Secondary compaction device of garbage compression box

A garbage compression and secondary compaction technology, which is applied in garbage transmission, garbage collection, storage devices, etc., can solve the problems that affect the city appearance, urban sanitation, clean development, visual and olfactory pollution, etc., to achieve The effect of solving air pollution and environmental pollution, compressing and compacting, and protecting environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

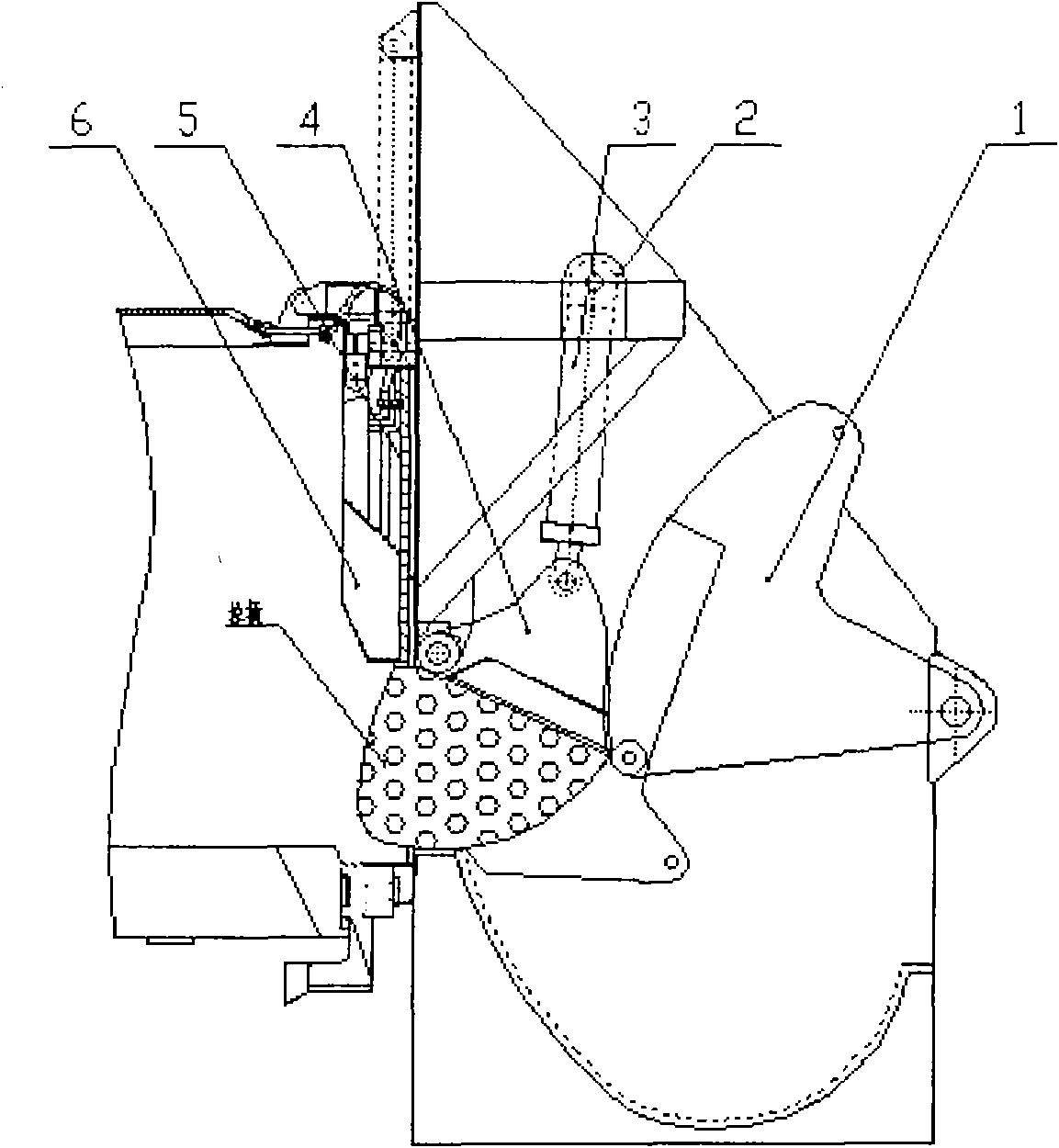

