Method and device for controlling precise measurement of hydrogen sulfide pulsation injecting liquid through pressure degenerative feedbacks

A hydrogen peroxide, negative feedback technology, applied in water supply devices, sanitary equipment for toilets, buildings, etc., can solve the problems of uncontrollable hydrogen peroxide dosage, harm, user injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

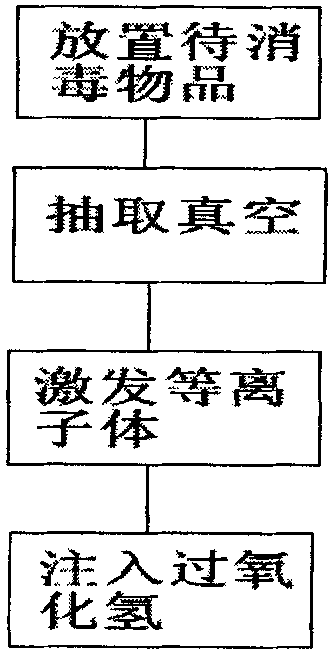

Method used

Image

Examples

Embodiment Construction

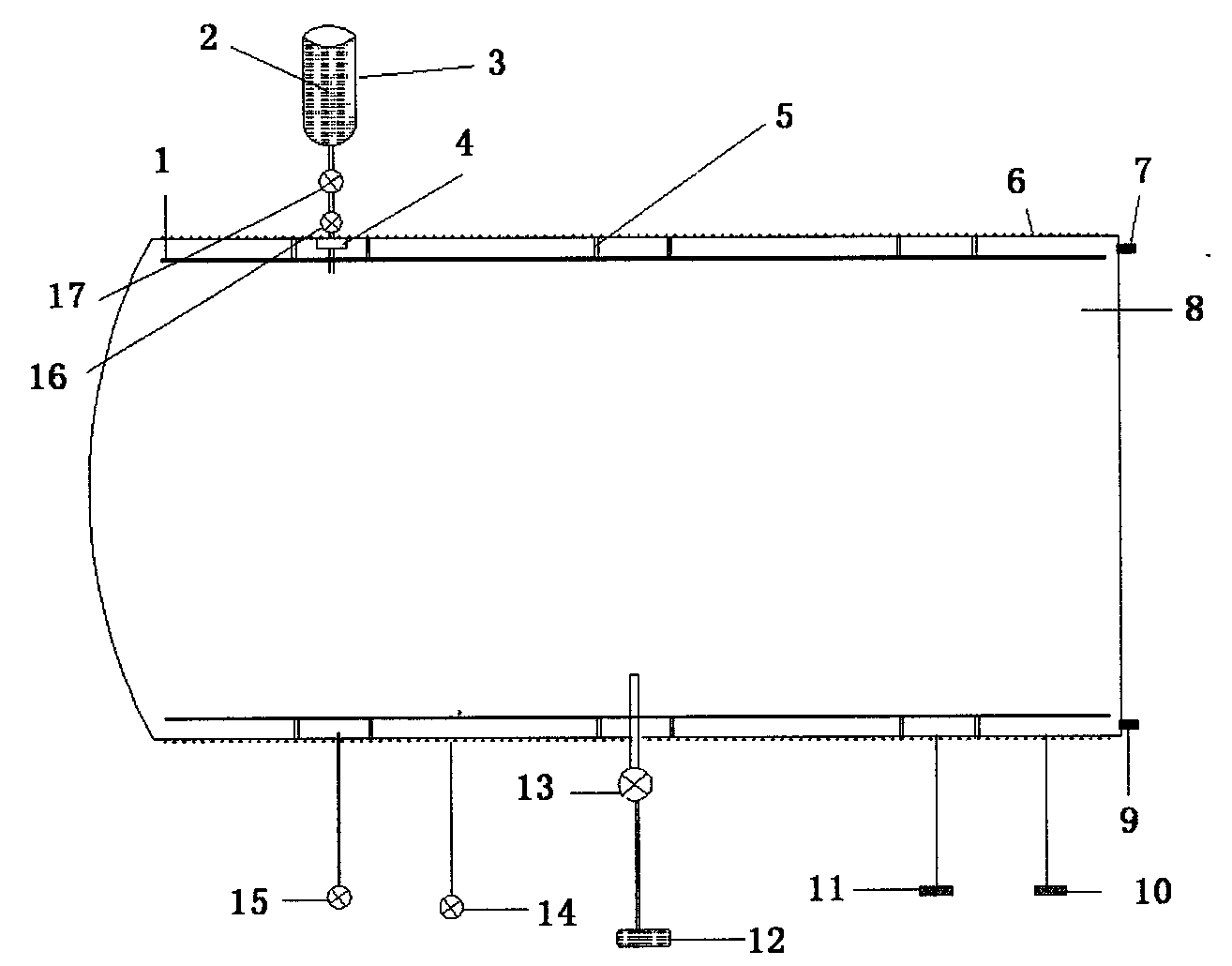

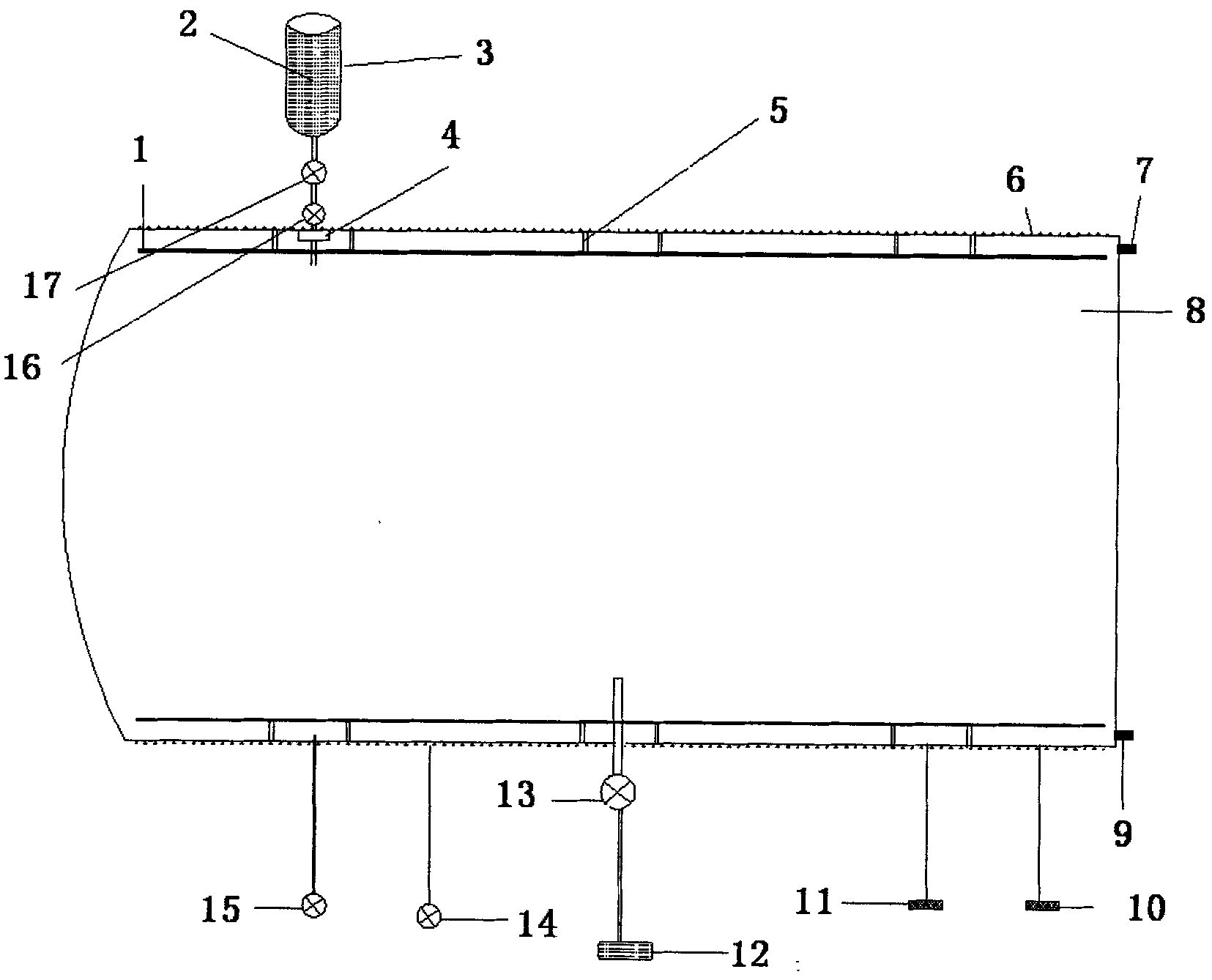

[0021] Fig. 1 is a schematic diagram of a cross-sectional structure of a plasma sterilizer. By describing the structure of the sterilizer, the working principle and specific use method of the sterilizer are illustrated.

[0022] The main structure of the plasma sterilizer is a sterilization chamber 8, which is a cylindrical or rectangular structure. When using the plasma sterilization chamber for sterilization, the articles to be sterilized are placed in the sterilization chamber 8 , the top and bottom of the sterilization chamber 8 are provided with a mesh antenna 1 for exciting plasma, and the connection mesh antenna at the top is fixed on the sterilization chamber 8 through an insulating bracket 5, wherein the mesh The mesh antenna 1 can also be arranged on the opposite inner wall of the sterilization chamber 8 through an insulating support. Plasma can be generated by applying power to the mesh antenna 1 for excitation. The sterilization chamber 8 is connected with multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com