Wave gear device

A technology of wave gear device and external gear, applied in the direction of gear transmission device, transmission device, belt/chain/gear, etc., can solve the problem that the fatigue strength of the tooth bottom of the flexible external gear is reduced, the rigidity is increased, and the load on the tooth surface cannot be obtained. distribution and other problems, to achieve the effect of increasing the fatigue strength of the tooth bottom, increasing the load capacity and improving the fatigue strength of the tooth bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

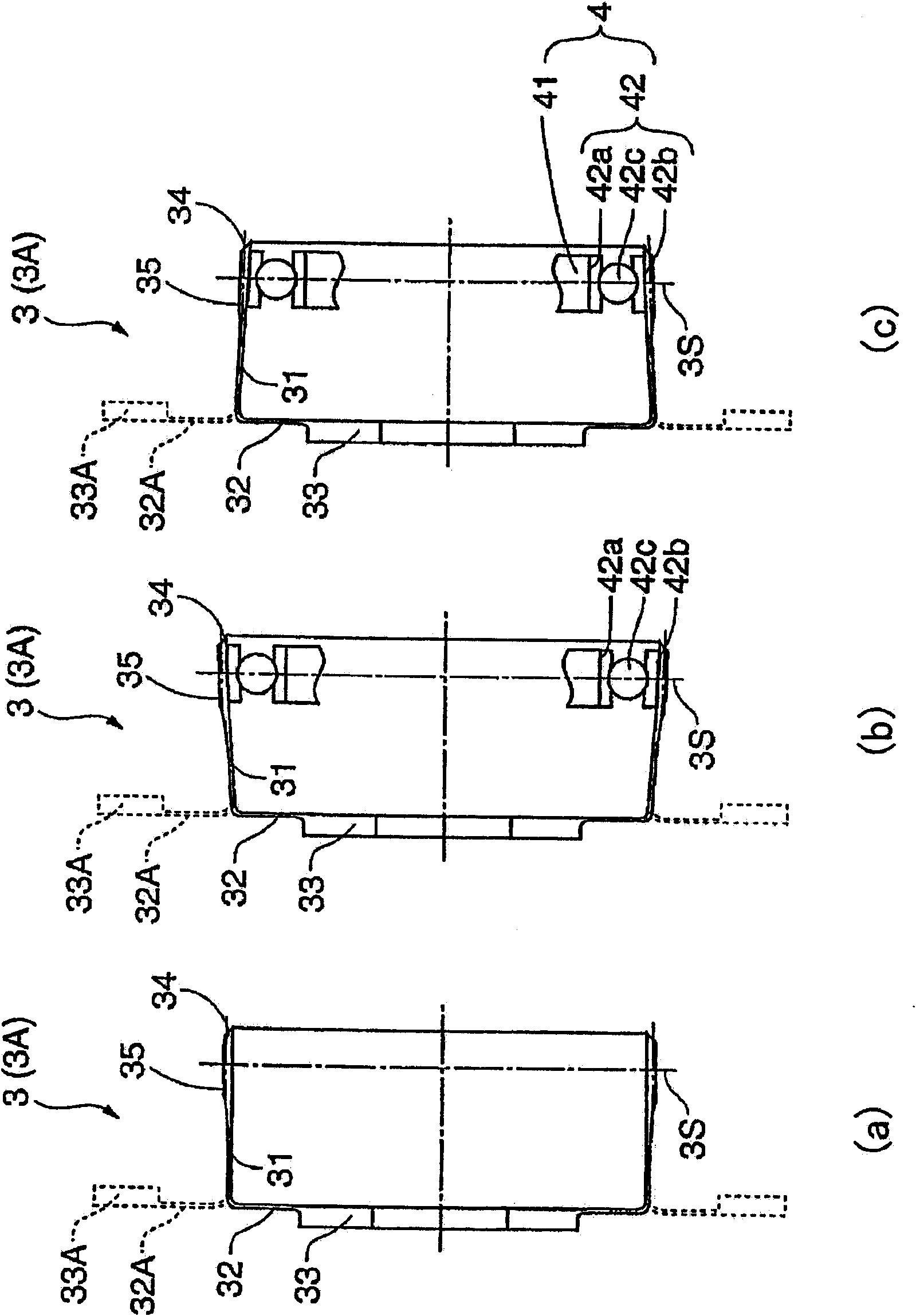

[0059] Hereinafter, embodiments of a cup-shaped or top hat-shaped wave gear device according to the present invention will be described with reference to the drawings. In addition, the overall structure of a cup-shaped or top hat-shaped wave gear device is the same as the general structure shown in FIGS. 1 and 2 .

