High pressure discharge lamp ballast, lighting device and lighting system

A high-pressure discharge lamp and lighting device technology, which is applied in the field of lighting systems, can solve problems such as rising costs and complexity, and achieve the effect of sufficient heating

Inactive Publication Date: 2010-08-25

PANASONIC CORP

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in order to realize the above-mentioned method, a detection circuit and a control circuit with a complicated structure are required, and cost increases accompanied by an increase in the number of parts occur.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 1

Embodiment approach 2

Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

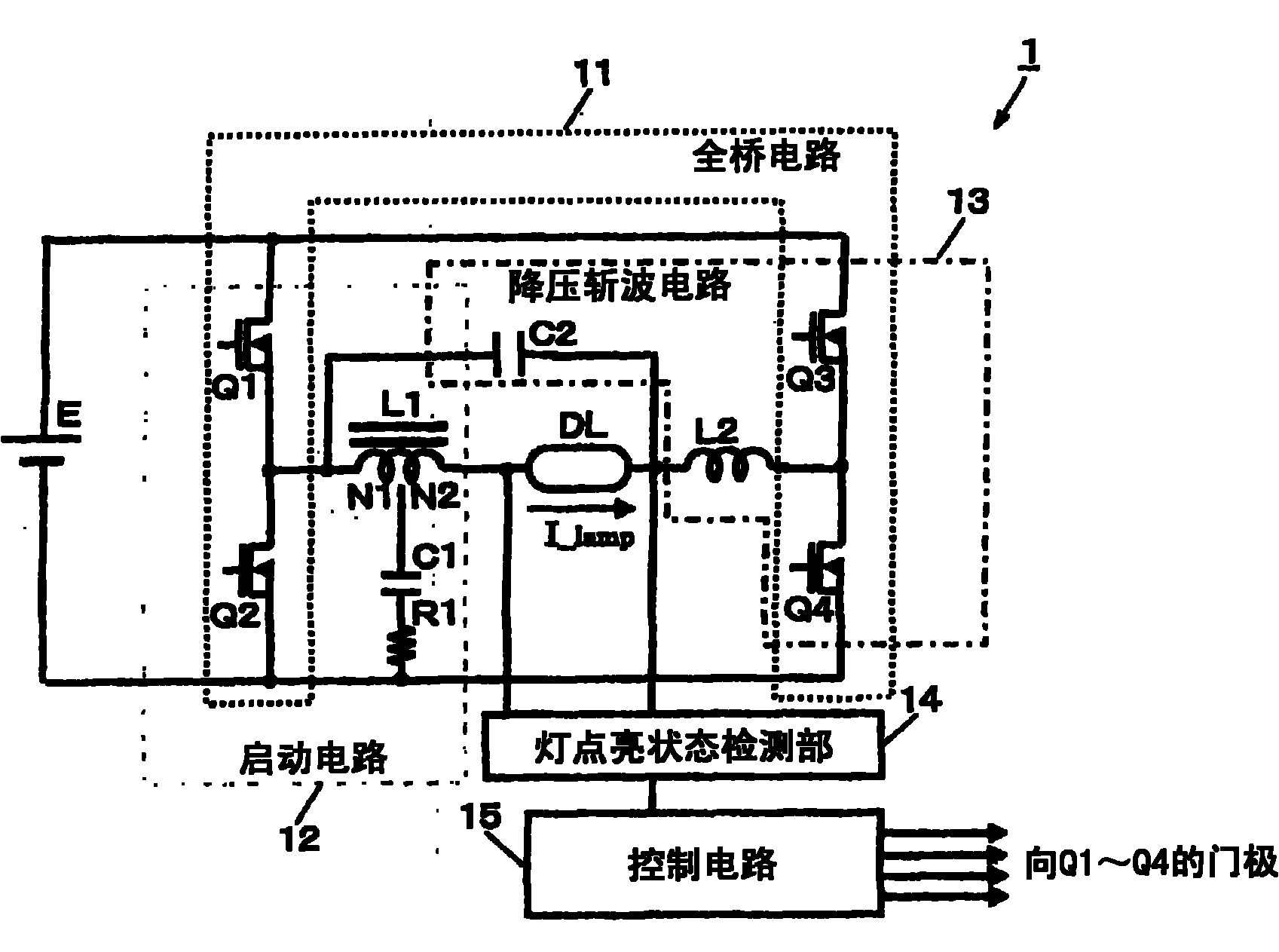

The invention relates to a high pressure discharge lamp ballast, a lighting device and a lighting system, which can meet an electrode require, adequately heat and form a stable discharge without making the circuit structure complex. The high pressure discharge lamp ballast (1) comprises a full-bridge circuit (11) which converts DC power into AC power, a startup circuit (12) which generates a startup high voltage for breaking down the lamp (DL) insulation, a buck chopper (13) which reduces the output voltage of a DC power supply (E) and outputting to the full-bridge circuit (11), a lamp ballast state detection unit (14) which detects the lamp (DL) ballast state, and a control circuit (15) which controls the full-bridge circuit (11) and the startup circuit (13). The control circuit (15) sets the lamp power supply during the electrode heating period when the lamp is started according to an accumulation ballast time detected by the lamp ballast detection unit (14).

Description

technical field The present invention relates to a high-pressure discharge lamp lighting device for lighting a high-pressure discharge lamp, a lighting fixture using the same, and a lighting system constructed of a plurality of lighting fixtures. Background technique Conventionally, high-intensity high-pressure discharge lamps called HID (High-Intensity Discharge) have been widely used mainly for vehicles. In this high-pressure discharge lamp, since discharge needs to be generated in the lamp during lighting, a lighting device including a power conversion circuit that inputs DC power and outputs AC power, and a control circuit that controls the power conversion circuit is required. As a high-pressure discharge lamp lighting device, it has been proposed to set the ignition period (hereinafter referred to simply as "phase 1") in which a control circuit raises the voltage of a power conversion circuit and applies a voltage to a high-pressure discharge lamp to cause dielectric ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H05B41/24

CPCH05B41/382H05B41/2887Y02B20/204Y02B20/00

Inventor 山原大辅小松直树

Owner PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com