Automatic picking control method and system of plate products

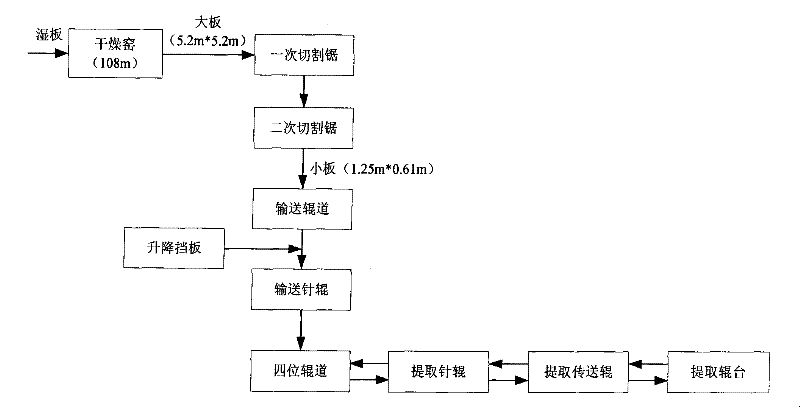

An automatic extraction and control system technology, applied in the direction of conveyor control devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of small boards and random boards, and achieve the effect of flexible and reliable system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

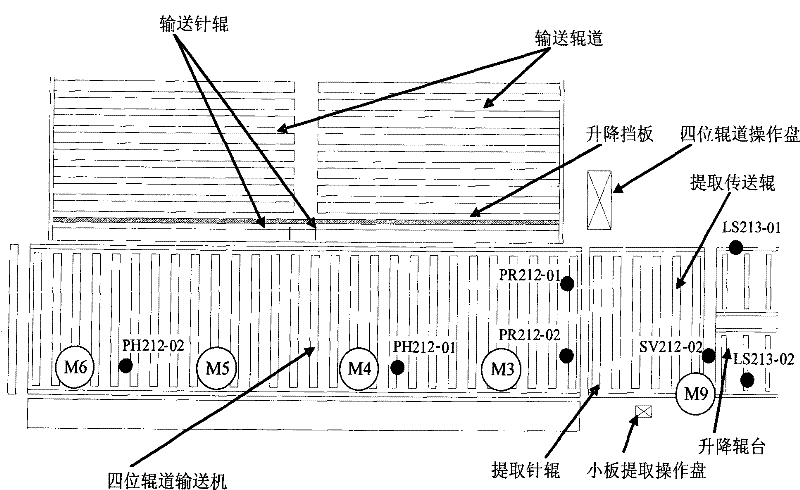

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

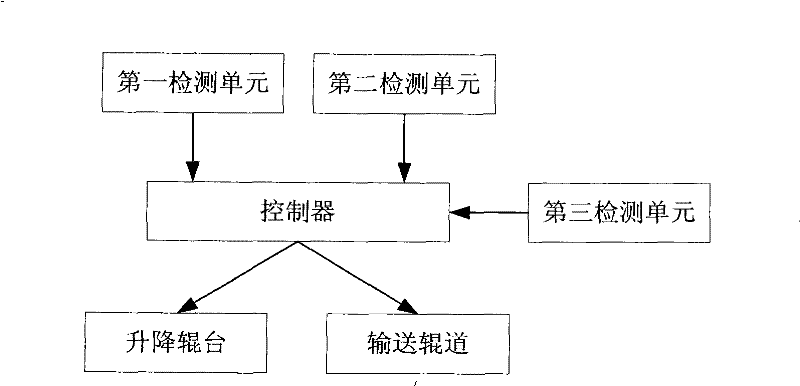

[0031] Such as figure 2 As shown, the control system includes a conveying roller table, a lifting roller table, a first detection unit, a second detection unit and a control unit. The conveying roller table and the lifting roller table are placed continuously so that the plate can be transported from the conveying roller table to the lifting roller on stage, where:

[0032] The conveying roller table is used to convey the plate to the lifting roller table;

[0033] The elevating roller table is used to ascend or descend according to the command of the control unit;

[0034] The first detection unit is located on the conveying roller table, and is used to detect whether there is a board on the conveying roller table, and if a board is detected, send a signal to the control unit;

[0035] The second detection unit is used to detect whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com