Nano-precision six-freedom-degree magnetic suspension jiggle station and application

A technology of micro-motion stage and degree of freedom, which is applied in microlithography exposure equipment, optics, instruments, etc., can solve the problems of complex structure of six-degree-of-freedom micro-motion stage, and achieve the effect of light weight, simple structure and convenient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

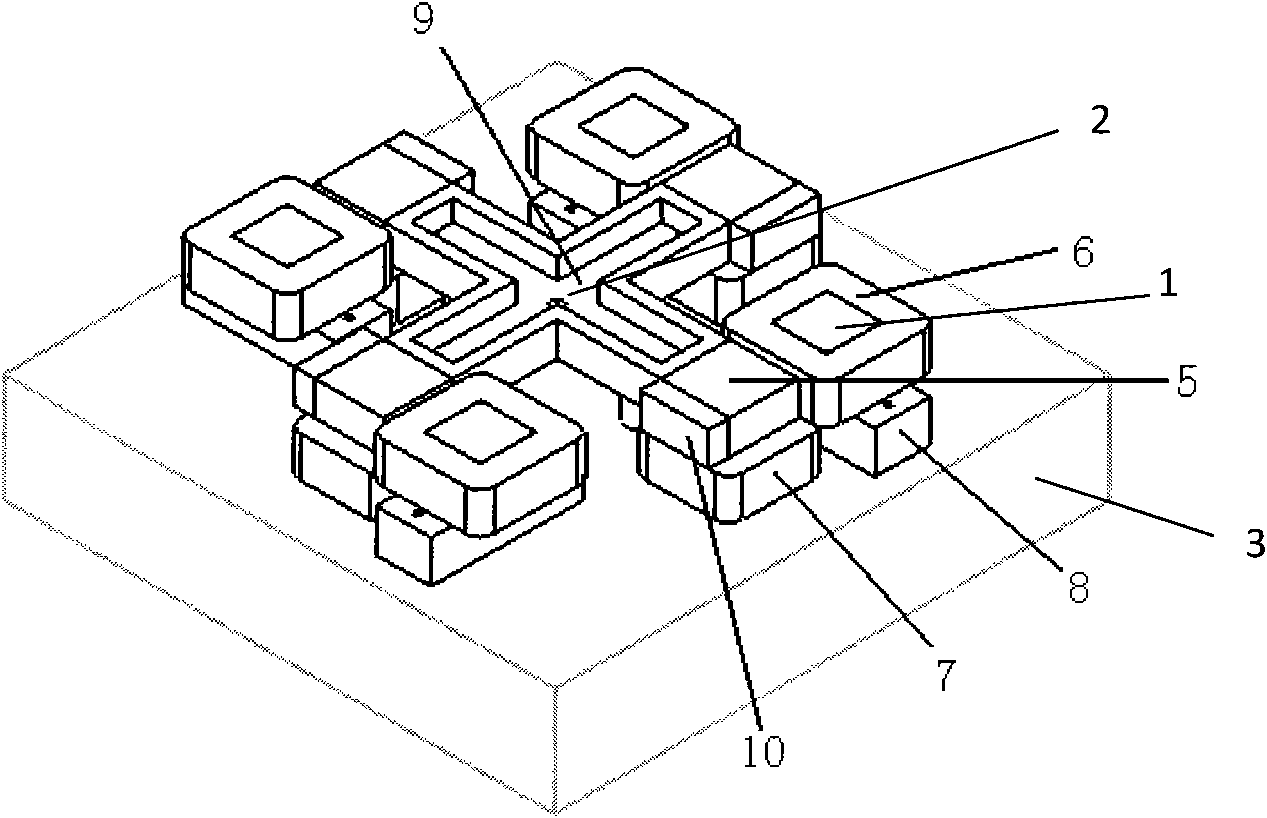

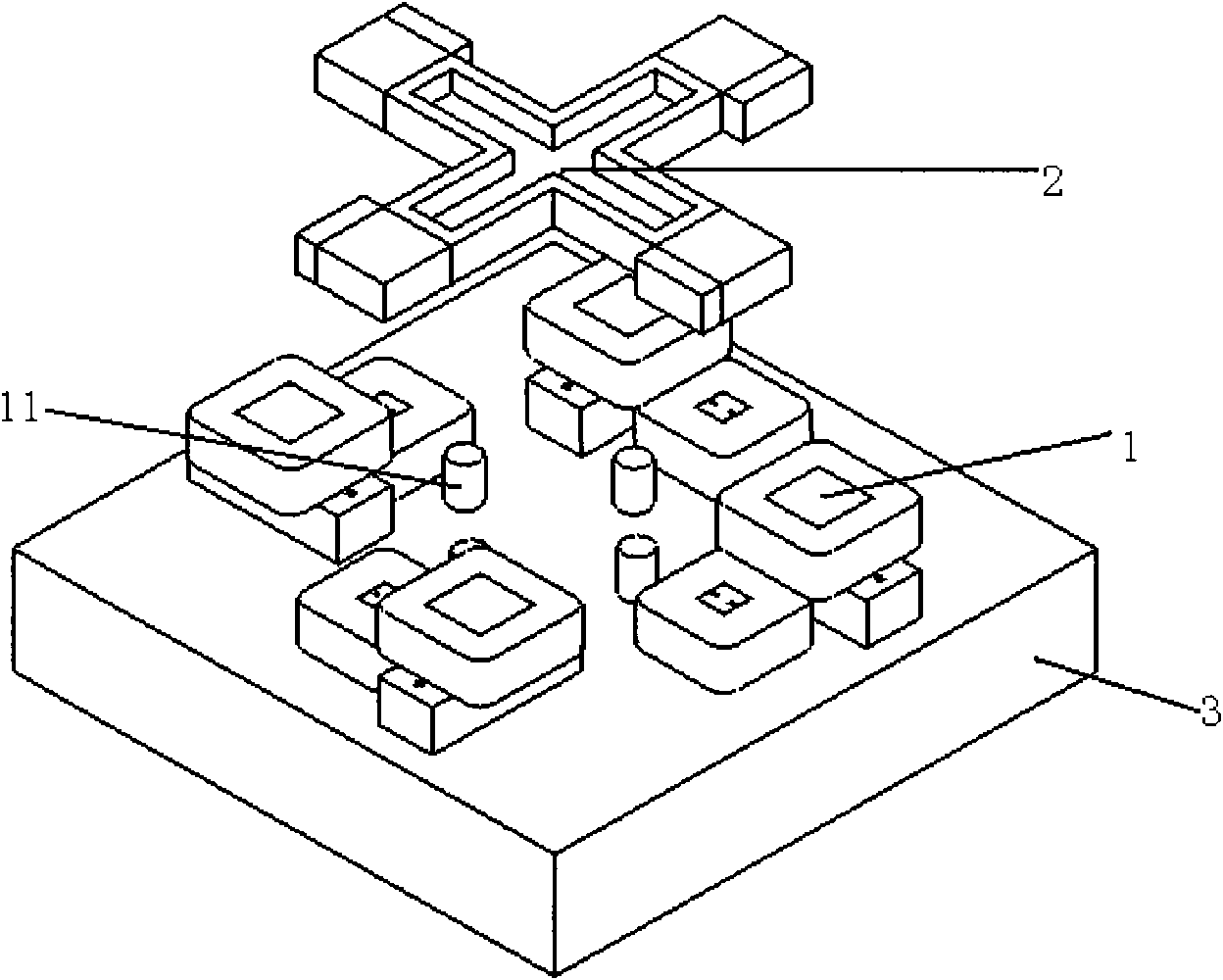

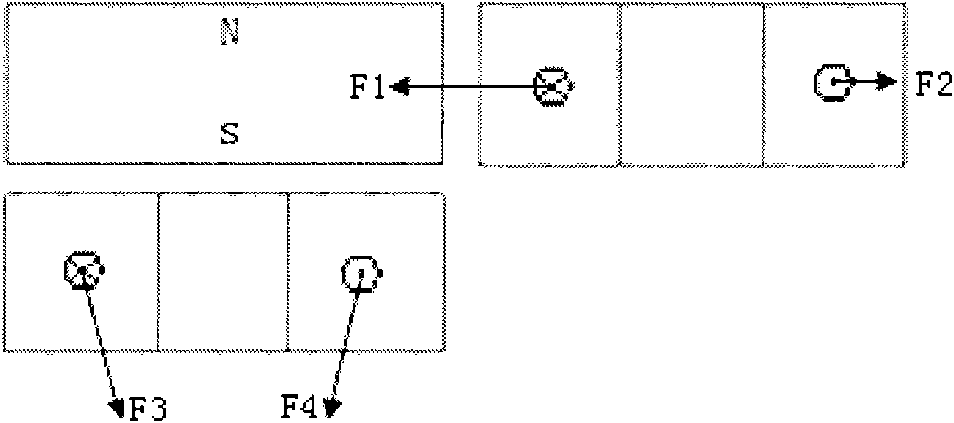

[0020] figure 1 and figure 2 They are the three-dimensional structure diagram and the three-dimensional structure exploded diagram of the nanometer-precision six-degree-of-freedom maglev micro-motion table provided by the present invention, respectively. The micro-motion table contains a cross bracket 9 and four two-degree-of-freedom actuators, and each two-degree-of-freedom actuator is composed of a permanent magnet 5 polarized in the vertical direction, a horizontal force coil 6 and a vertical force coil 7; The magnet 5 is fixed on the end of the cross bracket 9, and the horizontal force coil 6 and the vertical force coil 7 are arranged on the side and the bottom of the permanent magnet 5 respectively, and keep a gap with the permanent magnet. The cross bracket 9 and four permanent magnets 5 polarized in the vertical direction form the mover 2 of the micro-motion stage; the horizontal force coil 6 and the vertical force coil 7 are respectively fixed by the bobbin 8 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com