Precise numerically-controlled invertible vertical honing equipment

A precision numerical control and honing technology, which is applied in the direction of honing machine tools, metal processing equipment, manufacturing tools, etc., can solve problems such as complex procedures, affecting processing efficiency, and affecting the normal use of parts, and achieve the effect of precise processing and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

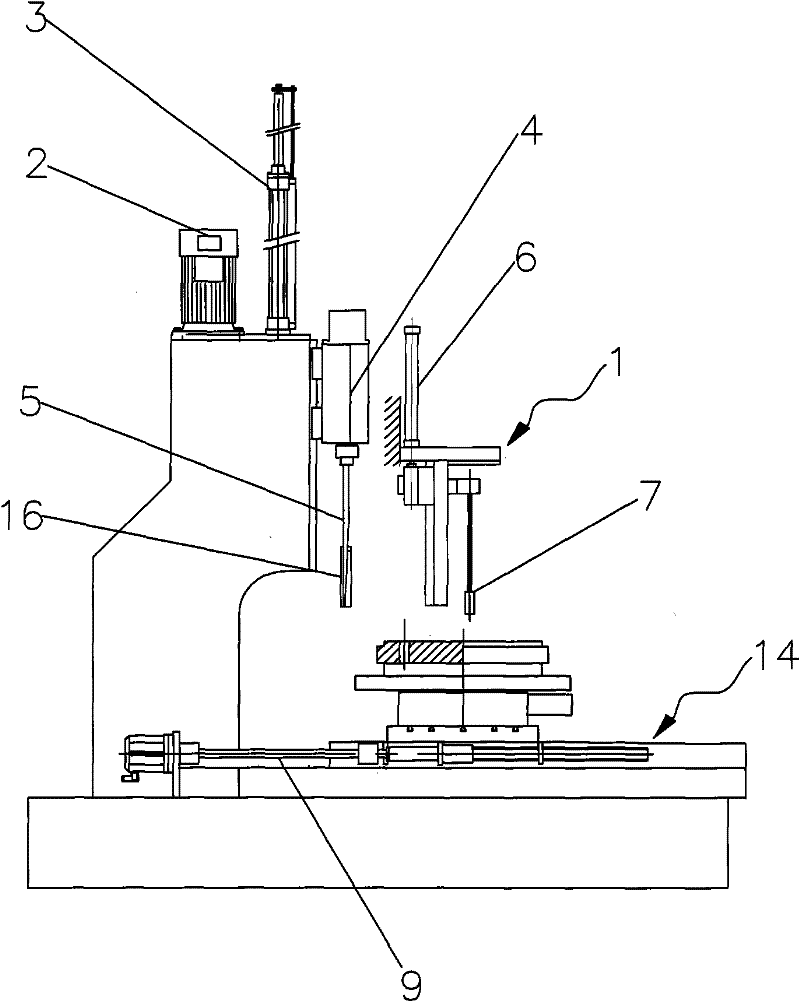

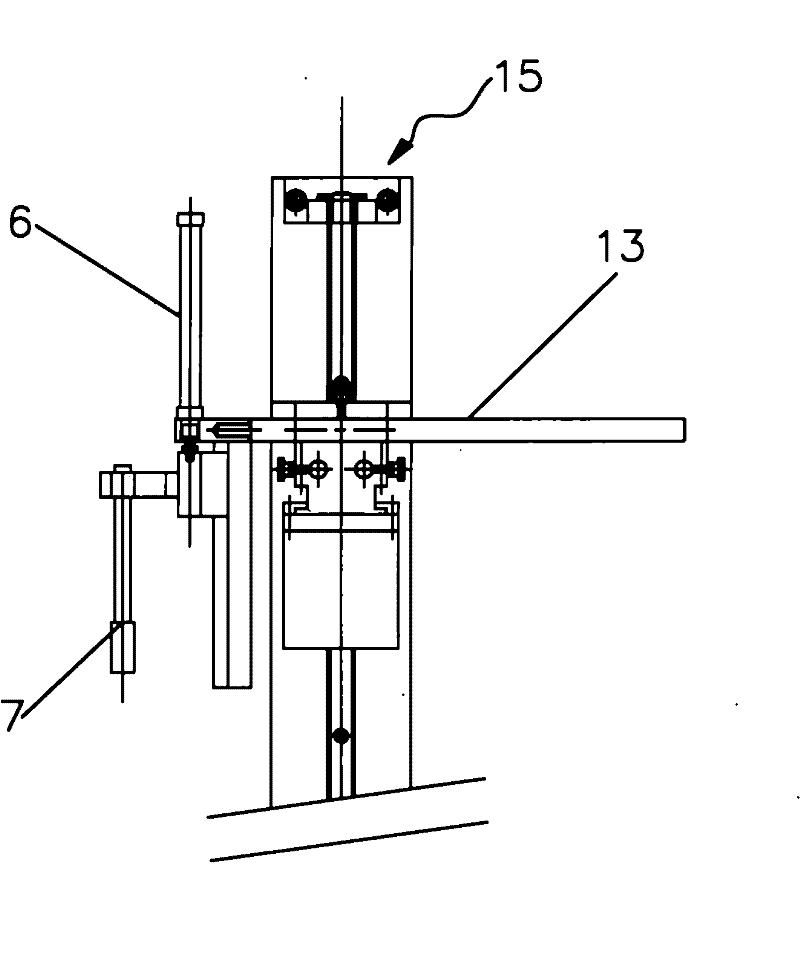

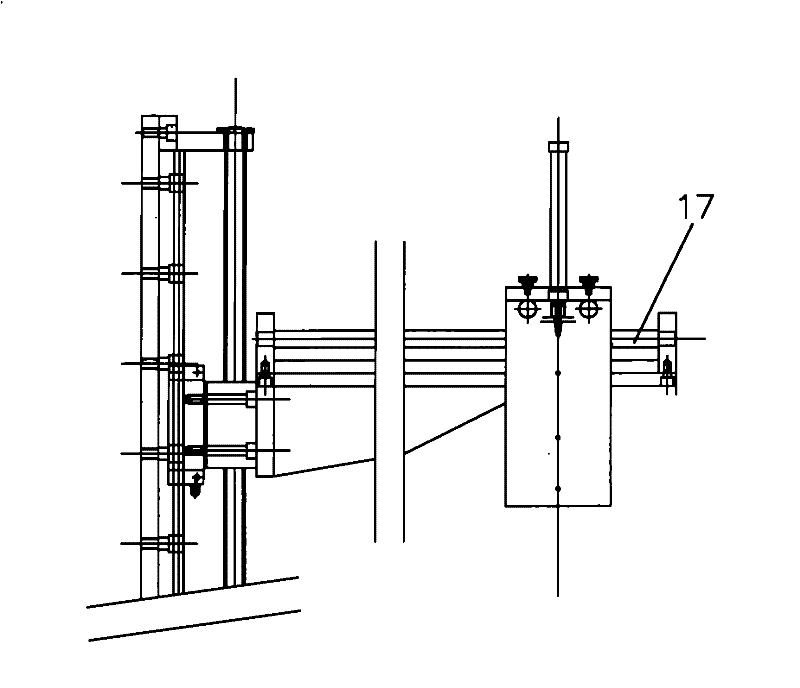

[0022] Refer to attached figure 1 As shown: the honing equipment includes at least one honing head unit, a rotary drive mechanism that controls the honing head unit to perform rotary motion, a stroke drive mechanism that controls the honing head unit to perform reciprocating stroke motion, and a detection motion for detecting the parameters of the honed hole Device 1, a control unit for controlling each processing unit, and a table device 14 for placing parts to be processed.

[0023] The rotary drive mechanism and the stroke drive mechanism are connected with the honing head unit; the workbench device 14 can be movably adjusted to match the position of the honing hole of the part to be processed; the detection motion device 1 is also arranged above the workbench device 14 . Under the control of the control unit, after the honing head unit comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com