Method for detecting adhesive force of metal layer on back of wafer

A backside metal and detection method technology, applied in semiconductor/solid-state device testing/measurement, etc., can solve the problems of inability to quantitatively measure the adhesion of the metal layer on the backside of the wafer, high detection cost, and expensive blue film price, etc., to achieve accurate measurement results Reliable, simple detection method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

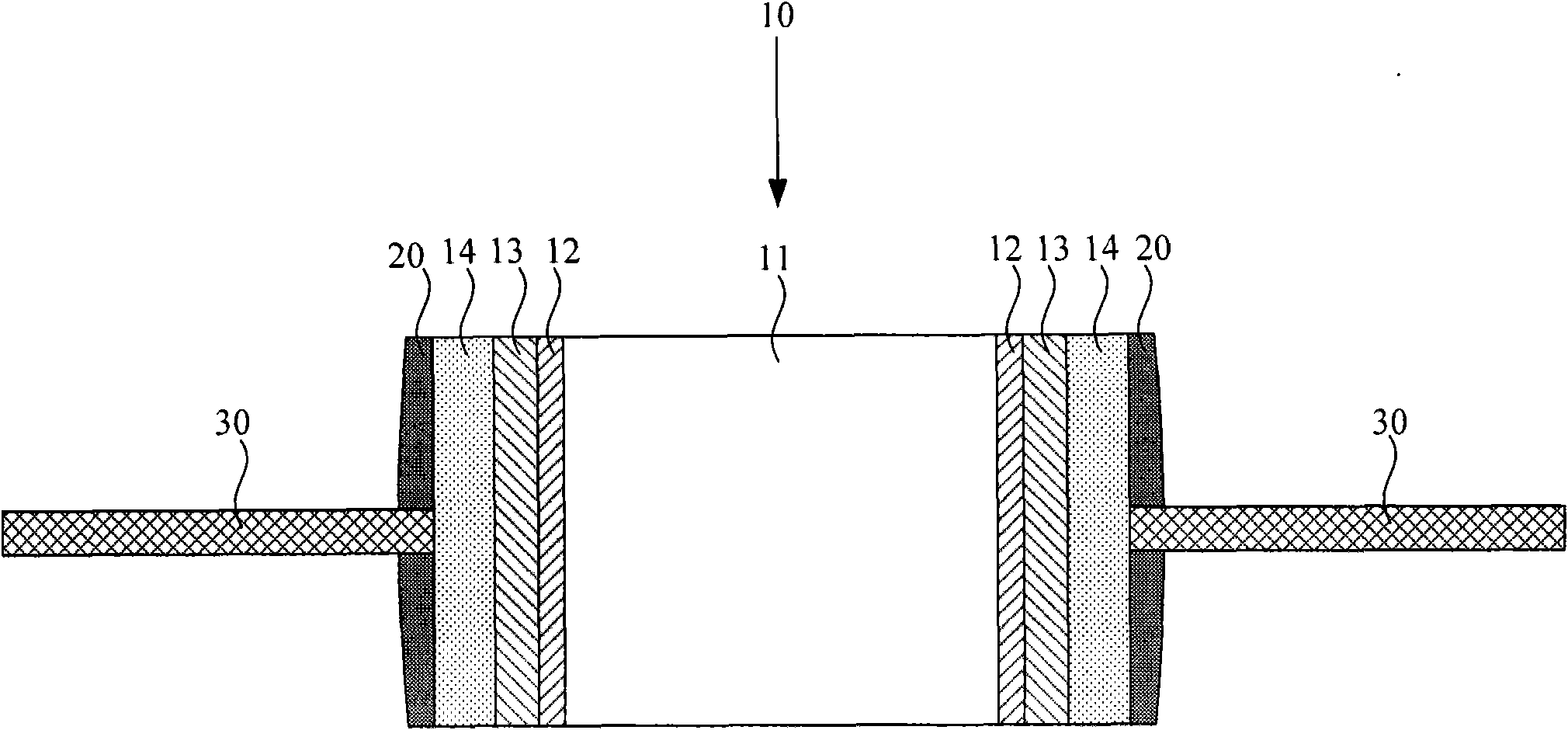

[0023] The following will combine Figure 1 ~ Figure 6 The method for detecting the adhesion of the metal layer on the back of the wafer of the present invention will be further described in detail.

