Double-speed four-power energy-saving three-phase asynchronous motor

A three-phase asynchronous, motor technology, applied in the field of motors, can solve the problems of low motor efficiency, reduced motor efficiency, and reduced power grid operation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

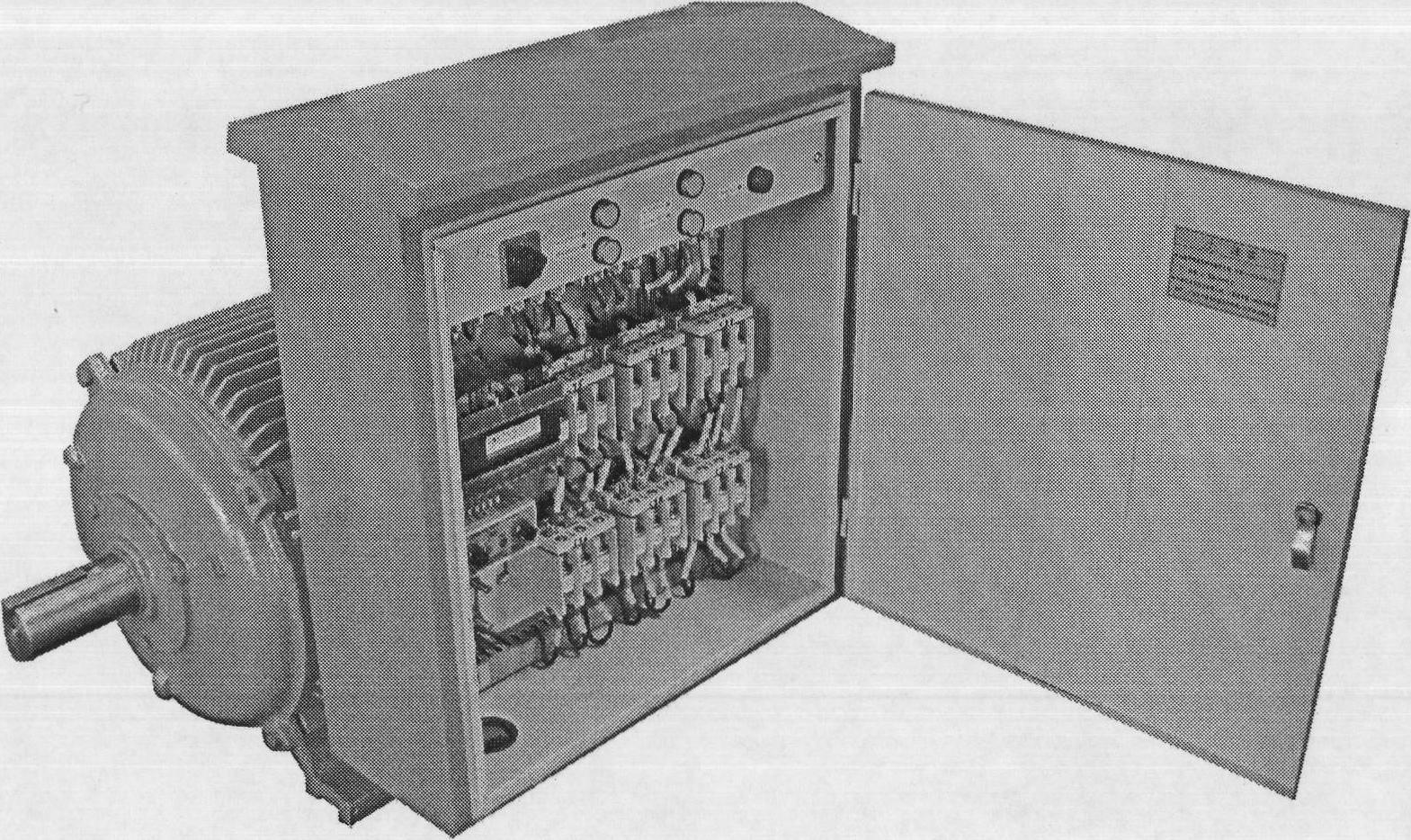

[0013] Fig. 1 is the appearance diagram of the DSGJ two-speed four-power motor product of the present invention: it is composed of an energy-saving motor and a control cabinet. When the pumping unit is used, it is only necessary to firmly install the motor base plate on the foundation with bolts, connect the power supply, and operate according to the instruction manual.

