Screen material for 35kV grade high/medium voltage crosslinked cable conductor layer and preparation method thereof

A cross-linked cable, 1.35KV technology, applied to conductive materials dispersed in non-conductive inorganic materials, power cables with shielding layer/conductive layer, etc., can solve the problem that shielding materials cannot be extruded smoothly and cannot be continuously produced for a long time , affecting cable production and other issues, it is difficult to achieve pre-crosslinking, torque balance, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention will be further described:

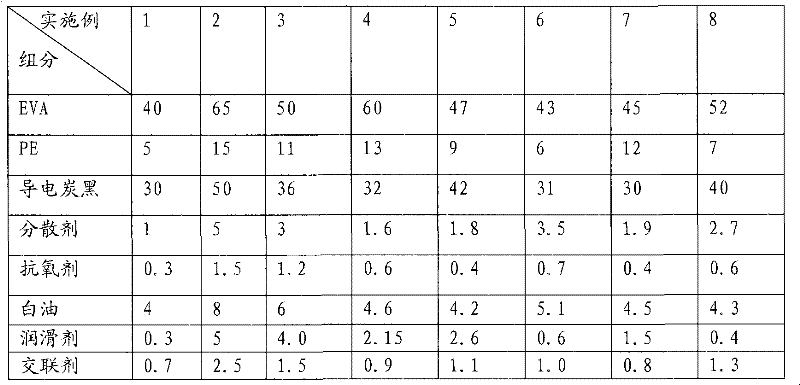

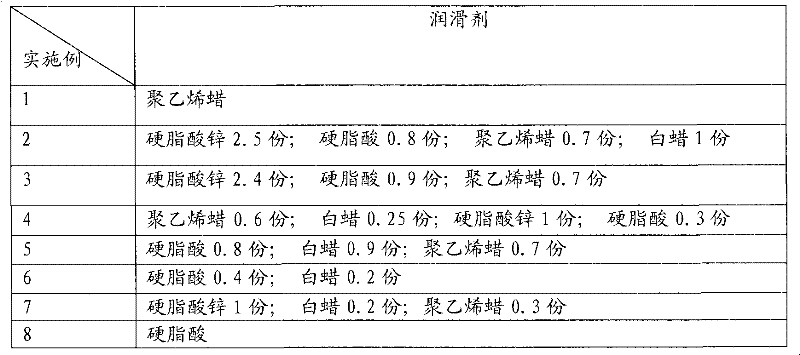

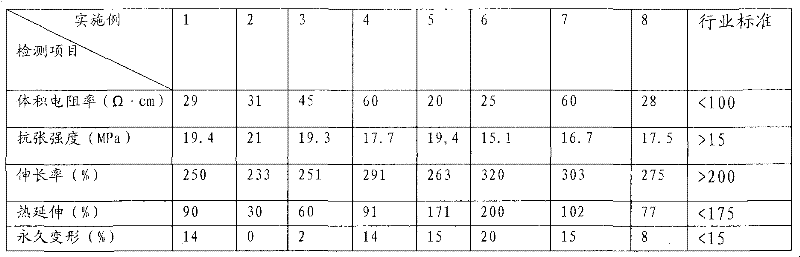

[0023] The parts by weight of components in each embodiment are shown in the table below:

[0024]

[0025] In embodiment 1-6, the EVA used is EVA 18-3, its VA content is between 16%~20%, and melt index is 2~3.

[0026] In Examples 1-6, PE is Q200.

[0027] In Examples 1-6, the conductive carbon black is conductive carbon black 6900, and its DBP value is 100-145.

[0028] The antioxidant that embodiment 1-3 uses is antioxidant 101; What embodiment 4 uses is 0.3 weight part antioxidant 101 and 0.3 weight part antioxidant 300; The antioxidant that embodiment 5-8 uses is antioxidant Oxygen 300.

[0029] The cross-linking agent that embodiment 1-2 uses is BIPB; The BIPB and TAIC of the same parts by weight that embodiment 3-4 uses; Embodiment 5,6 use weight ratio is 1.5: 1 TAIC and BIPB; Embodiment 7- 8 DCP and BIPB were used in a weight ratio of 1.2:1.

[0030] The dispersant is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com