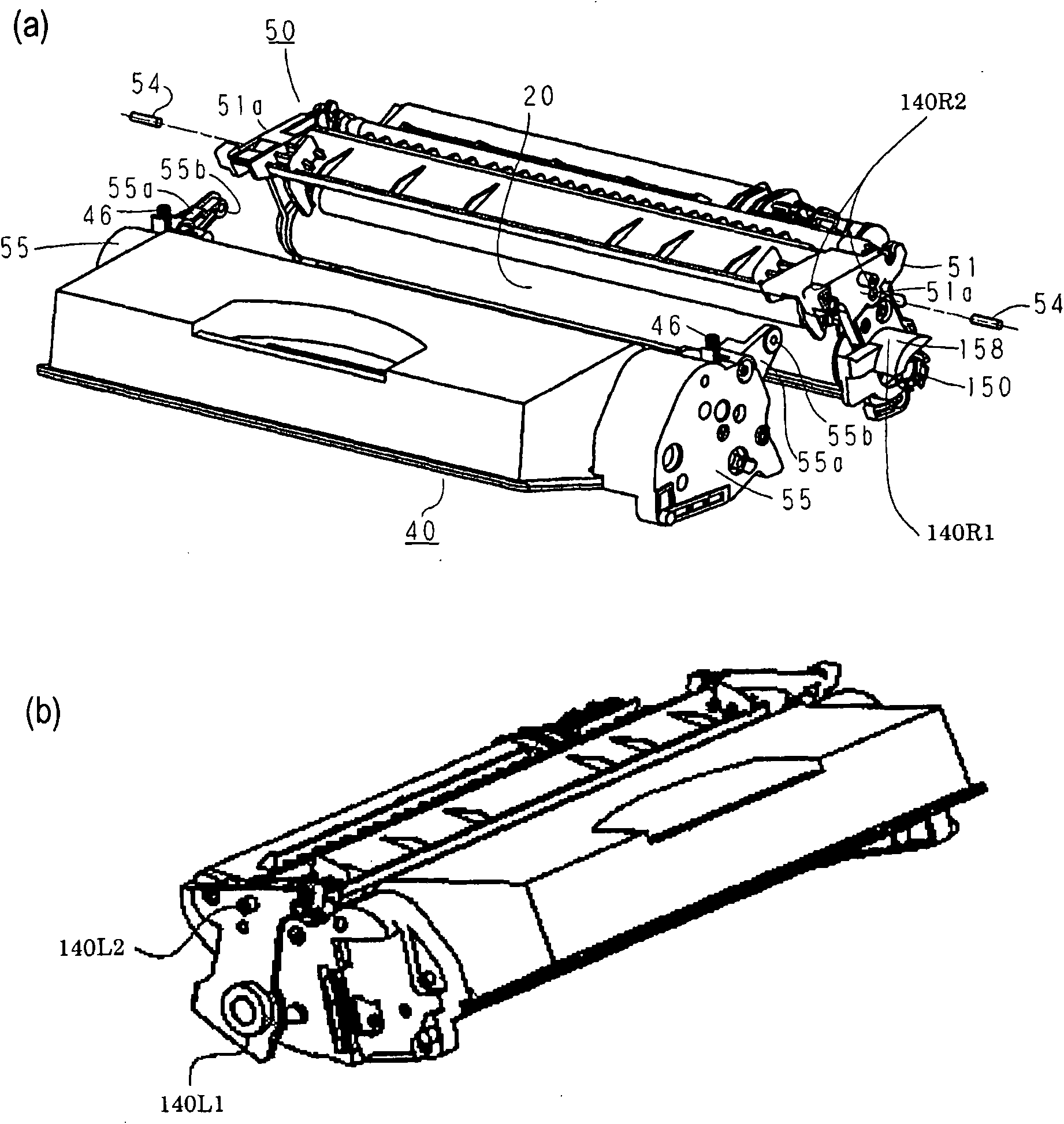

[0070] figure 1 is a sectional view of the main assembly 1 and the process cartridge 2 of the electrophotographic image forming apparatus according to this embodiment. figure 2 is a sectional view of the process cartridge 2 according to this embodiment. The following will refer to figure 1 and figure 2 The general arrangement of the imaging device and the imaging process will be described.

[0071] In this image forming apparatus, a process cartridge (cartridge) 2 is detachably mountable to a main assembly 1 of an electrophotographic image forming apparatus. The electrophotographic image forming apparatus is an electrophotographic type laser printer. When the cartridge 2 is mounted on the main assembly 1 , an exposure device (laser scanning unit) 3 is provided on the upper portion of the cartridge 2 . A lower portion of the cassette 2 is provided with a sheet tray 4 for accommodating recording materials (sheets) P. As shown in FIG. Further, the main assembly...

no. 2 example

[0209] will now refer to Figure 44-46 The device according to the second embodiment will be described. The basic structure of the device of this embodiment is the same as that of the above-mentioned embodiments, therefore, redundant descriptions are omitted for the sake of simplicity. The same reference numerals as in the previous embodiment denote elements with corresponding functions.

[0210]

[0211] These embodiments differ from the first embodiment in the structure of the coupler assembly 156 . In the coupler assembly 156 of the present embodiment, the coupler 150 and the spherical member 160 are directly connected to each other by the connecting portion 150t provided in the coupler 150 and the connecting portion 160c provided for the spherical member 160 .

[0212] Figure 44 (a) is a perspective view showing the coupling assembly of the present embodiment, Figure 44 (b) is a sectional view showing the connection of the coupler 150 and the spherical member 160 ....

no. 3 example

[0226] will now refer to Figure 47-50 An apparatus according to a third embodiment will be described. The basic structure of the device of this embodiment is the same as that of the first embodiment, therefore, redundant descriptions are omitted for simplicity. The same reference numerals as in the previous embodiment denote elements with corresponding functions.

[0227]

[0228] Figure 47 (a) is a perspective view showing the coupler assembly, Figure 47 (b) is a sectional view showing the coupling assembly.

[0229] These embodiments differ from the first embodiment in the structure of the coupling assembly 156 and the flange 151 . Such as Figure 47 (a) and Figure 47As shown in (b), the coupling 150 of the present embodiment includes a substantially spherical portion 150R provided with a through hole 150r. The pin 155 is inserted into the through hole 150r, and is fixed by insertion pressure or the like between the through hole 150r and the pin 155, so that opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com