Processing apparatus

A technology of processing equipment and processing department, applied in clothing, underwear, baby underwear, etc., to achieve the effect of restraining tension fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

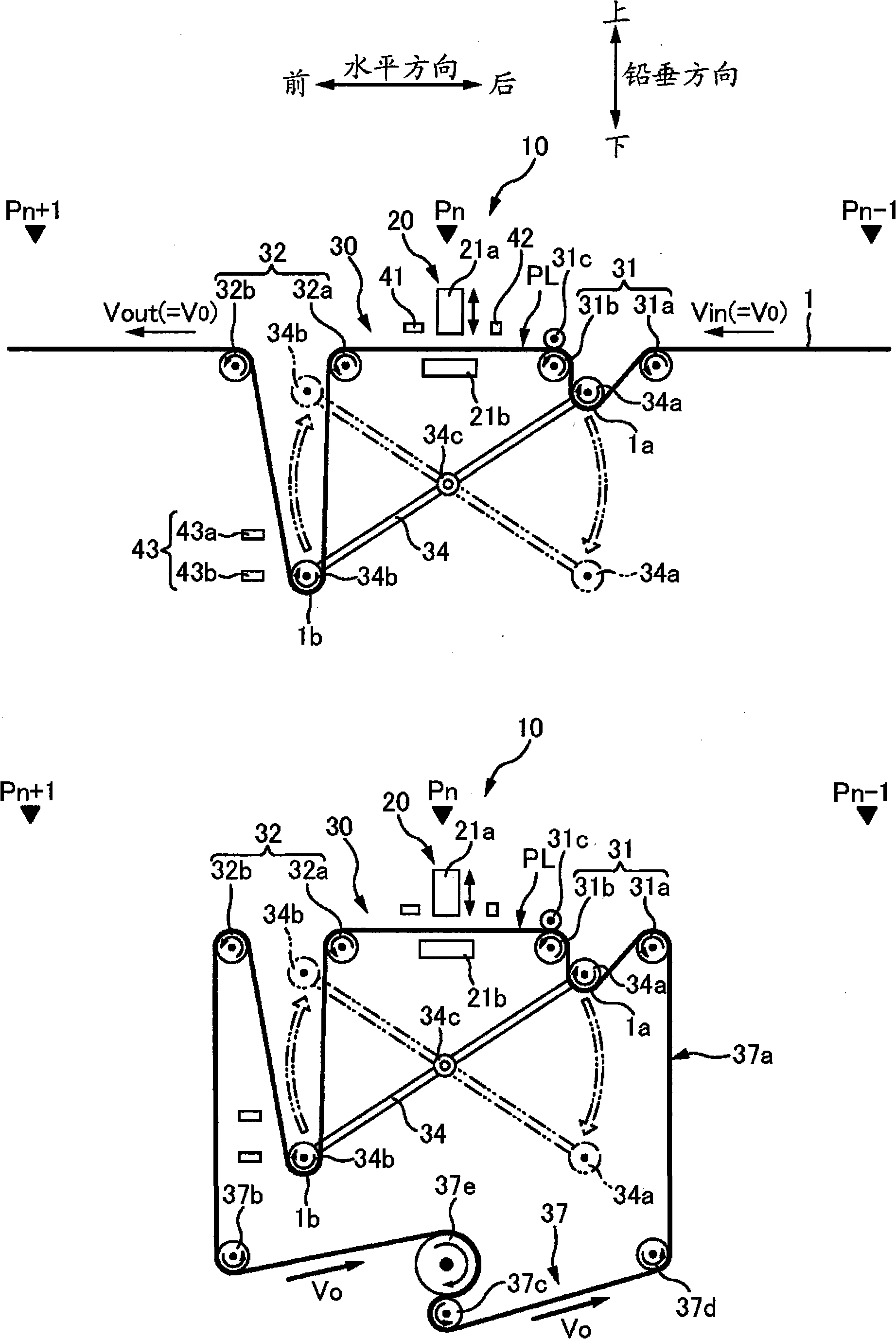

[0117] 4A and 4B are side views of the processing apparatus 10 according to the first embodiment. Note that, for simplicity of the drawing, FIG. 4A shows the processing apparatus 10 without the tension fluctuation suppressing mechanism 37 as a component of the processing apparatus 10, and conversely, FIG. 4B shows the tension fluctuation suppressing mechanism 37 with but without There is a processing device for a strip-shaped workpiece 1 .