[0060] (Flexible external gear rim wall thickness)

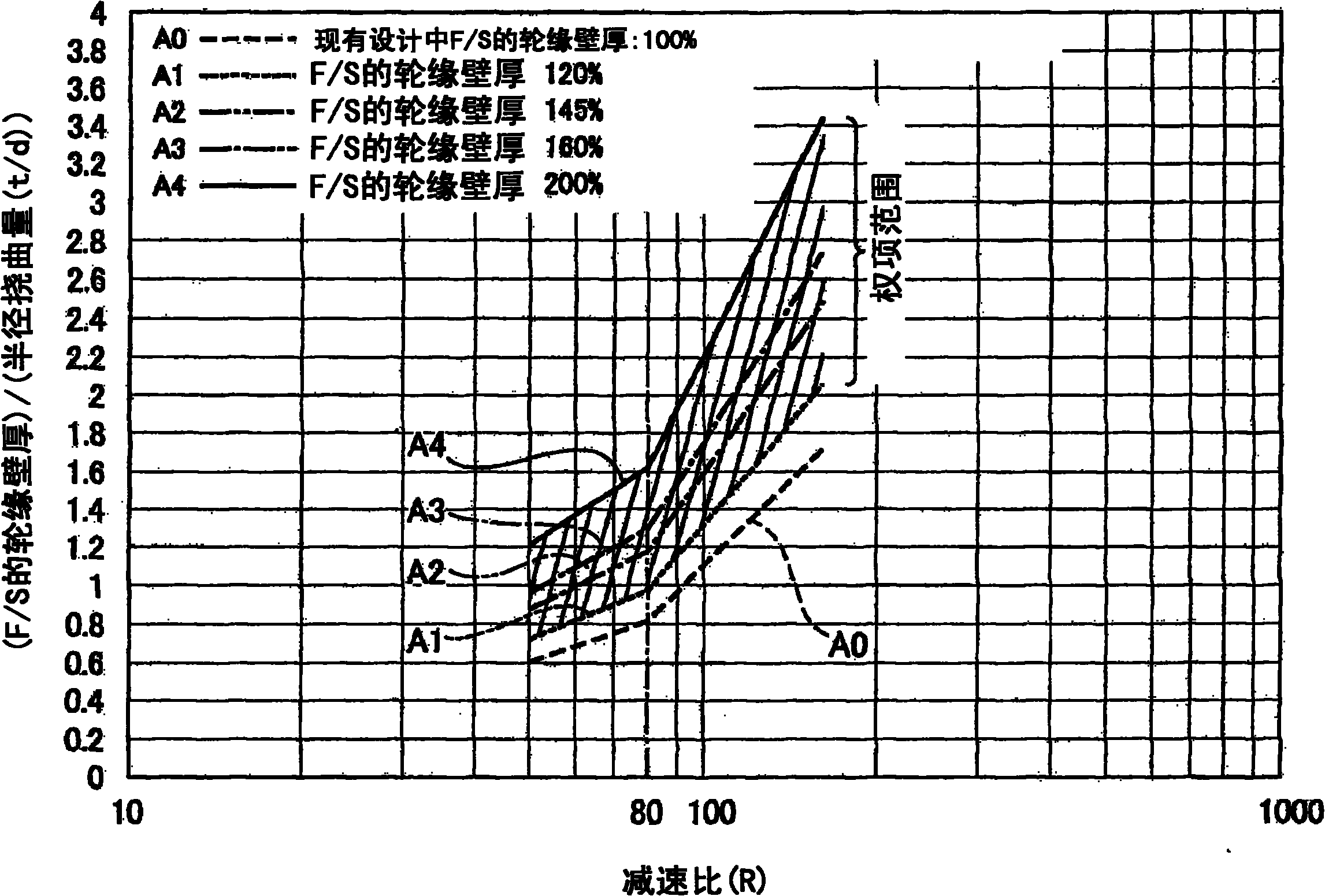

[0061] 3 is a conceptual diagram showing the rim thickness of a cup-shaped or top-hat-shaped flexible external gear in a cup-shaped or top-hat-shaped wave gear device. In this figure, the rim wall thickness is the thickness of the portion indicated by t. In addition, the radial deflection amount d of the flexible external gear 3 bent into an elliptical shape by the elliptical wave generator 4 is the axis perpendicular section set at an arbitrary position in the tooth line direction of the external teeth 35. Radius deflection at the location of the major axis of an ellipse bordering a neutral circle. If the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com