Baking oven device of matrix (copper foil or aluminum foil) suspension type coating machine

A coating machine, suspension technology, applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of substrate scars, wrinkles, affecting product quality, etc., to solve friction problems, speed up coating Cloth speed, the effect of increasing the length of the oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

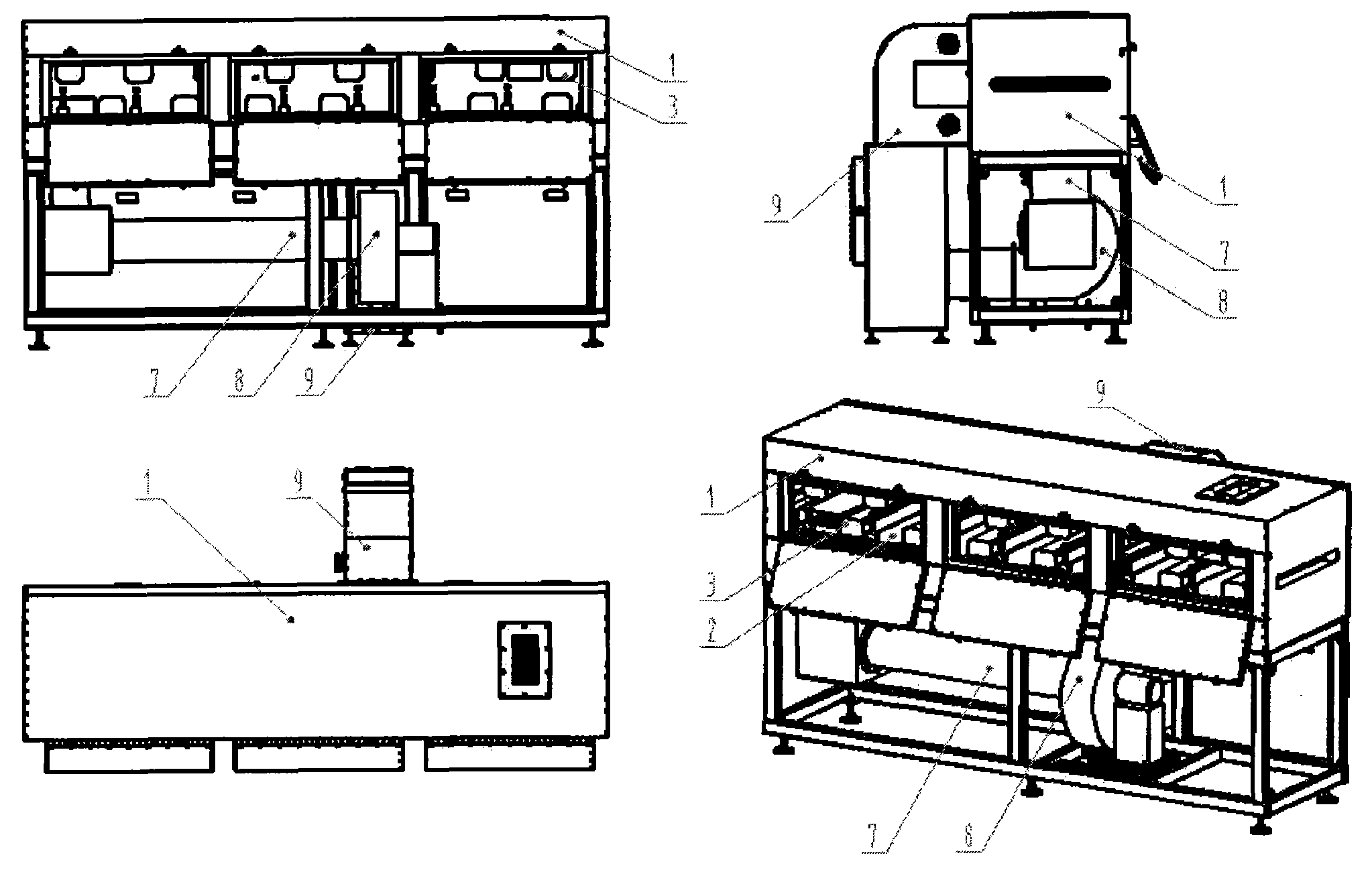

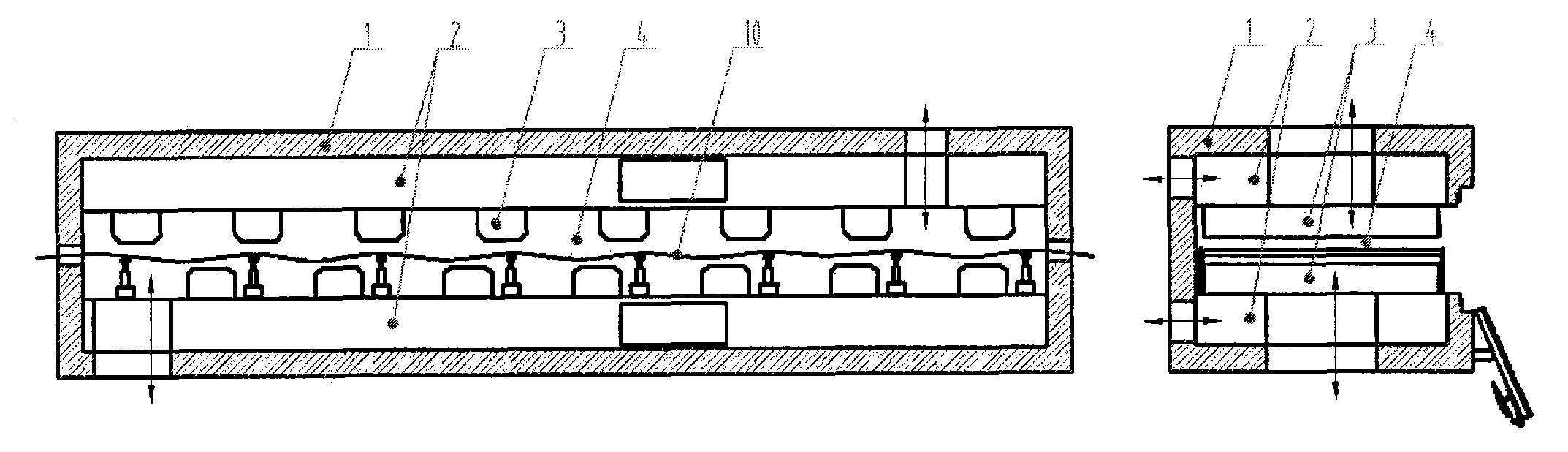

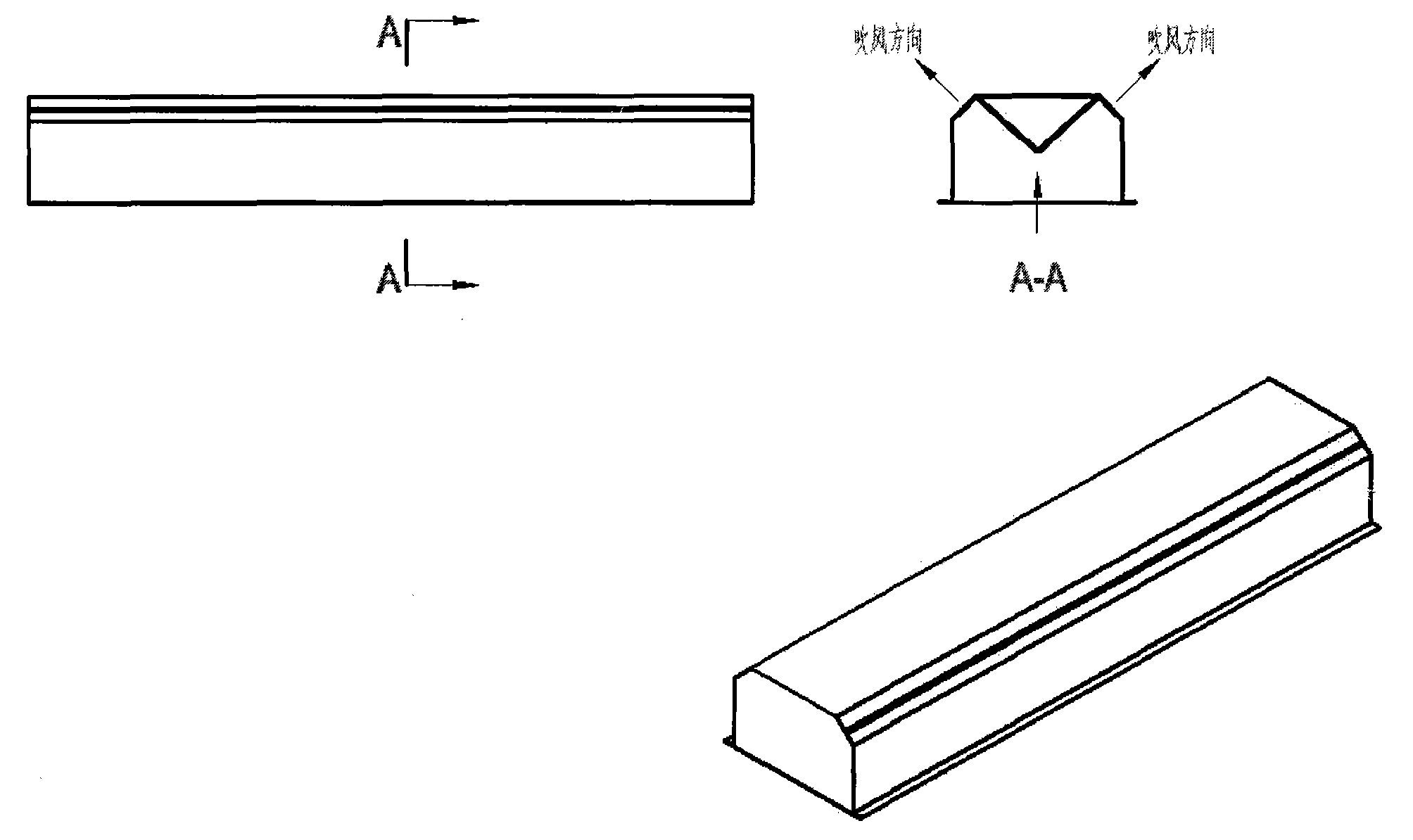

[0021] As shown in Figures 4, 5, 6, and 7: the substrate (aluminum foil or copper foil) suspension coating machine oven device of the present invention includes an oven main body 1 (oven inner and outer tanks, oven door, oven frame), an air inlet chamber 2 , Improved air nozzle 3, drying chamber 4, exhaust chamber 5, circulating air chamber 6, circulating air duct 7, blower 8, heating device 9, etc. The interior of the main body 1 of the oven is divided into upper and lower two air inlet chambers 2, and the improved air nozzles 3 are respectively installed on the two air inlet chambers 2. The inner cavity of the air nozzle 3 is connected with the air inlet chamber 2, and the two Between the air chamber 2 is the drying chamber 4, the cavity between the upper air inlet chamber 2 and the oven main body 1 is the exhaust chamber 5, and the cavity between the lower air inlet chamber 2 and the oven main body 1 is the circulation air chamber 6, and the circulation The air duct 7 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com