Vibrating membrane filtration device and industrial wastewater treatment method applying the same

A technology for industrial wastewater and vibration generating devices, which is applied in permeation/dialysis water/sewage treatment, ultrafiltration, etc., can solve the problems of poor economy, decreased water flux, high treatment costs, etc., to improve water treatment efficiency, The effect of maintaining water flux and reducing water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

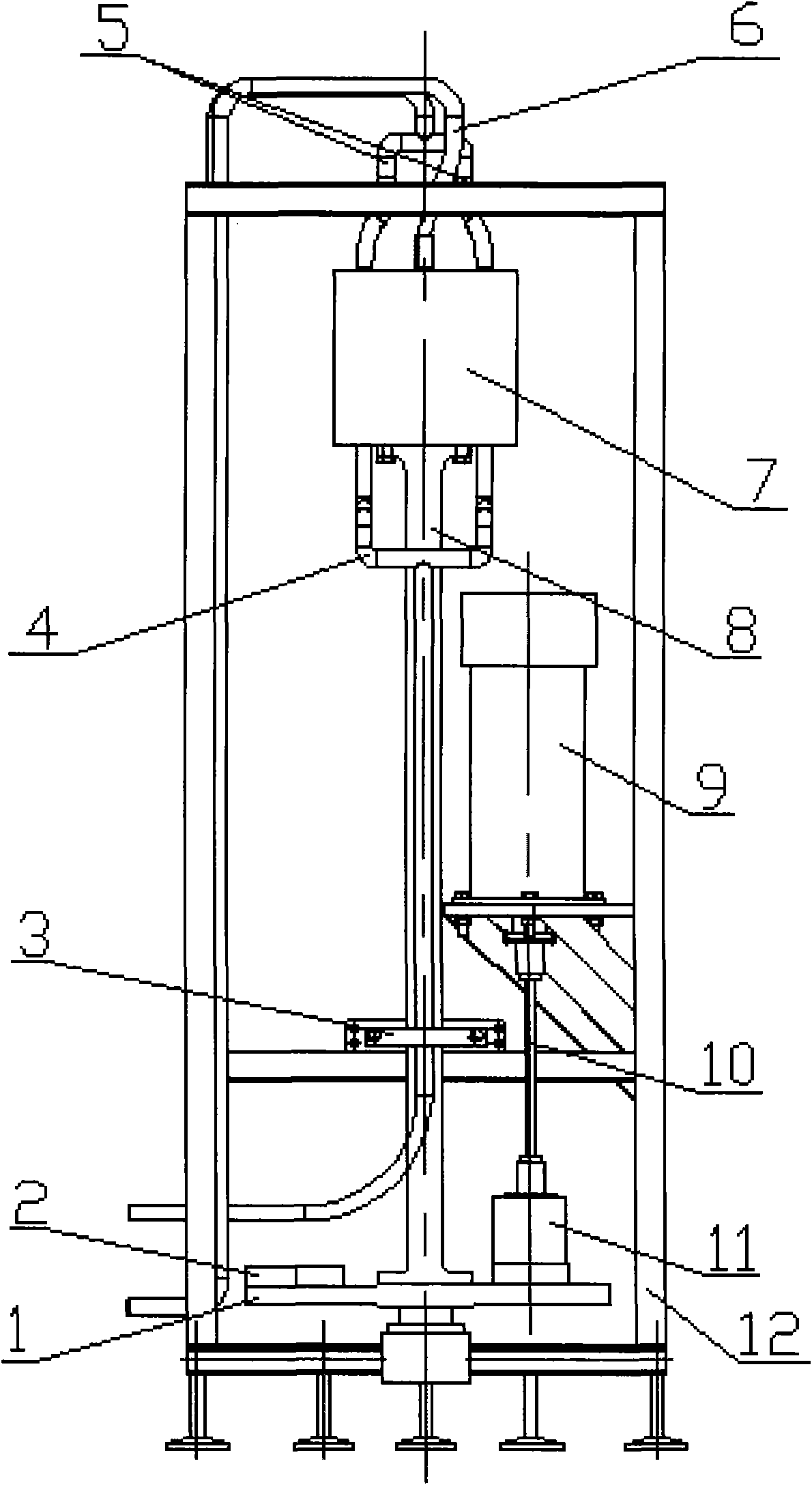

[0021] Example 1: First combine figure 1 Shown is a specific implementation of the vibrating membrane filtration device of the present invention, which consists of a bottom plate 1, a counterweight 2, a clamping mechanism 3, a concentrated water pipe 4, a water inlet pipe 5, a water outlet pipe 6, a membrane module 7, and an elastic spindle 8. , Motor 9, transmission shaft 10, eccentric block 11 and bracket 12 composition. The motor 9 and the membrane module 7 are fixed to the support 12, the elastic main shaft 8 is arranged longitudinally, the lower end of which is fixed to the center of the bottom plate 1, and the upper end is fixed to the bottom of the membrane module 7; the clamping mechanism 3 is fixed to the middle of the bracket 12 to clamp the elastic main shaft 8; the counterweight 2 and the eccentric block 11 are respectively fixed on both sides of the center of the bottom plate 1; the rotating shaft of the motor 9 is connected to the eccentric block 11 through the tra...

Embodiment 2

[0024] Embodiment 2: An industrial wastewater treatment method using the vibrating membrane filtration device described in Embodiment 1. The industrial wastewater is a certain pharmaceutical wastewater: COD is 70,000 mg / L, and the salt content is 5%. The pharmaceutical wastewater is first catalyzed and oxidized by a three-dimensional electrode reactor, and then coagulated and precipitated, and then enters the vibrating membrane filter device for nanofiltration (the filter membrane adopts nanofiltration membrane), and the effluent can meet the requirements of the customer to enter the biochemical system: The COD is 6000mg / L, and the salt content is 0.1%.

Embodiment 3

[0025] Embodiment 3: An industrial wastewater treatment method using the vibrating membrane filtration device described in Embodiment 1. The industrial wastewater is a certain synthetic wastewater: COD is 5000 mg / L and salt content is 5%. The synthetic wastewater is first catalyzed and oxidized through a three-dimensional electrode reactor, and then coagulated and precipitated, and then enters the vibrating membrane filter device for nanofiltration (the filter membrane adopts nanofiltration membrane), and the effluent COD is 80mg / L, which meets the first-level emission standard .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com