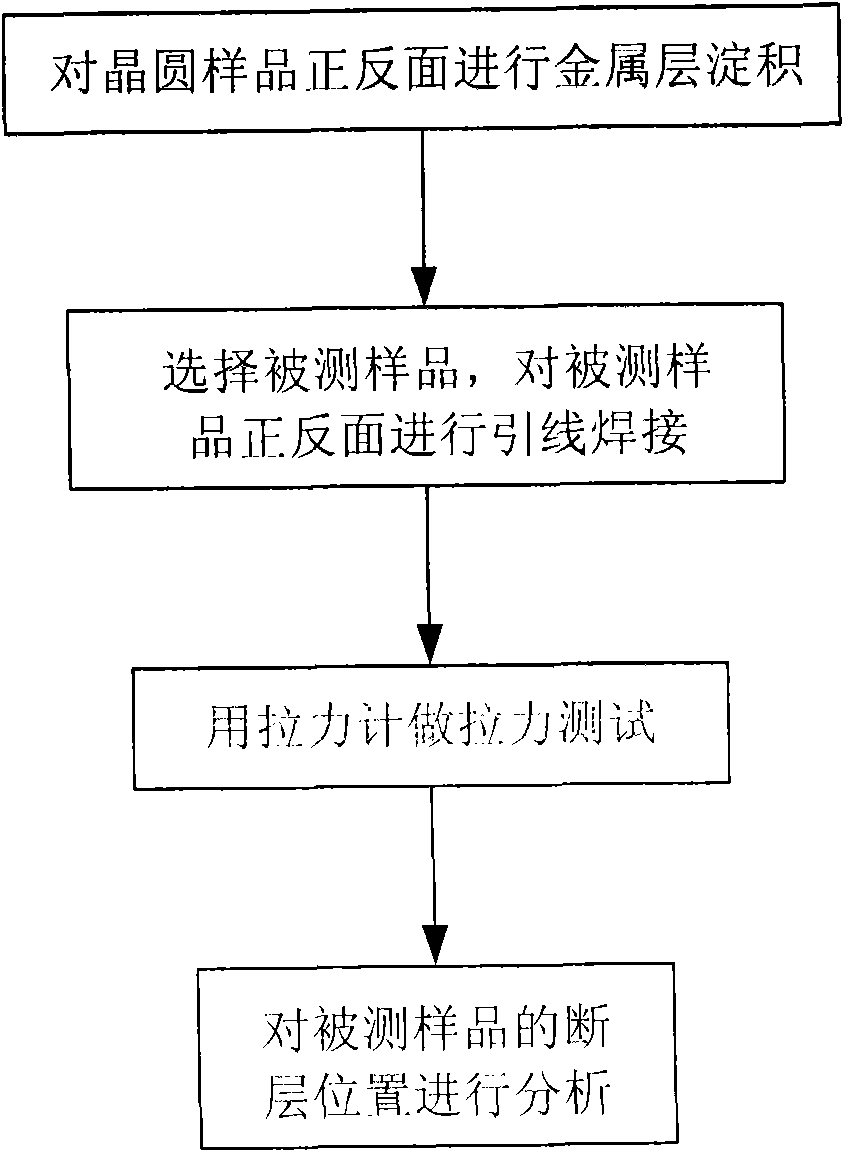

[0024] See figure 1 , The method for detecting adhesion of the metal layer on the back of the wafer of the present invention includes the following steps:

[0025] Step 1. Deposit a metal layer on the front and back of the wafer sample respectively;

[0026] Step 2: Choose core particles from the wafer samples with metal layers deposited on both the front and back sides as the tested sample, and solder leads on the front and back sides of the tested sample respectively;

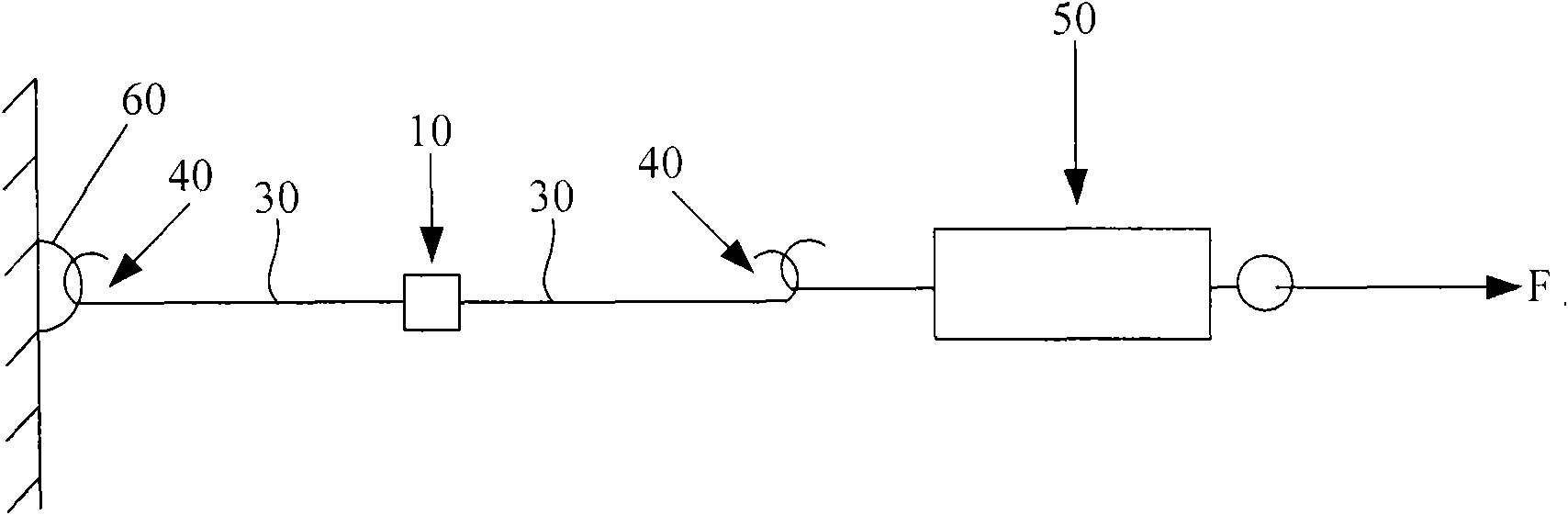

[0027] Step 3: Pull the lead on the back of the tested sample with a tension meter, and record the value of the tensile force before the tested sample is broken;

[0028] Step 4: Analyze the fault location of the tested sample.

[0029] An embodiment is now used to describe in detail the method for detecting the adhesion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com