Wavelet analysis-based grinding machining working condition detection system and method thereof

A wavelet analysis and detection method technology, applied in the field of mechanical processing, can solve problems such as processing efficiency and quality impact, workpiece burns, workpiece and tool damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

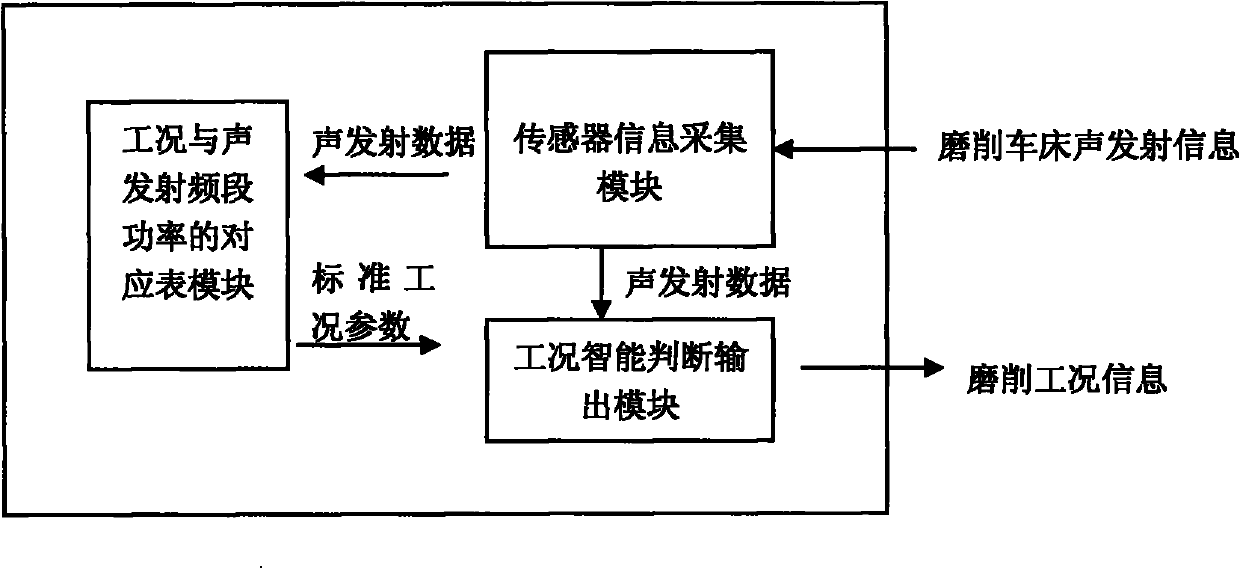

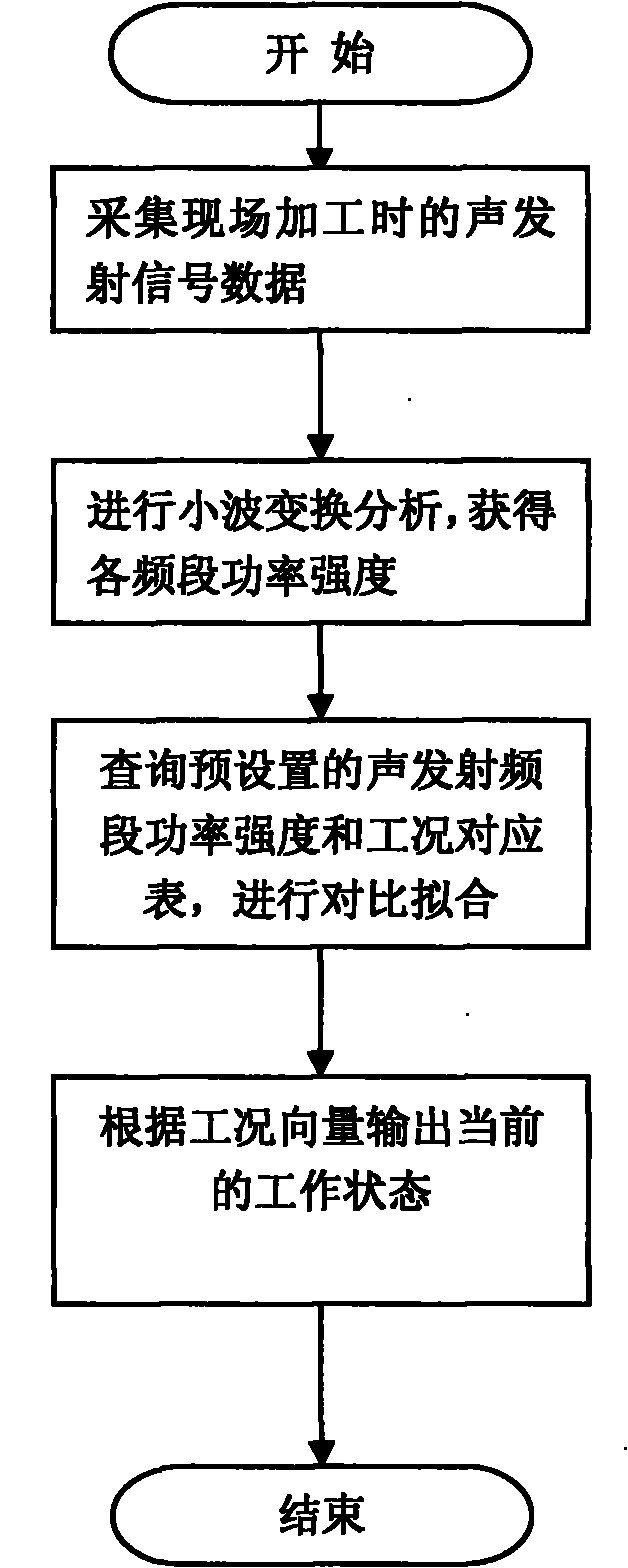

[0087] The present invention is actually applied to the digital control system of the grinding machine to detect the grinding processing conditions in real time, combined with the processing flow figure 2 , and the specific implementation steps are described as follows:

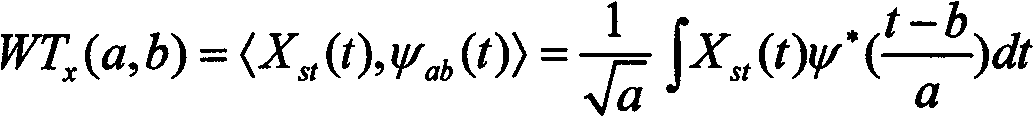

[0088] 1. First construct the correspondence table between working conditions and acoustic emission frequency band power. Under the experimental conditions, the sampling frequency fs of the grinding process detection system based on wavelet analysis is set to 1MHz, the sequence length N is set to 2000, the number of frequency bands m is set to 20, the wavelet base is selected as db10, and the decomposition scale for 20.

[0089] 2. Start the grinding process of the grinding machine, and repeatedly contact and disengage the tool and the workpiece.

[0090] 3. Start the system to collect the acoustic emission signal X when the cutting tool is in contact with the workpiece t , collect 100 sets of data X ti ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com