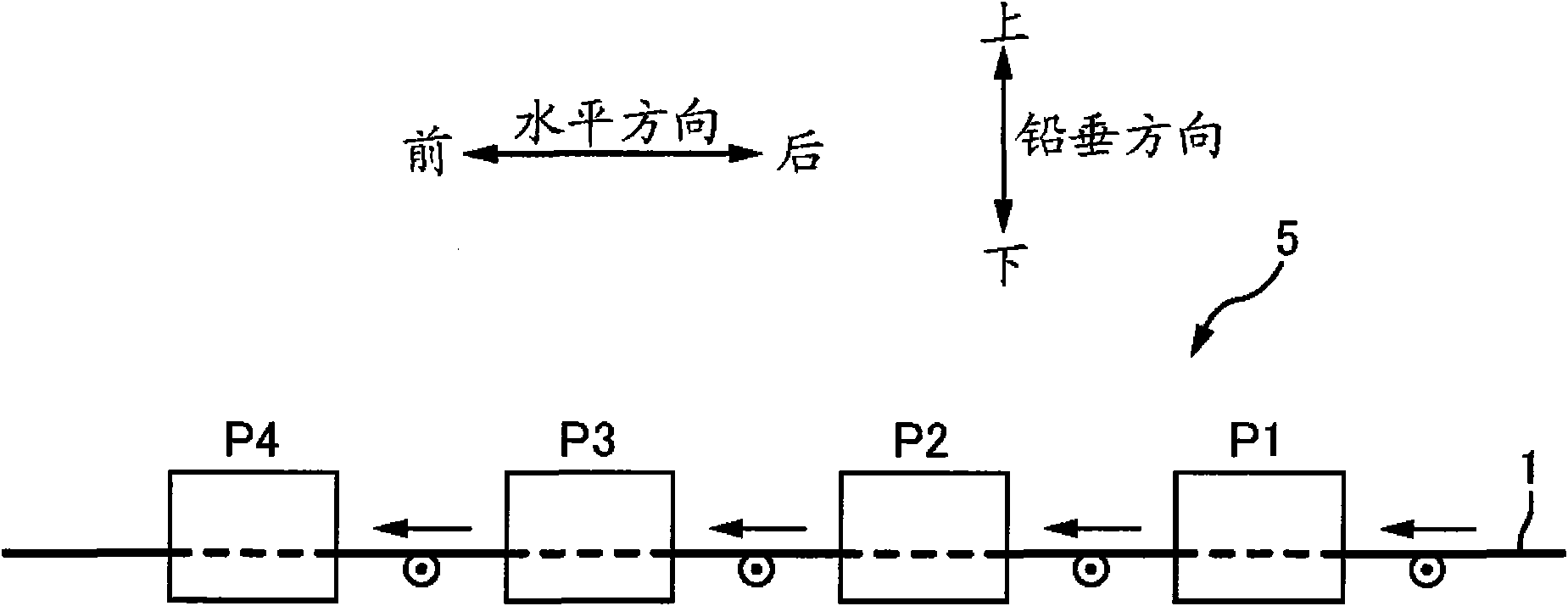

[0118] In addition, as shown in FIG. 4A , the vertical direction is hereinafter also referred to as an up-down direction, and the horizontal direction orthogonal to the vertical direction is hereinafter also referred to as a front-rear direction. Incidentally, “front” in the front-rear direction is the downstream side in the conveyance direction of the belt-shaped workpiece 1 , and “rear” is the upstream side in the conveyance direction of the belt-shaped workpiece 1 . In addition, the upstream side of the processing facility 10 is also r...

