Hybrid power drive device

A hybrid power and drive device technology, applied in power devices, hybrid vehicles, pneumatic power devices, etc., can solve problems such as reversing mileage limitation and battery state-of-charge limitation, and achieve the effect of reducing emissions and increasing reversing mileage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

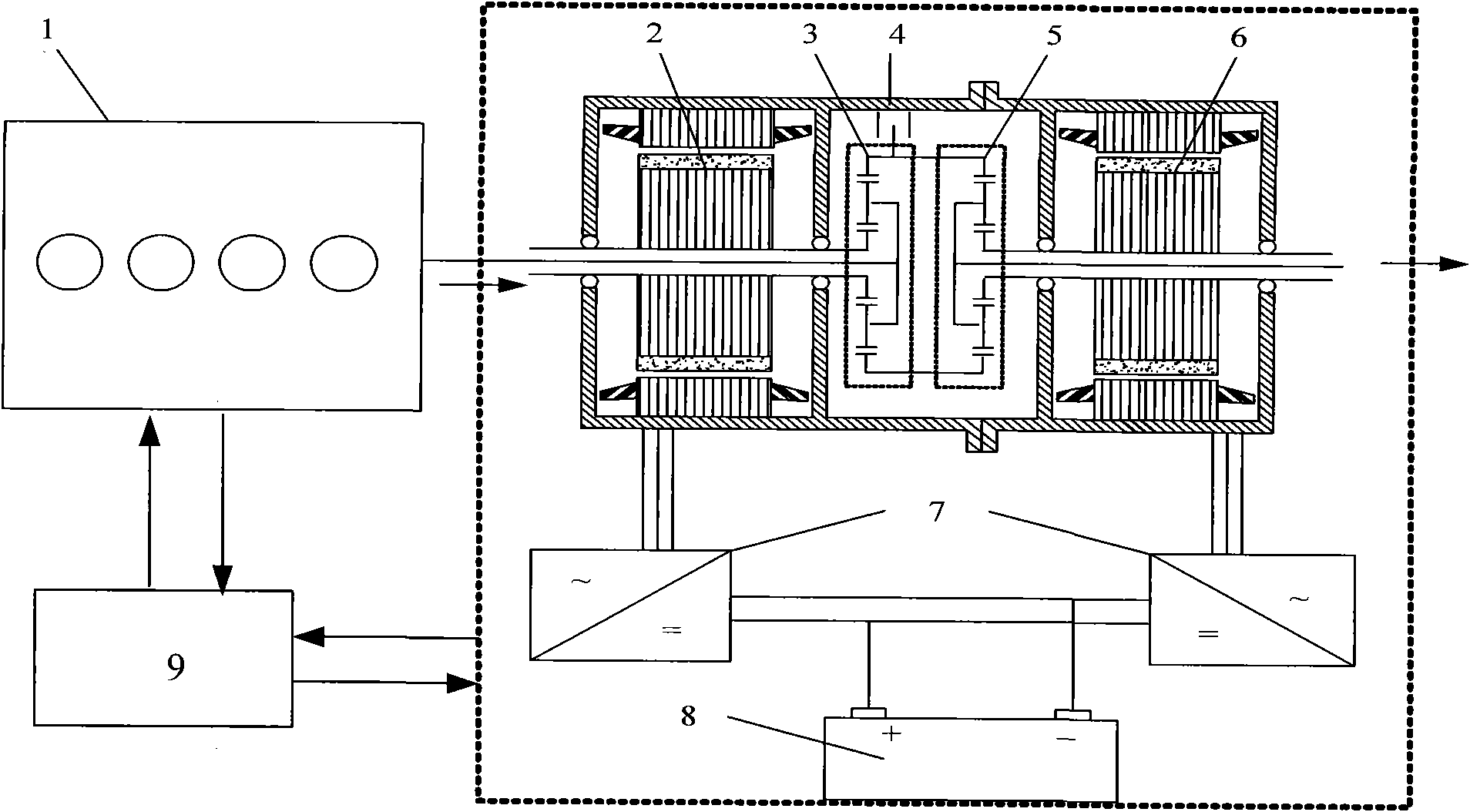

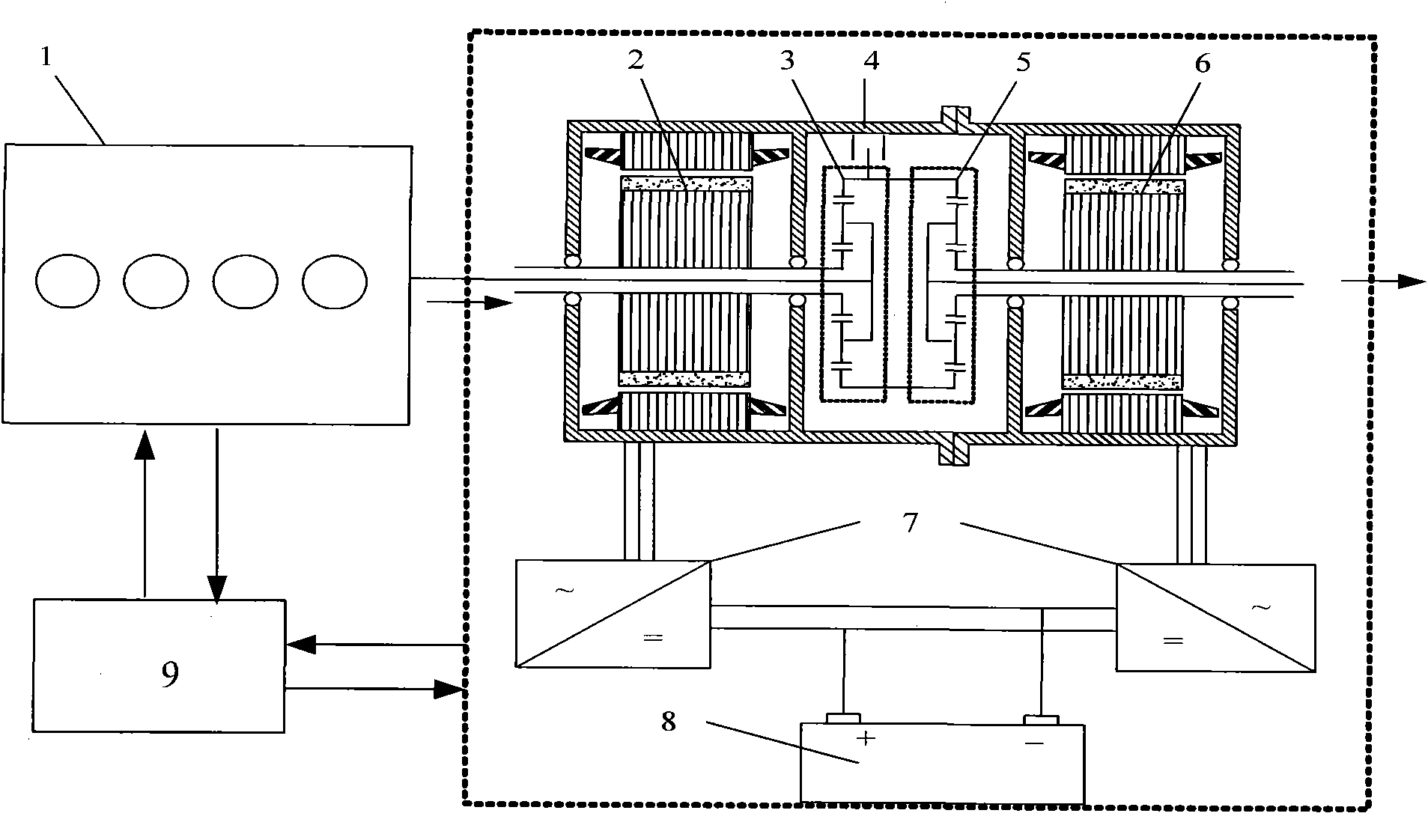

[0011] see figure 1 , a hybrid driving device of the present invention, comprising an engine 1, a generator 2, a front planetary gear mechanism 3, a brake 4, a rear planetary gear mechanism 5, a motor 6, two inverters 7, a battery 8 and a controller 9; The ring gears of the front planetary gear mechanism 3 and the rear planetary gear mechanism 5 are integrated; the planet carrier of the front planetary gear mechanism 3 is connected to the output shaft of the engine 1, and its sun gear is connected to the rotor of the generator 2; the sun gear of the rear planetary gear mechanism 5 The wheel is connected with the rotor of the motor 6, and the power output shaft is connected to the planetary carrier; the brake 4 is installed on the integrated r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com