Active material with high Zr proportioning and preparation method thereof

An active material and active technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of no breakthrough, the inability to improve the electrocatalytic performance, and the inability to apply Ru-Zr oxides, so as to improve the electrocatalytic activity, The effect of low cost and simple preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

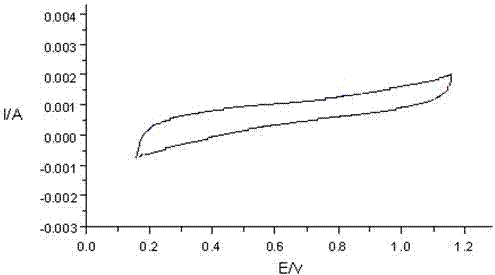

[0027] Preparation of Ru-Zr mixed oxide material with high Zr ratio, ruthenium trichloride and ZrCl 4As the source material, weigh each source material according to the ratio of Zr:Zr+Ru molar ratio of 3:10, and dissolve them in ethanol solution respectively, use ultrasonic vibration to make them evenly dispersed, and mix the two evenly after the solid drug is fully dissolved , so that the concentration of the solute is controlled at about 2mol / L, and allowed to stand for 12 hours to prepare a slurry. Prepare the pure titanium substrate, that is, corrode the pure titanium substrate in a boiling state of 10% oxalic acid solution for 1 hour, take it out, rinse it with distilled water, and dry it. Apply the above-mentioned active slurry on the pre-treated titanium plate with a brush pen, heat and evaporate at 80-100°C, heat and cure at 120-180°C under infrared light, and then oxidize in a box furnace at 300°C After 10 minutes, take out of the furnace and air cool, continue to co...

Embodiment 2

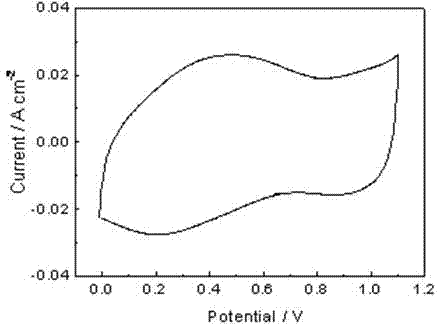

[0029] The Zr-based Ru-Zr mixed oxide material is based on ruthenium trichloride and ZrO(NO 3 ) 2 As the source material, each source material was weighed according to the ratio of Zr:Zr+Ru molar ratio of 6:10, and dissolved in isopropanol solution respectively, and ultrasonically oscillated to make it evenly dispersed. After the solid drug was fully dissolved, the two Mix evenly so that the concentration of the solute is controlled at about 3.5mol / L, and let it stand for 12 hours to prepare a coating solution. Apply the above active slurry on the pre-treated titanium plate (see example 1) with a brush pen, heat and evaporate at 80~100°C, and then heat and cure under infrared light at 120~180°C Oxidize in a box furnace for 10 minutes, leave the furnace to air cool, continue coating, repeat the above operations until the ruthenium content on the titanium base surface reaches 10g / L, anneal at 300°C for 1 hour after the last coating and drying, and cool out of the furnace. Meas...

Embodiment 3

[0031] The Zr-based Ru-Zr mixed oxide material is based on ruthenium trichloride and ZrO(NO 3 ) 2 As the source material, weigh each source material according to the ratio of Zr:Zr+Ru molar ratio of 8.5:10, and dissolve them in butanol solution respectively, use ultrasonic vibration to make them evenly dispersed, and mix the two after the solid drug is fully dissolved Evenly, so that the concentration of the solute is controlled at about 2.2mol / L, and it is left to stand for 12 hours to prepare a coating solution. Apply the above active slurry on the pre-treated titanium plate (see example 1) with a brush pen, heat and evaporate at 80~100°C, and then heat and cure under infrared light at 120~180°C Oxidize in a box furnace for 10 minutes, leave the furnace to air cool, continue coating, repeat the above operations until the ruthenium content on the titanium base surface reaches 6g / L, anneal at 300°C for 1 hour after the last coating and drying, and cool out of the furnace. Me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com