no. 2 approach

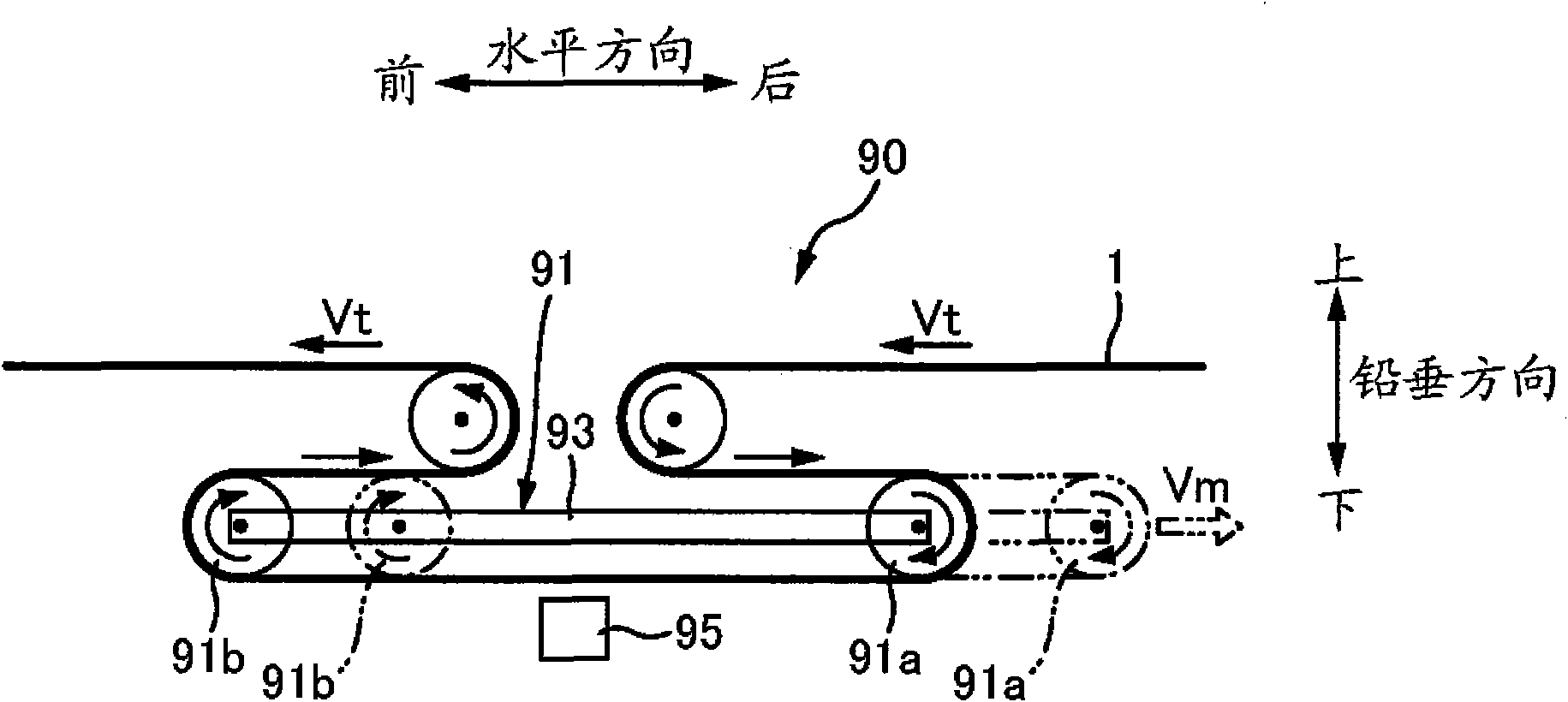

[0163] Fig. 10 is a side view of a processing apparatus 10a according to the second embodiment. In the first embodiment described above, the driving roller 31 b controls the conveyance state of the belt-shaped workpiece 1 in the pressing device 20 . In the present second embodiment, the conveyance state is controlled by a non-driving roller 31d provided with a brake instead of the driving roller 31b and a swing drive device 36 for driving the swing member 34 to swing. In other words, the brake-equipped non-driving roller 31d and the rocking drive device 36 correspond to the "intermittent delivery section". Features other than the above-mentioned features are the same as those in the first embodiment, for example, the tension fluctuation suppressing mechanism 37 is similarly provided.

[0164] The actuator-equipped non-driving roller 31d includes: a non-driving roller 31d installed at the same position as the driving roller 31b instead of the driving roller 31b; and a brake me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com