Automatic rack-mounting system of numerical control mould pressing encaustic tile production equipment

A technology for automatic racking and production equipment, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of high labor intensity, low degree of automation, and poor work efficiency of workers, so as to save labor and improve work efficiency , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the present invention is not limited to the following embodiments.

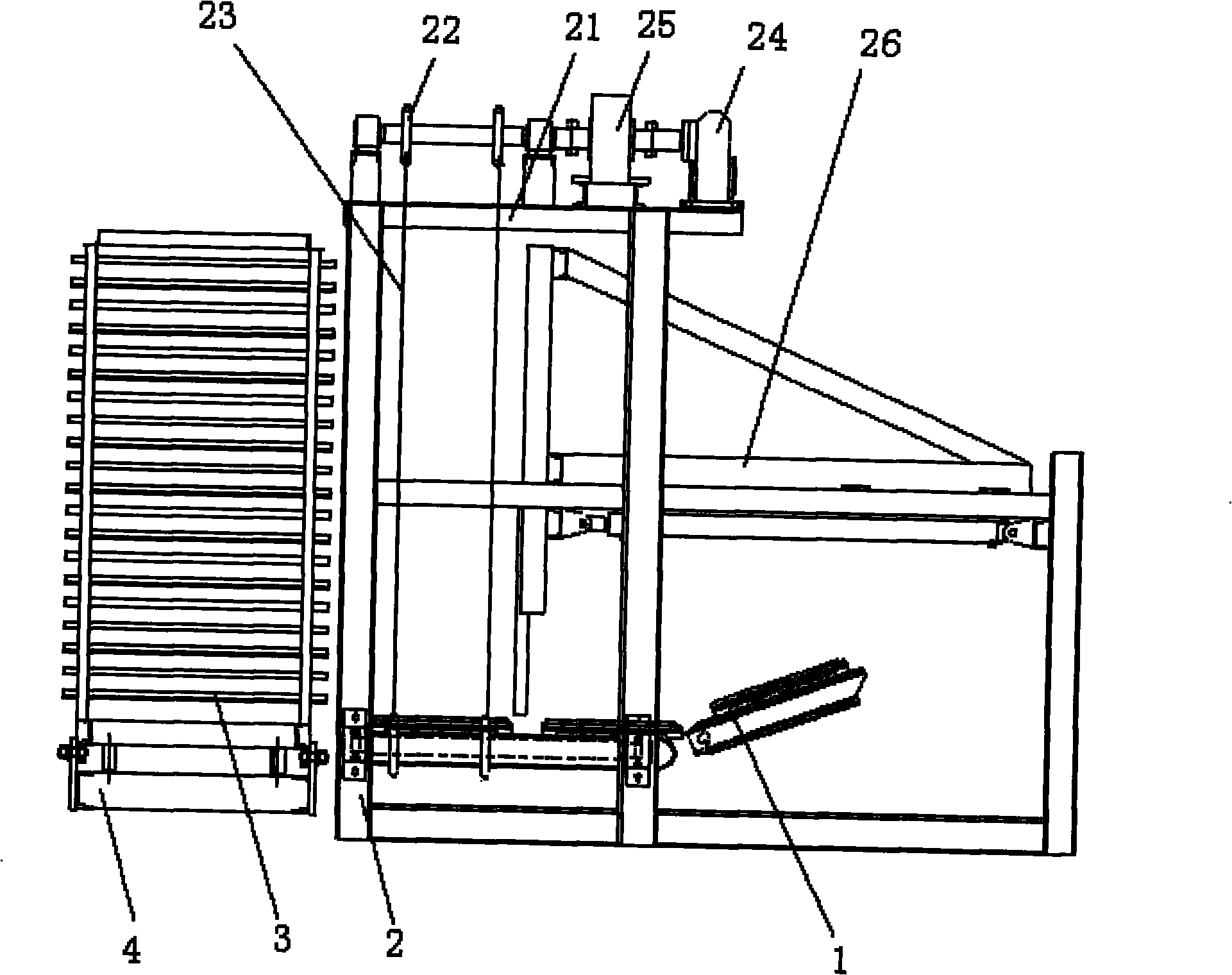

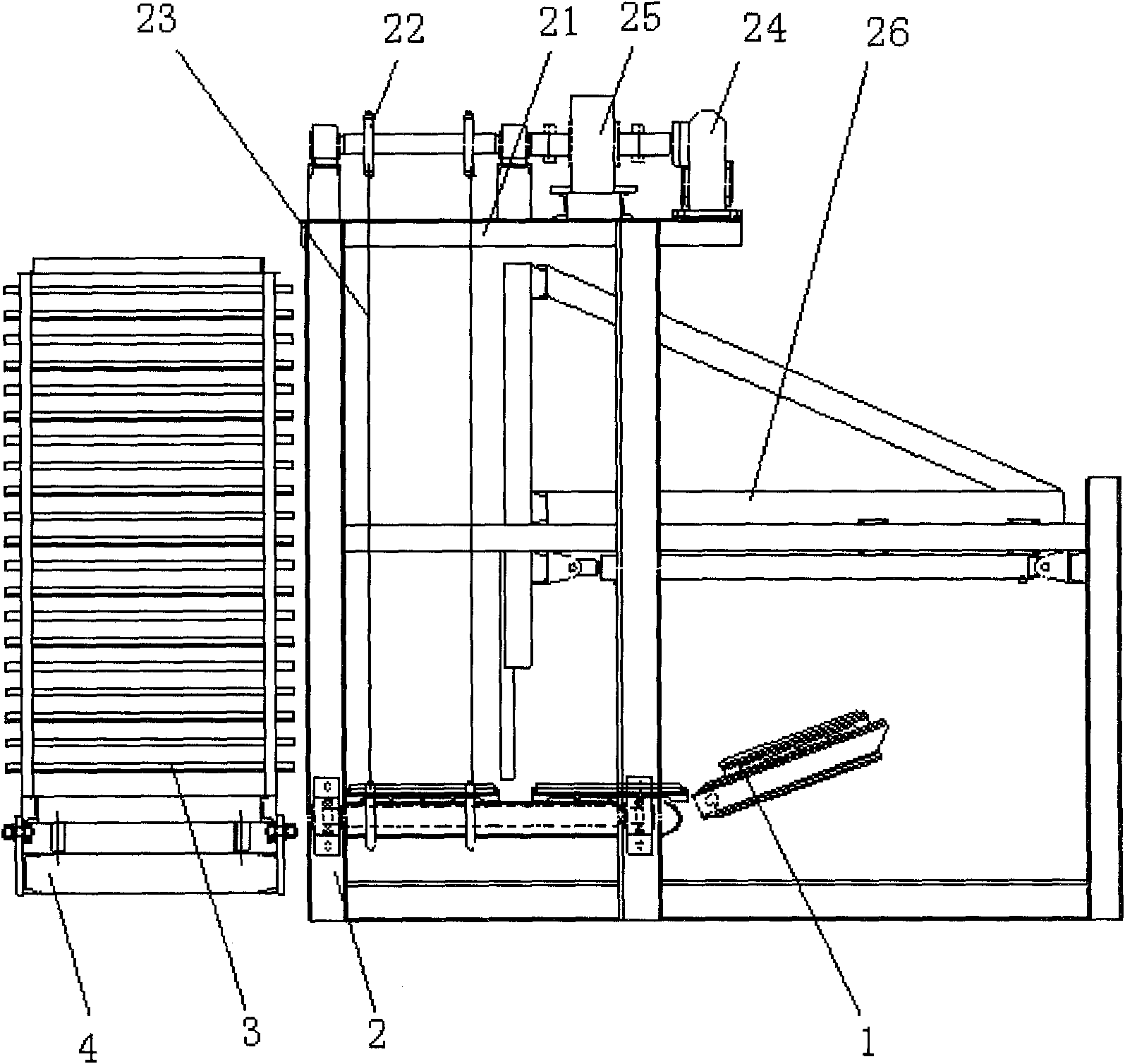

[0015] An automatic mounting system for CNC molded colored tile production equipment, see attached figure 1 And attached figure 2 , the automatic racking system includes a transportation line 1, a racking machine 2, a tile rack 3 and a tile rack traverse mechanism 4, and the racking machine 2 pushes the tiles to be installed on the transport line 1 onto the tile rack 3; the tile rack 3 is arranged on the tile frame traversing mechanism 4, and the tile frame traversing mechanism 4 realizes the lateral movement of the tile frame 3. Mounting machine 2 comprises frame 21 and sprocket wheel 22, chain 23, motor 24, transmission mechanism 25, tile row propulsion mechanism 26 that are installed on frame 21, and sprocket wheel 22 is connected with motor 24 by transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com