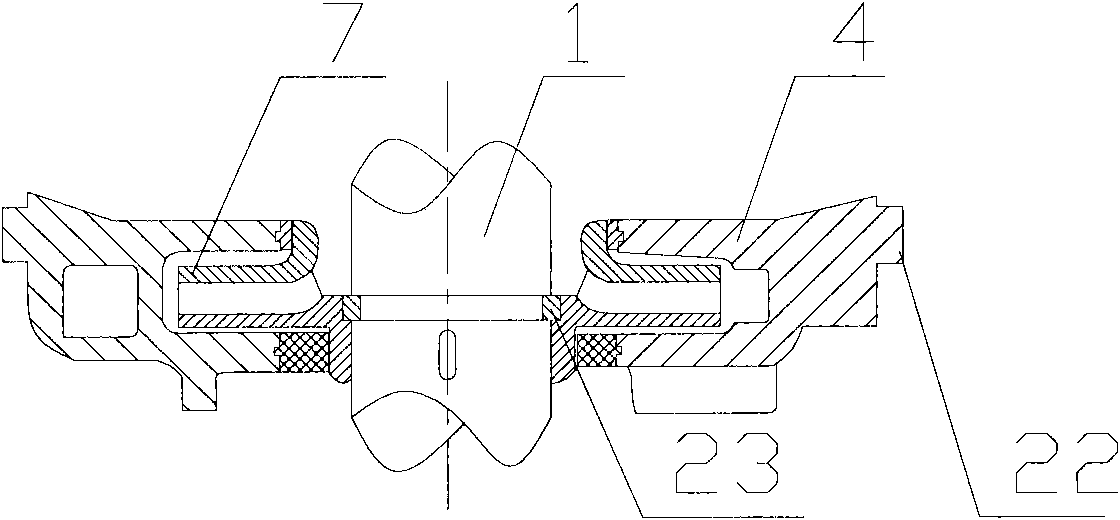

Internal shell split centrifugal charging pump

A technology of inner shell and form, which is applied in the field of open centrifugal upper charging pump, can solve the problem that the material properties cannot meet the chemical and volume control system of nuclear power plants, and achieve the effect of good thermal shock resistance and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, innovative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0023] The top charge pump is one of the main equipment of the chemical and volume control system of the primary circuit of the nuclear power plant, and its functions are as follows:

[0024] When the reactor is in normal operation, the pump operates under the top-fill condition, providing boric acid-containing top-fill water for the primary circuit, and at the same time providing shaft seal water for the mechanical seal of the main pump. When a loss of water accident such as a breach occurs in the main circuit of the reactor, the top charge pump operates under high-pressure safety injection conditions to inject water into the reactor to prevent further expansion of the accident and ensure the safety of the reactor.

[0025] environmental cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com