Glass door clamping rail

A technology for glass doors and tracks, which is applied in door/window accessories, wing leaf arrangement, wing leaf parts, etc. It can solve the problem of unstable clamping form, inability to firmly clamp glass 90, and reduce the overall quality of glass door assembly, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

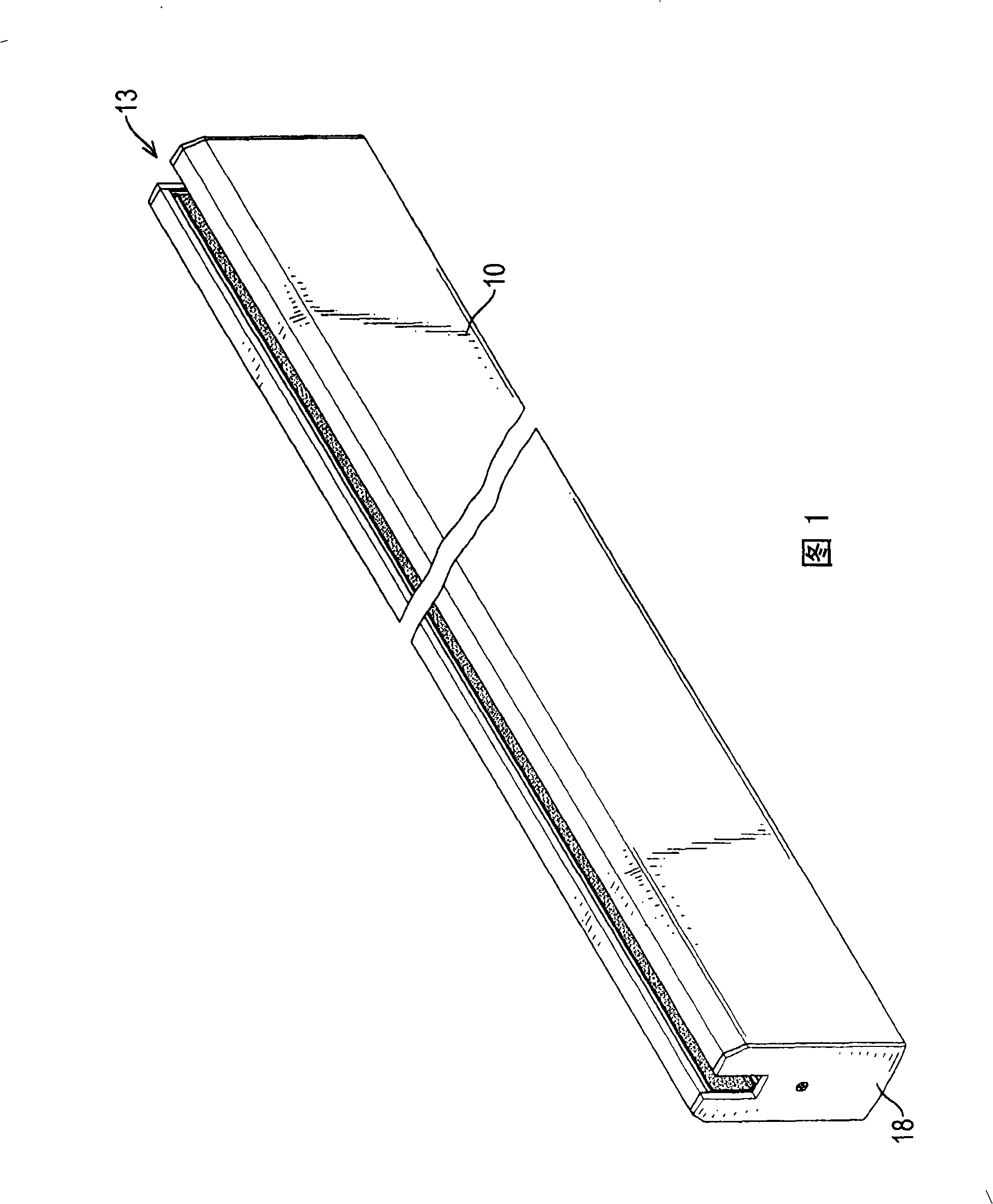

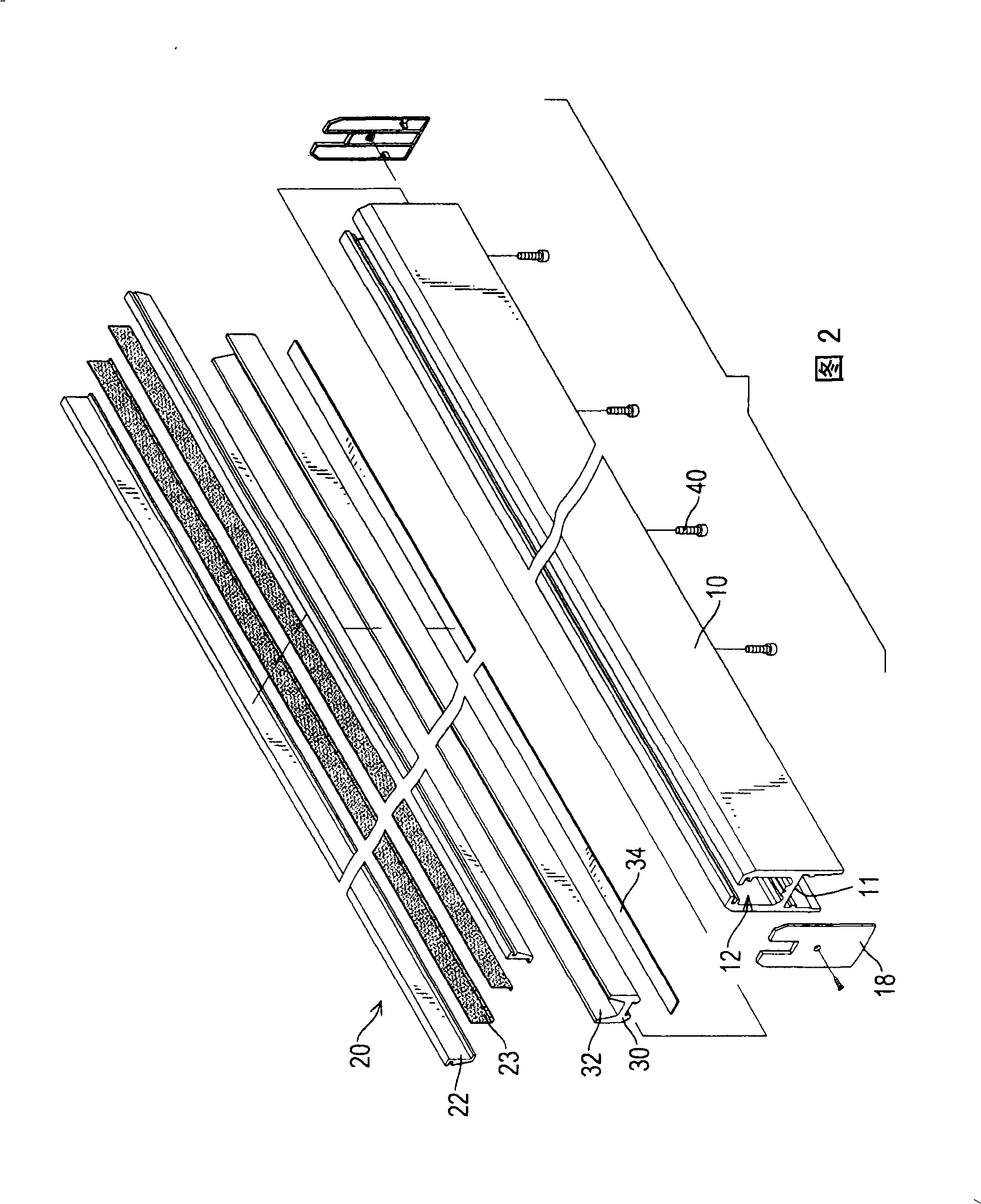

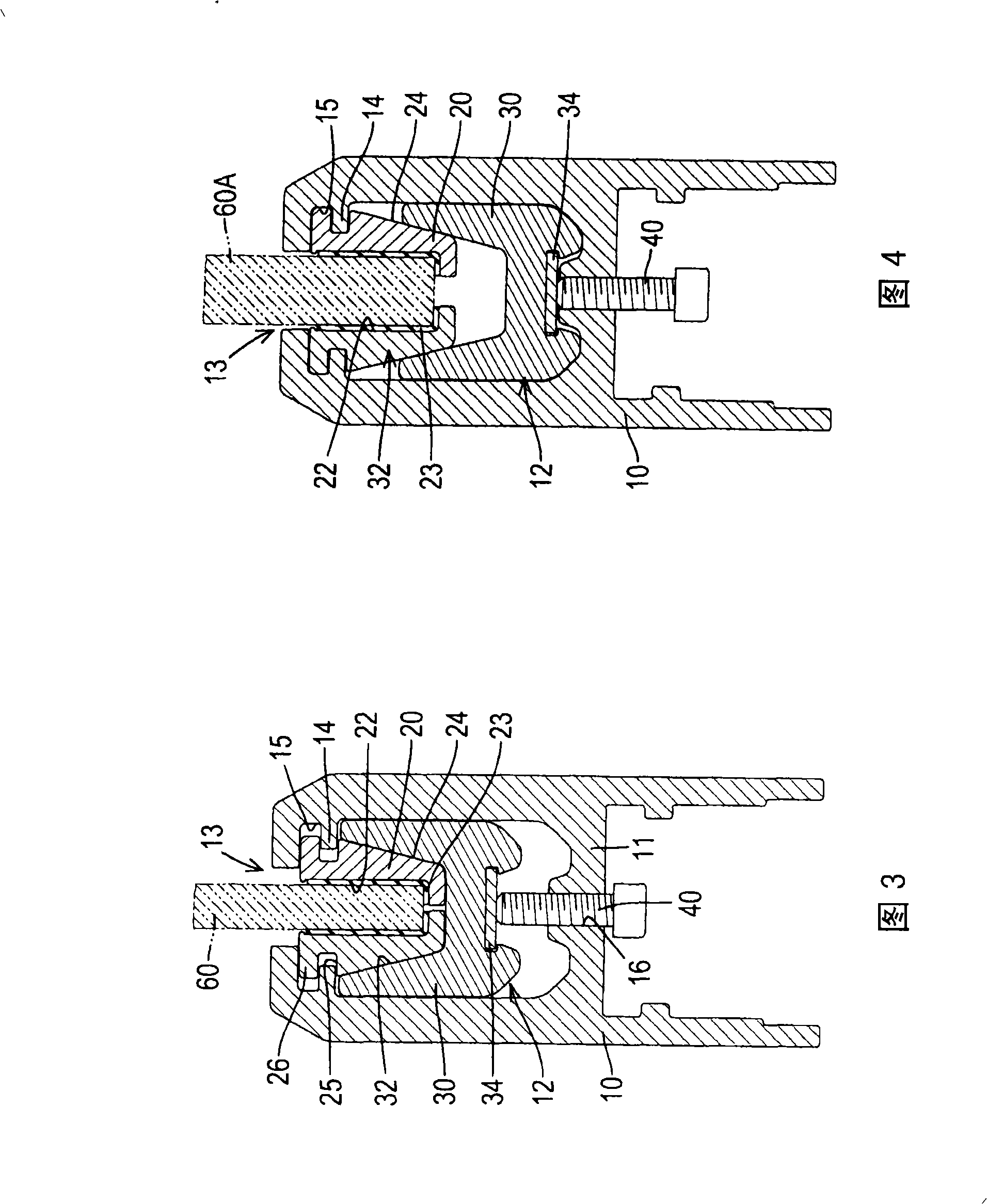

[0044] The present invention mainly provides a glass door clamping track, please refer to Figure 1 to Figure 3 , as can be seen from the figure, the clamping track of the present invention mainly includes an elongated track body 10, the track body 10 is generally H-shaped cross-section, and a spacer rib 11 is formed in the middle of the track body 10, and on the track Body 10 is positioned at the side of spacer rib 11 to form a clamping road 12, and an opening 13 that communicates with clamping road 12 is formed on an end surface of track body 10, and two inner edges near opening 13 places of track body 10 Contrasting guide ribs 14 are protrudingly formed on the surface, and a guide groove 15 is formed between the two guide ribs 14 and the edge of the opening 13 of the track body 10 .

[0045] In addition, two elongated clamping bars 20 are arranged in the clamping channel 12 of the track body 10. The two clamping bars 20 can be arranged in the clamping channel 12 close to or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com