Method for testing tensile modulus of brittle material

A technology for tensile modulus and brittle materials, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the accuracy of the results is difficult to guarantee, and is not easy, and achieve the effect of simple and cheap operation

Inactive Publication Date: 2010-09-01

CENT SOUTH UNIV

View PDF4 Cites 55 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, how to ensure that the strain gauge is just attached to the center of the sample tension area and completely perpendicular to the tension direction during the strain gauge pasting process is not easy to do, so the accuracy of the obtained results is sometimes difficult to guarantee

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

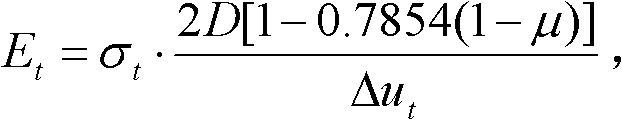

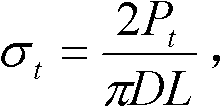

The invention discloses a method for testing tensile modulus of a brittle material, which is characterized by comprising the following steps of: arranging a test sample on a Brazilian split tester; symmetrically applying line load to the test sample in the radial direction of the test sample; measuring the total displacement of center of the test sample in the diameter direction, wherein the direction of the total displacement is vertical to the load applying direction of the test sample; calculating to obtain the tensile modulus Et of the material according to the following formula, wherein Et is the tensile modulus, sigma t is the Brazilian split tensile strength; Pt is the line load, L is the length of the test sample, D is the diameter of the test sample, Mu is the Poisson's ratio, and Delta ut is the total displacement of the center of the test sample in the diameter direction. The method for testing the tensile modulus of the brittle material can guarantee more accurate test result.

Description

technical field The invention relates to a method for testing the tensile modulus of brittle materials. technical background The tensile properties (including tensile strength, tensile modulus, etc.) of brittle materials such as rocks and concrete are very important properties. The methods currently used to determine the tensile parameters of brittle materials mainly include direct tensile test and indirect tensile test. Due to the difficulty in processing the samples for the direct tensile test, the indirect tensile test method is usually used for the tensile test. The Brazilian split test is currently the most commonly used indirect tensile test method. This method was recommended by the International Society for Rock Mechanics (ISRM) in 1978 as a method for determining the tensile strength of rock. This method is also one of the standard methods developed by the American Society for Testing and Materials. In China, the national standard "Engineering Rock Mass Test Met...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08

Inventor 宫凤强李夕兵

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com