Oyster rope releaser

A technology of oyster and rope machine, which is applied in fish farming, application, climate change adaptation, etc., and can solve the problems of high labor intensity, low degree of mechanization, and low work efficiency of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

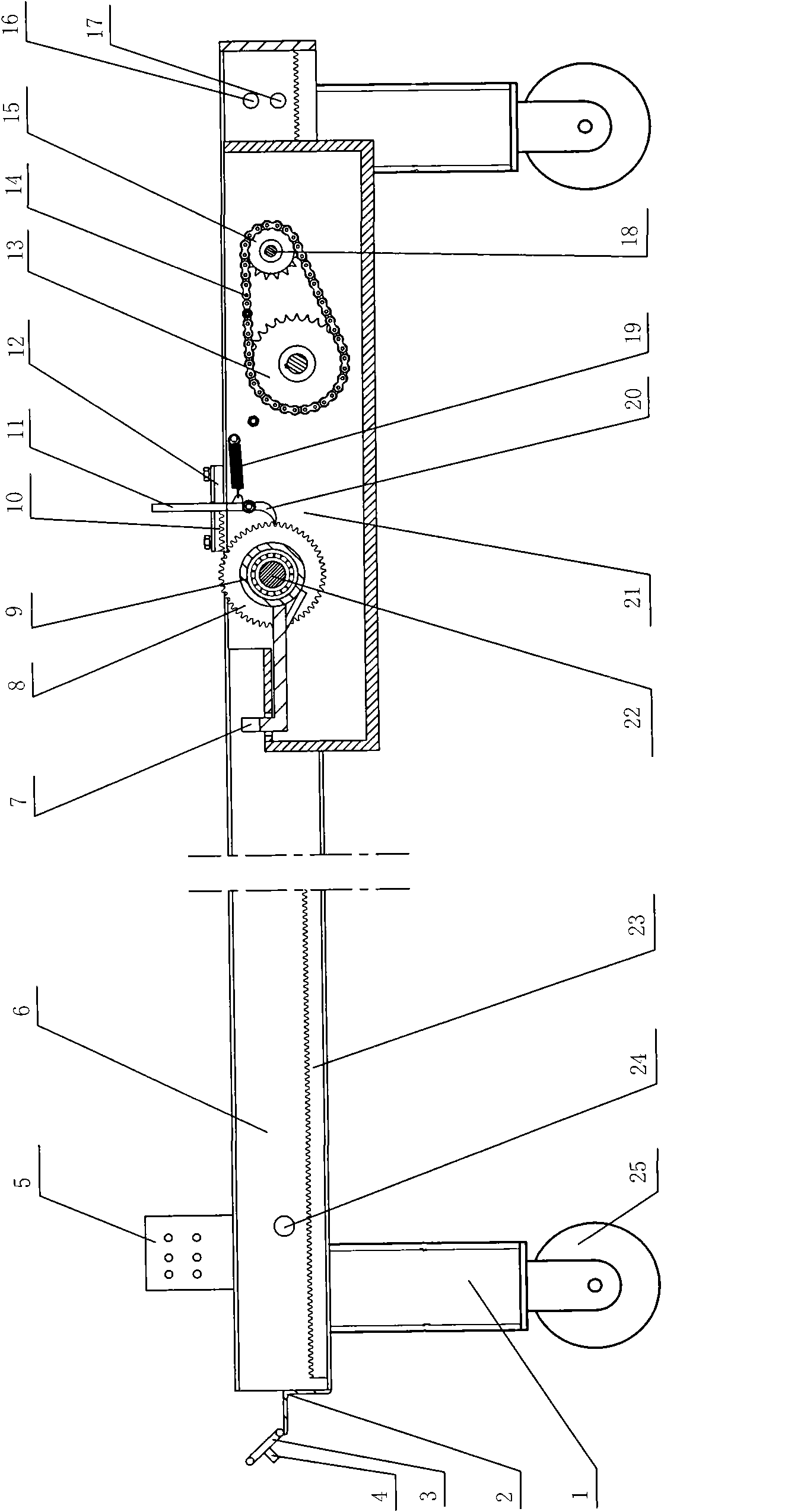

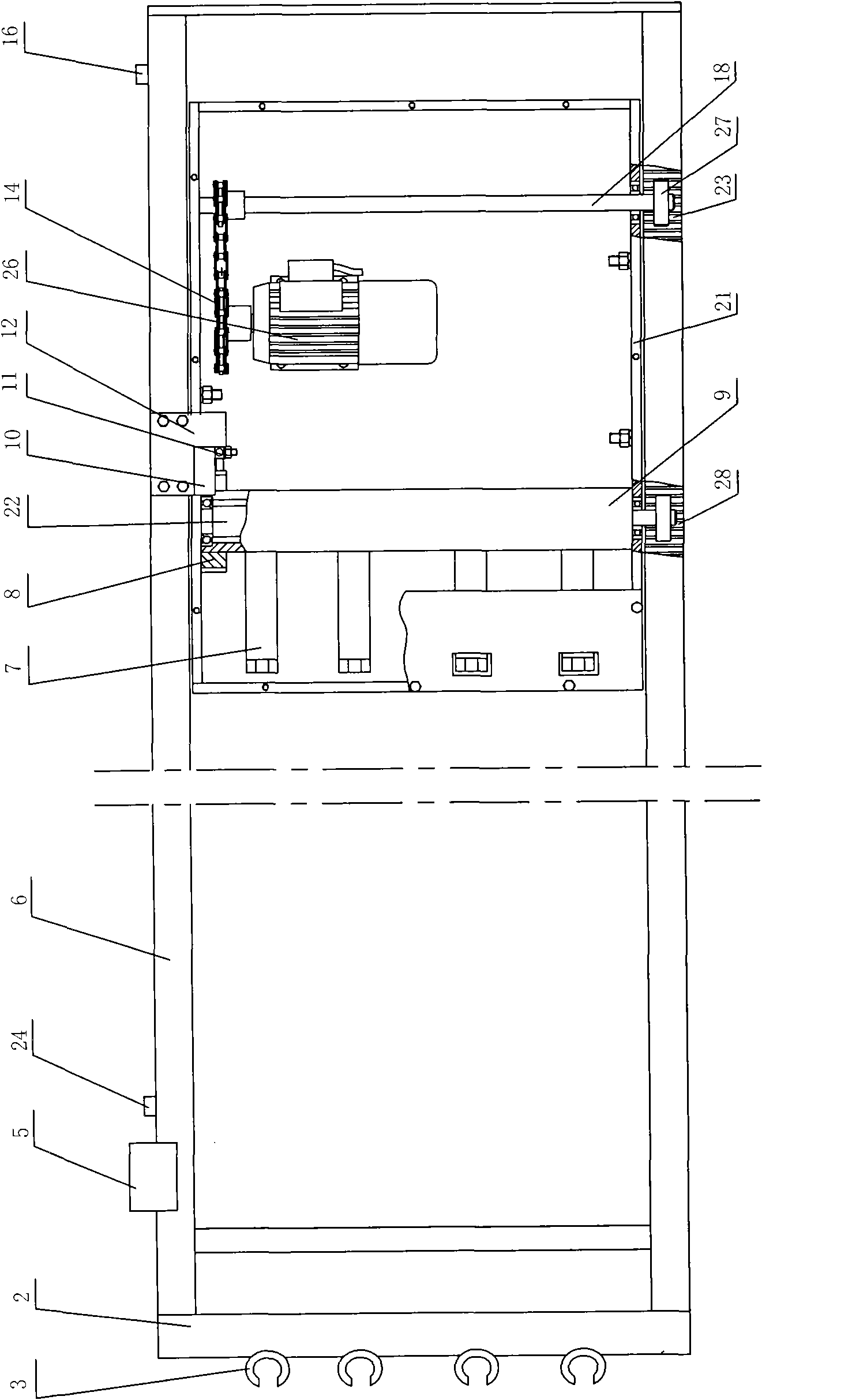

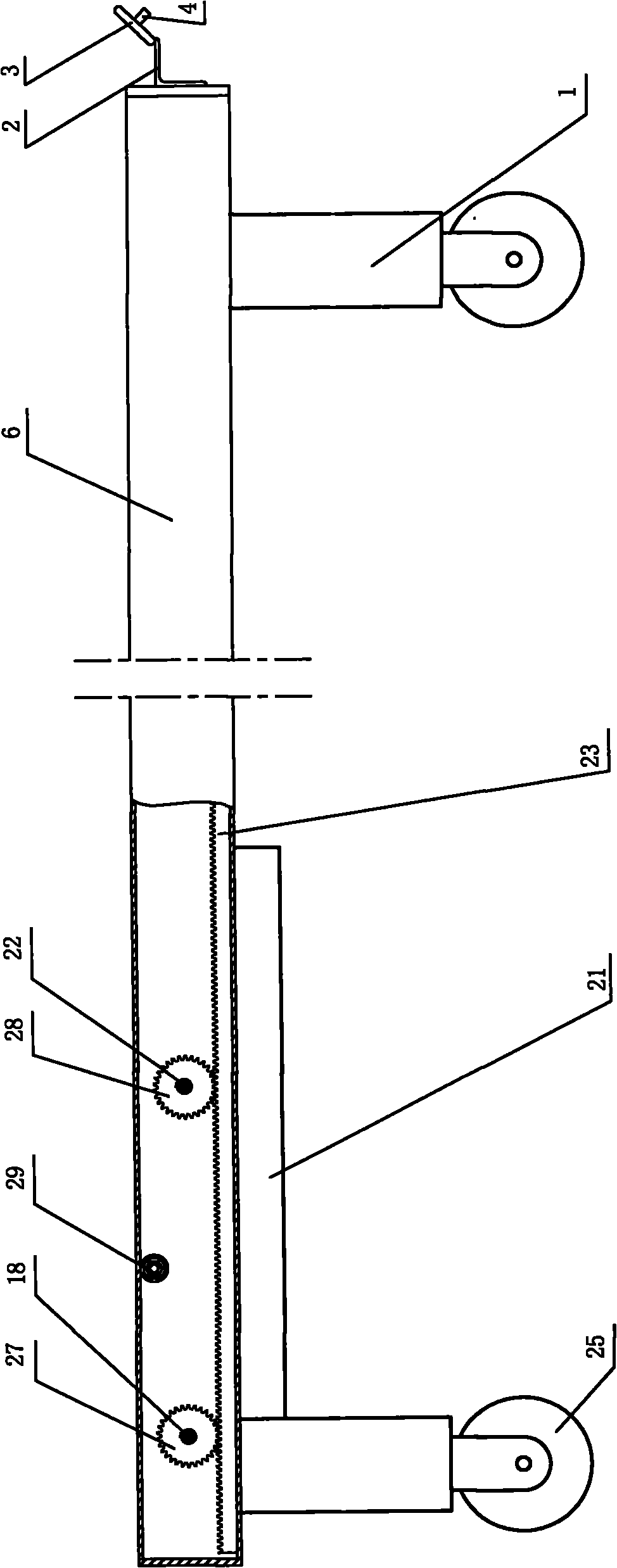

[0024] exist figure 1 , figure 2 , image 3 Among them, an oyster de-rope machine, which includes a support 2 made of angle steel and four oyster separation parts 3, the oyster separation part 3 is a ring-shaped part with an opening, and is welded and fixed on the support 2.

[0025] In order to prevent the oysters clinging on the rope from entering the ring-shaped oyster separation part 3 and pulling the rope, causing the rope to be separated from the ring-shaped oyster separation part 3, a retaining bar is symmetrically welded and fixed on the limiting side of the ring-shaped oyster separation part 3 4.

[0026] exist figure 1 , figure 2 , image 3 Among them, an oyster de-rope machine, which also includes a horizontal frame 6.

[0027] Such as figure 1 , figure 2 , image 3 As shown, the horizontal frame 6 is made up of two parallel grooved guide rails. Its bottom is supported by the bracing frame 1 that is welded and fixed therewith, and walking wheel 25 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com