Electronic lighter with inverted piezoelectric battery pack suite with no ignition lead and manufacturing method

A manufacturing method and technology of a battery pack, which are applied in the directions of combustion ignition, combustion method, igniter with fuel, etc., can solve the problems of low ignition reliability, short service life, and scrapped lighters, etc., achieve effective and reliable ignition, and improve assembly. The effect of speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

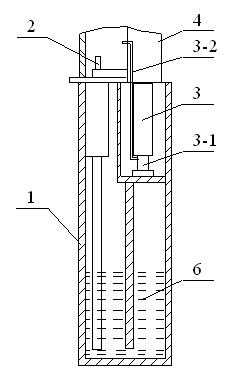

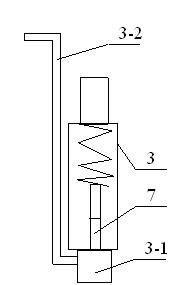

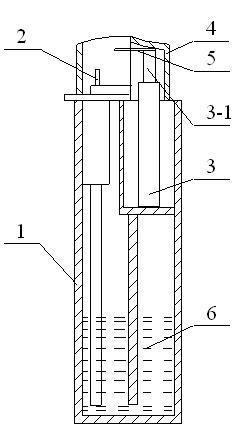

[0017] Embodiments of the present invention: a flip-chip electronic lighter without ignition wire voltage battery pack kit of the present invention is improved and manufactured on the basis of existing electronic lighters. The manufacturing method of the present invention includes using the existing The lighter housing 1, the jet valve assembly 2, the press battery set 3 and the press switch assembly 4 equipped with the liquid fuel 6 are assembled into an electronic lighter. When making the press battery set 3 in the existing way, the existing press battery The ignition wire 3-2 connected with its steel cap 3-1 of the group kit 3 is removed, and in the existing mode, the lighter housing 1, the jet valve assembly 2, the pressure battery pack kit 3 and the When pressing the switch assembly 4 to assemble the electronic lighter, the battery pack kit 3 witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com