Device for sleeving bearing ring

A technology of bearing rings and bearing outer rings, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of easy failure, small application scope, complex mechanism, etc., to achieve simplified mechanism, convenient model change, no need The effect of debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

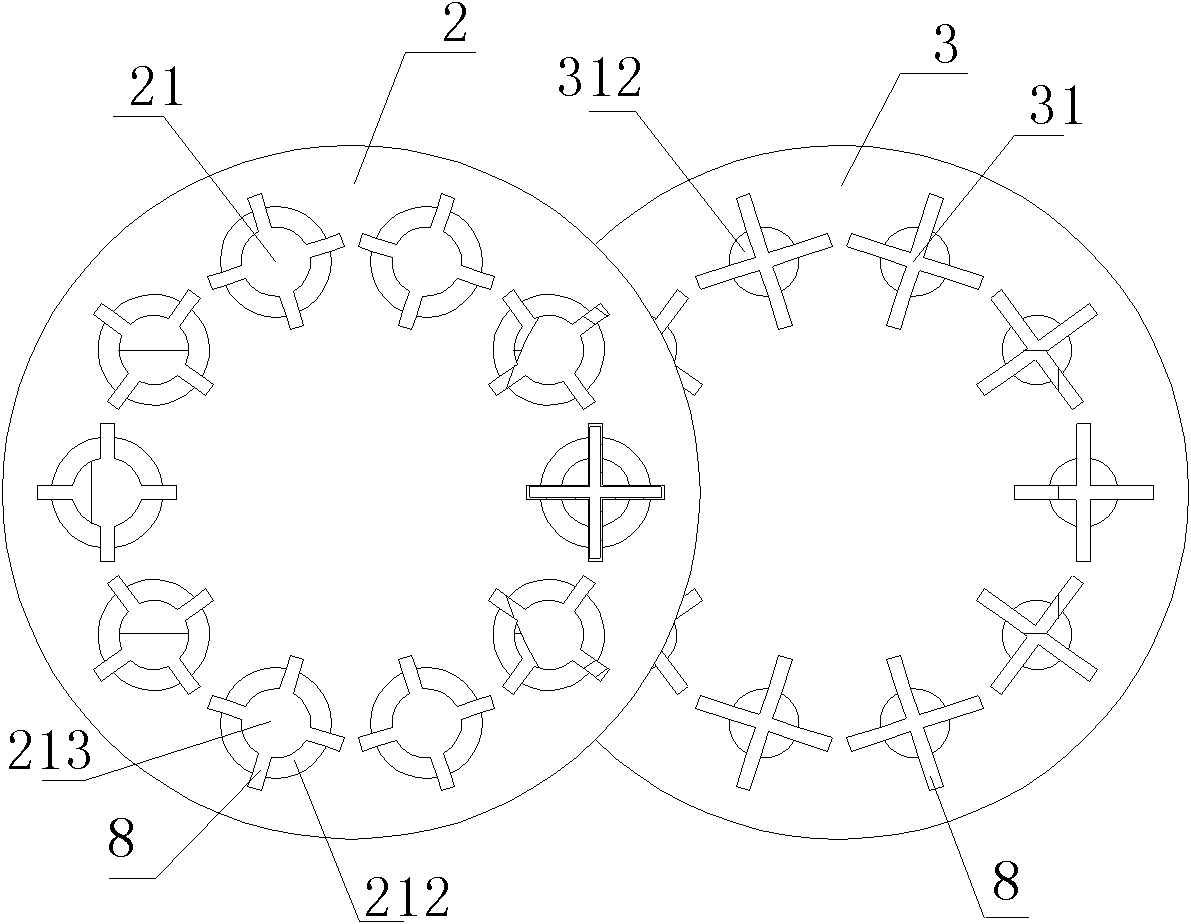

[0037] With reference to accompanying drawing, further illustrate the present invention:

[0038] The assembly device of the bearing ring includes a frame 1, and the frame 1 is provided with:

[0039] The outer ring storage tray 2 carrying the outer ring of the bearing and the inner ring storage tray 3 carrying the inner ring of the bearing are the measuring mechanisms for measuring the size of the ferrule respectively, and the measured ferrules are respectively sent to the transfer material of the corresponding storage tray Mechanism, a combination mechanism for combining the inner and outer rings, and a discharge mechanism for discharging the combined rings; the storage trays 2 and 3 are respectively linked with the respective controllable motors 6 and 7, and the two Each of the controllable motors is controlled by a controller that can record the position of the incoming ferrule, and can automatically select the inner and outer rings to prepare for matching. The controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com