Method for calculating arc line in mechanical blade of impeller

A technology of impeller machinery and calculation method, which is applied to mechanical equipment, blade supporting elements, engine elements, etc., can solve problems such as long calculation time, inability to meet blade design and blade processing, and unable to obtain calculation results, saving calculation. time, guaranteed calculation convergence, and the effect of reducing the target area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

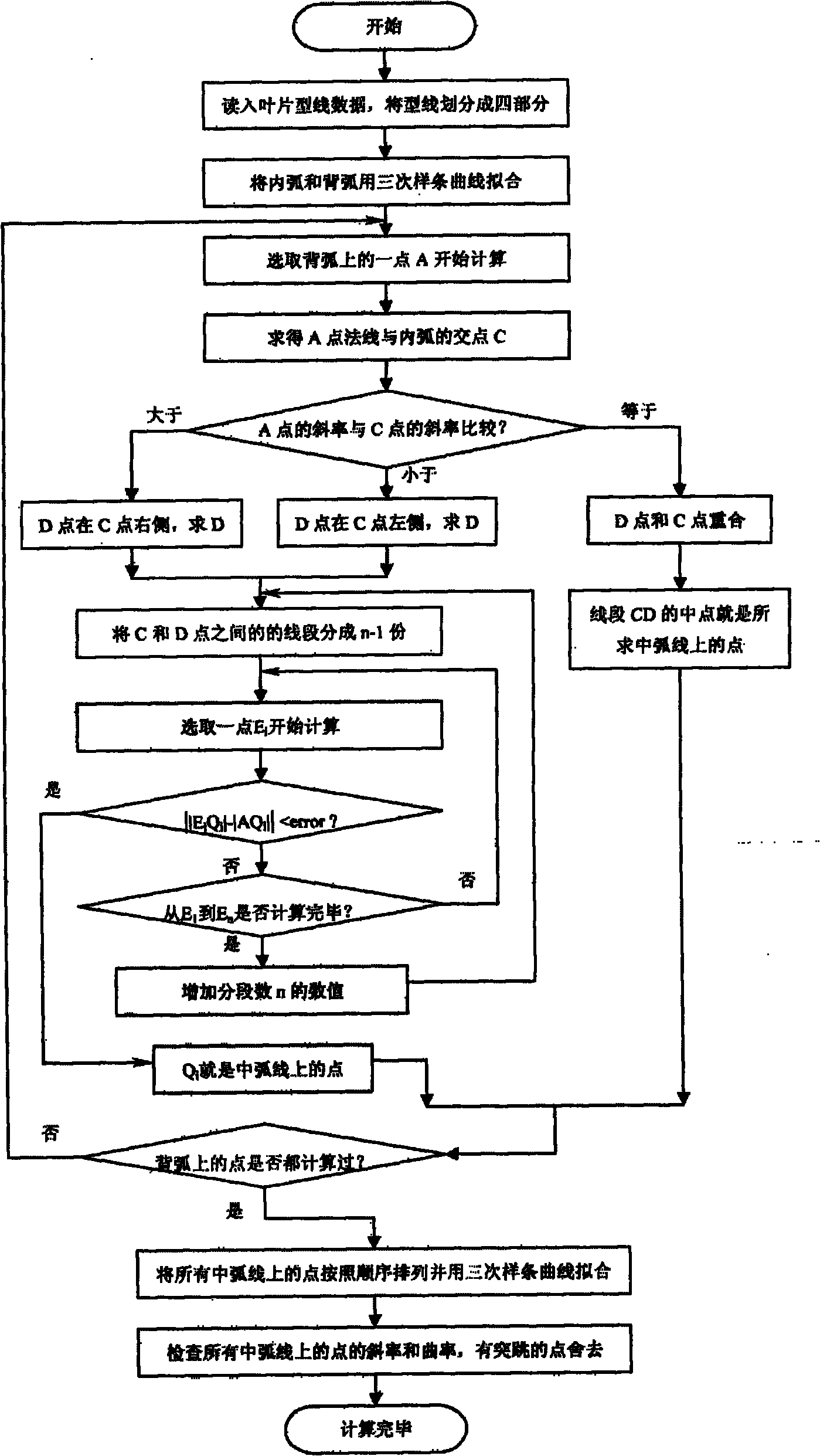

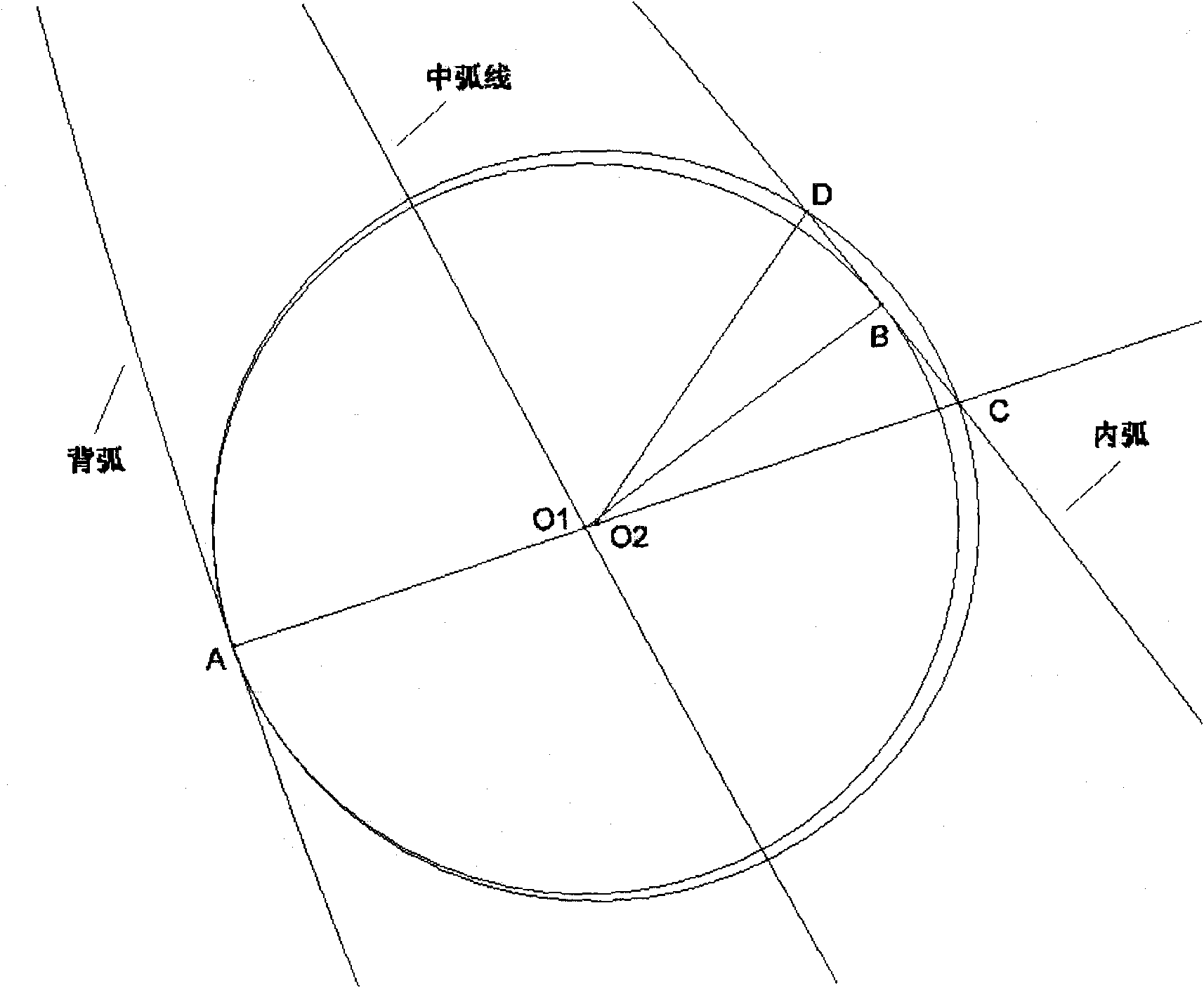

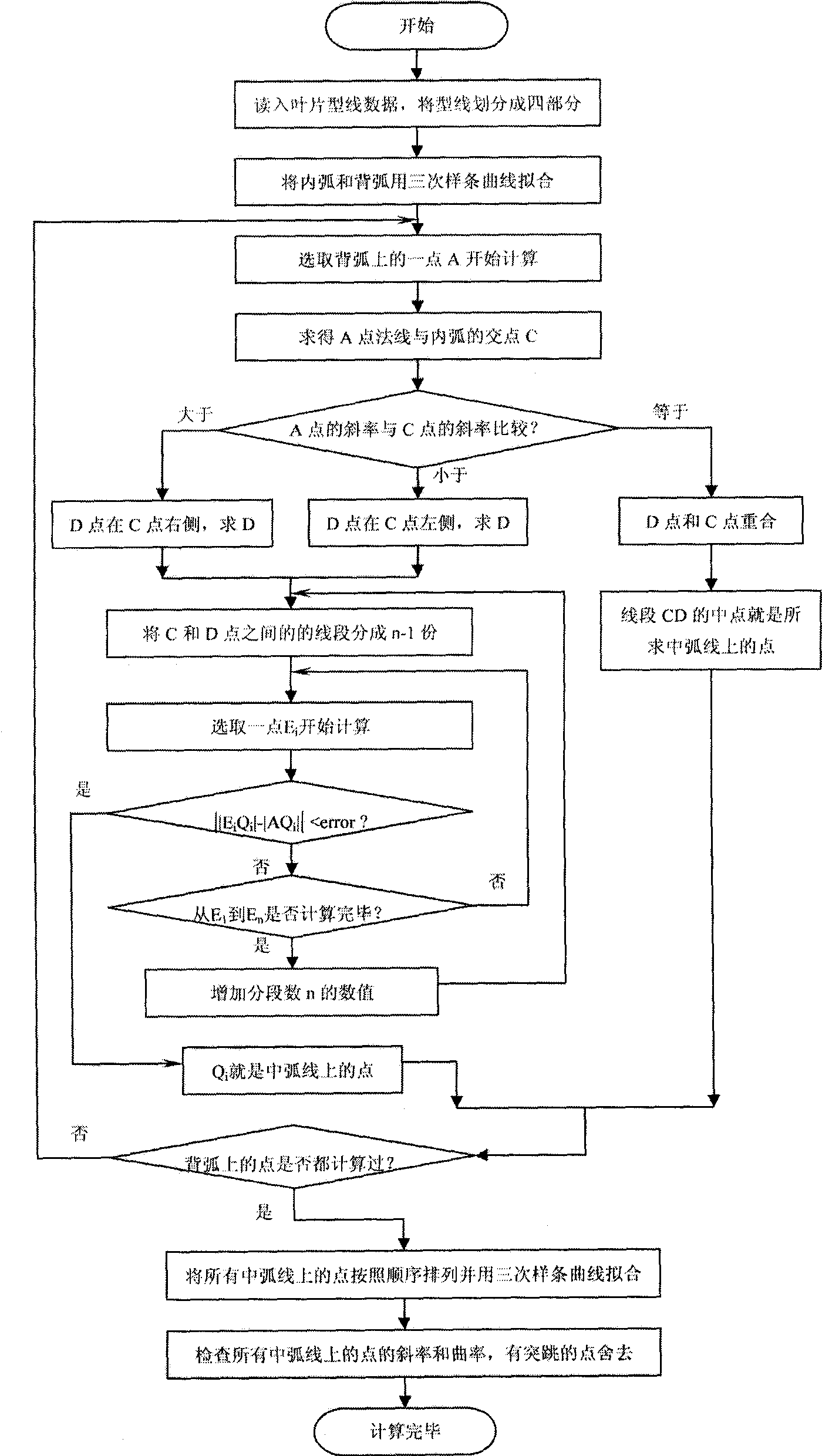

[0025] As shown in Figure 1, the middle arc of the blade should be located between the back arc and the inner arc of the blade, and a point on the middle arc can be selected as the center to make an inscribed circle that can be tangent to the back arc and the inner arc at the same time. Take a point A on the back arc and find the normal line of point A on the back arc. The normal line intersects the inner arc at point C. Take the line segment AC as the diameter to make a circle O2, and the other intersection point of the circle O2 and the inner arc For point D. Take point A as all points to make an inscribed circle O1, so that the inscribed circle O1 can be tangent to the back arc and the inner arc at the same time. The calculation shows that the center of the inscribed circle O1 must be on the line segment AC, and the inscribed circle O1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com