Combined-type spoke

A composite, spoke technology, applied in the field of spokes, can solve the problems of insufficient performance, high fracture rate, heavy weight, etc., and achieve the effect of reducing weight, reducing weight and preventing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

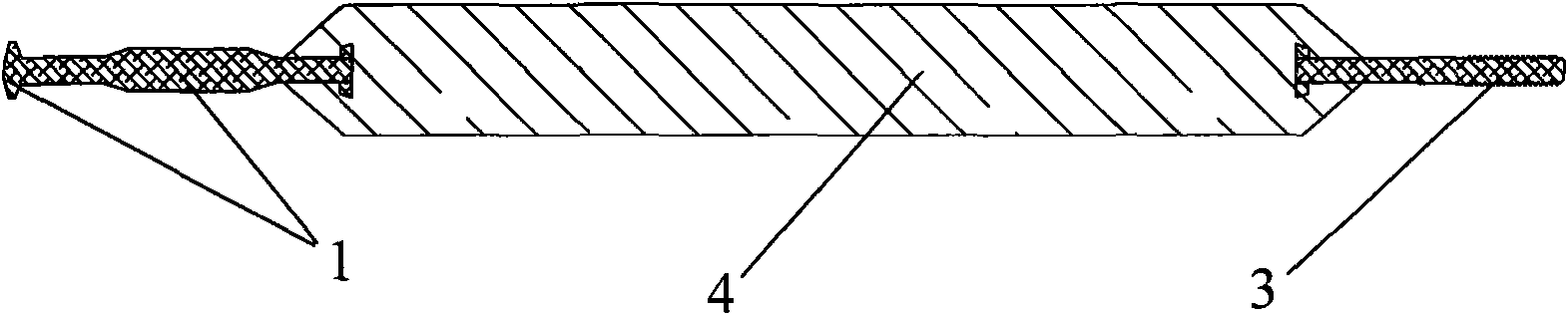

[0022] see image 3 , a composite spoke, including an elbow 1, a main body 2 and a screw thread 3, such as image 3 a and 3b, the outer surface of the main body 2 is covered with a carbon fiber layer 4 .

Embodiment 2

[0024] see Figure 4 , Figure 5 , a composite spoke, comprising an elbow 1, a main body 2 and a screw thread 3, the outer surface of the main body 2 is covered with a carbon fiber layer 4.

[0025] Such as Figure 5 b, the cross-sectional shape of the main body 2 (the cross-section is a plane perpendicular to the paper and the length direction of the spokes) is a closed figure composed of two horizontal parallel straight lines up and down and two convex arcs on the left and right.

[0026] Such as Figure 5 a, the maximum diameter of the main body part 2 is larger than the diameter of the joint between the elbow part 1 and the main body part 2, and the connection between the main part 2 and the elbow part 1 forms a trapezoidal connection section in front view, that is, the transition between the diameter and the cross-sectional shape part. The maximum diameter of the main body part 2 is larger than the diameter of the connection position between the screw thread part 3 an...

Embodiment 3

[0028] Such as Figure 6 , Figure 7 , a composite spoke, including an elbow 1, a main body 2 and a screw thread 3, such as Figure 6 b, the cross-section of the main body (this cross-section is a plane perpendicular to the paper and perpendicular to the length direction of the spokes) is elliptical, the main body 2 has a plurality of small holes 21, and the outer surface of the main body 2 is covered with a carbon fiber layer 4. The small hole 21 provided in the main body part 2 can further reduce the weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com