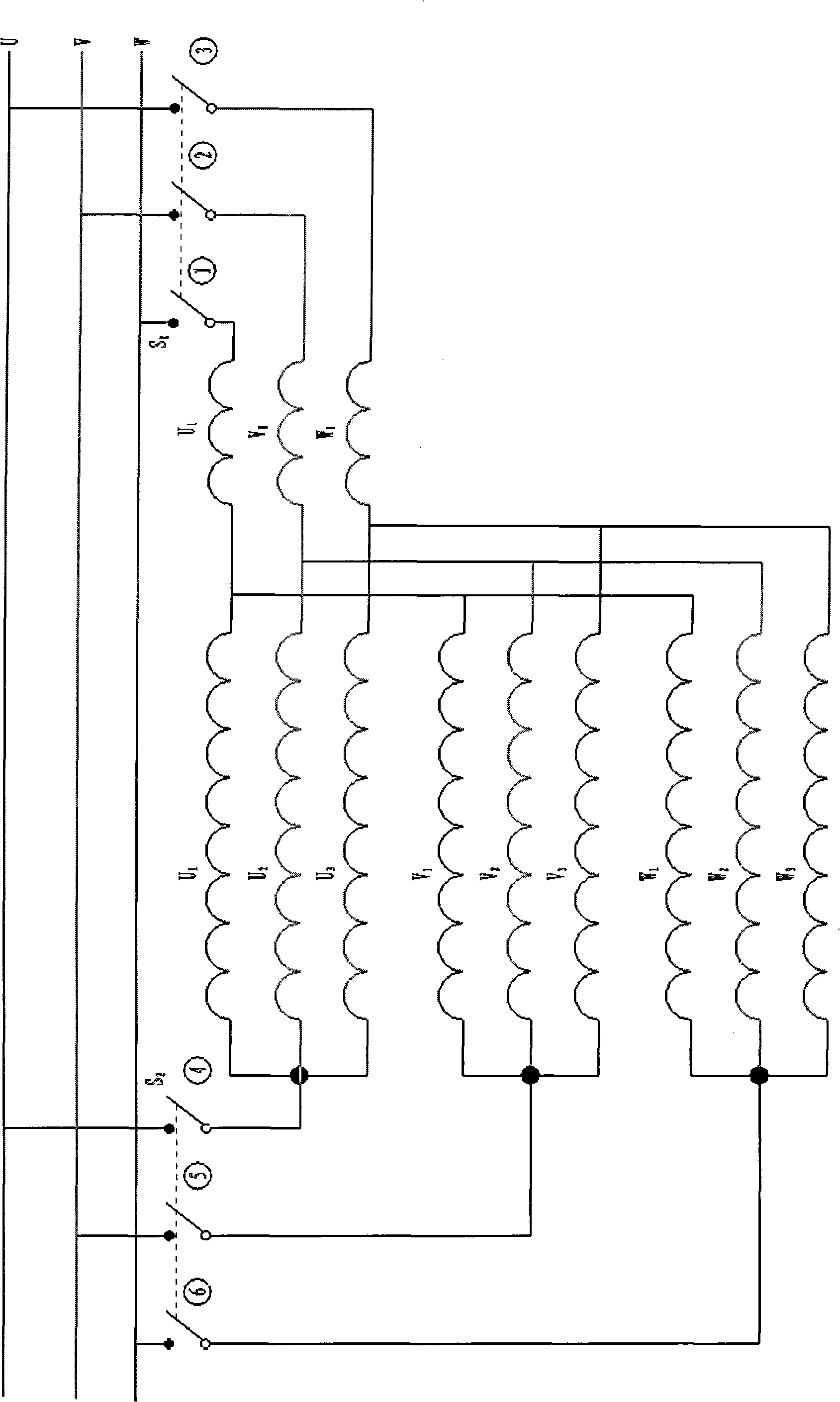

[0014] Figure 2 is the wiring diagram of the phase-changing and pole-changing windings of the two-speed motor 3Y+Y / 3Y connection in the prior art: the winding consists of 9 coils U 1 , V 1 , W 1 , U 2 , V 2 , W 2 , U 3 , V 3 , W 3 The "basic winding" and 3 coil groups u that make up the 3Y / 3Y connection 1 , v 1 、w 1 The "adjustment winding" composed of 6 lead wires are ④, ⑤, ⑥, ①, ②, ③ respectively, and the three-phase power switch S 1 with S 2 interlock, when S 2 2p when closing ④, ⑤, ⑥ connected to three-phase power supply 1 = Level 8, 3Y connection (at this time S 1 disconnected); when S 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com