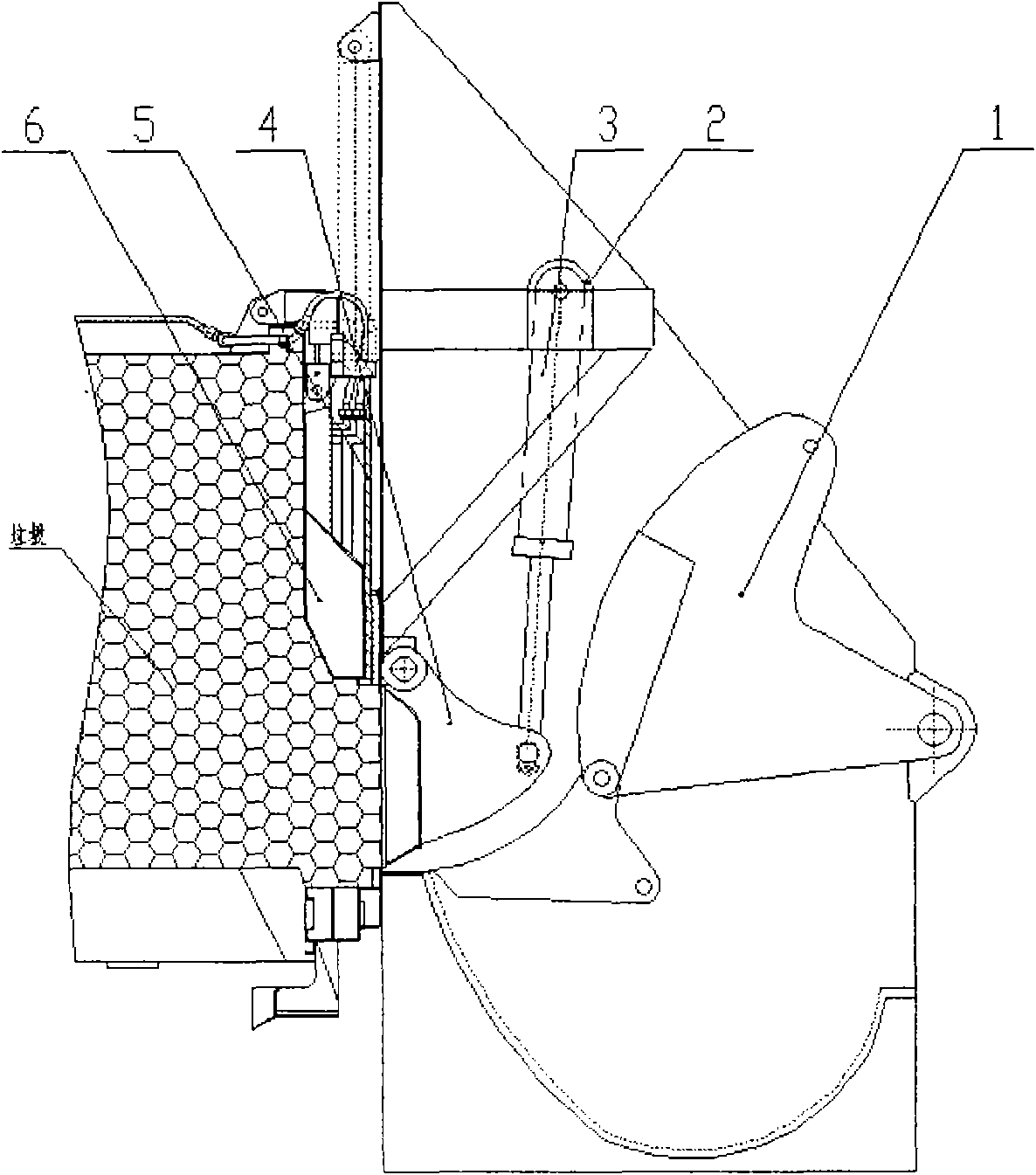

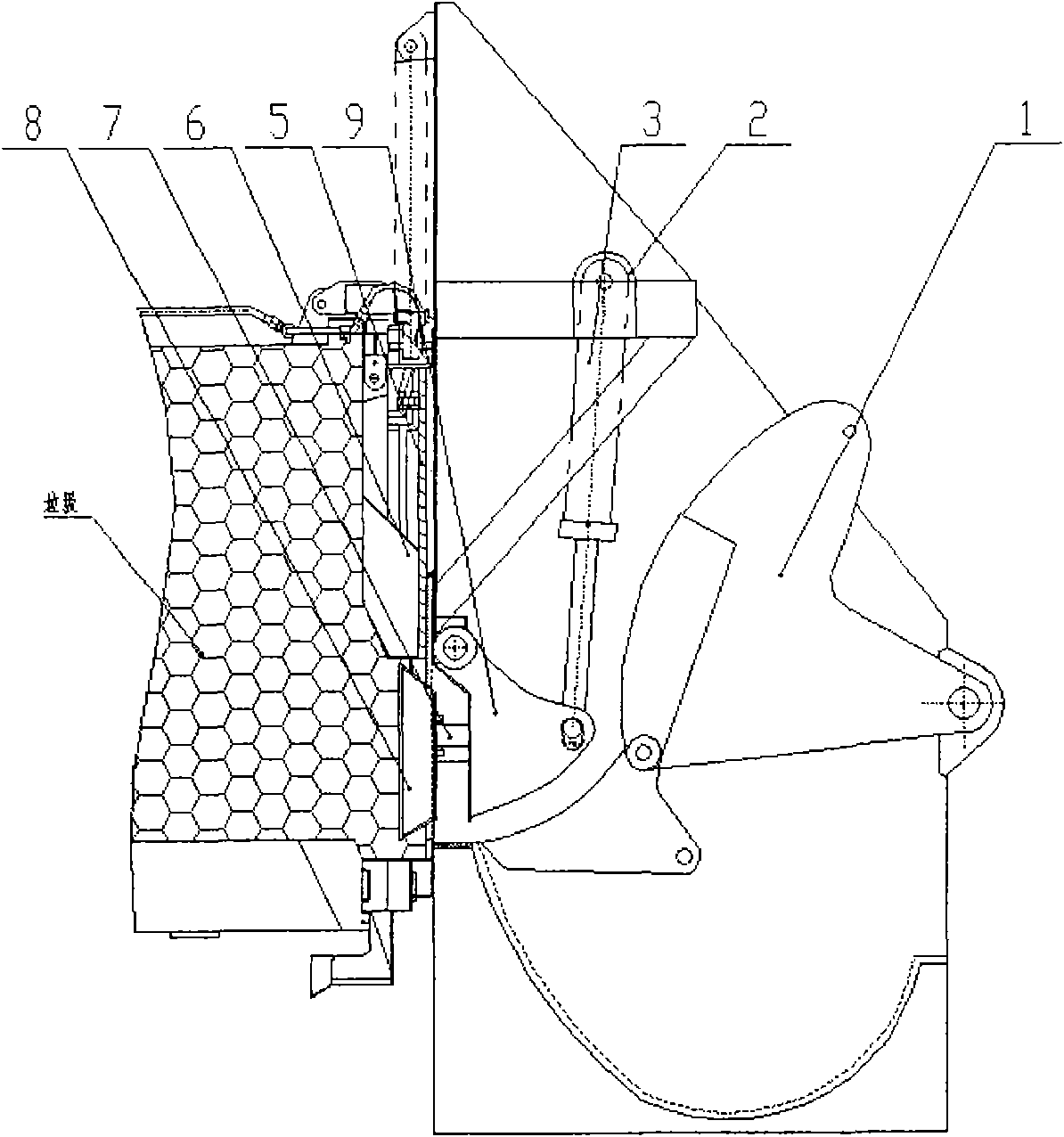

[0026] The working process of the detachable garbage compression transfer station equipment: when the secondary compaction device of the garbage compression box starts to work, see figure 1 ;See when first compacting garbage figure 2 ;See when you compress garbage a second time image 3 ; The secondary compaction device of the garbage compression box is retracted, and when the main gate is closed, see Figure 4 .

[0027] The specific working process above is: after the extrusion plate and the crushing plate on the compressor 1 squeeze and crush the rubbish, and transport the rubbish to such as figure 1 In the position shown, the piston rod of the compression cylinder 3 hinged on the compression cylinder support 2 stretches out to push the compression plate assembly 4, and the compression plate assembly 4 rotates in an arc around the hinge point hinged on the compressor 1 , so as to push the garbage to be compressed into the garbage compression box (see figure 2 ), when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com