In-mould assembly method

An in-mold assembly and master mold technology, which is applied to household components, household appliances, and other household appliances, can solve the problems that the production capacity and yield rate cannot meet the expected goals, the cost of enterprises cannot be greatly reduced, and the quality of assembly personnel is uneven. The effect of overcoming the unevenness of quality, eliminating technical issues in factory space, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

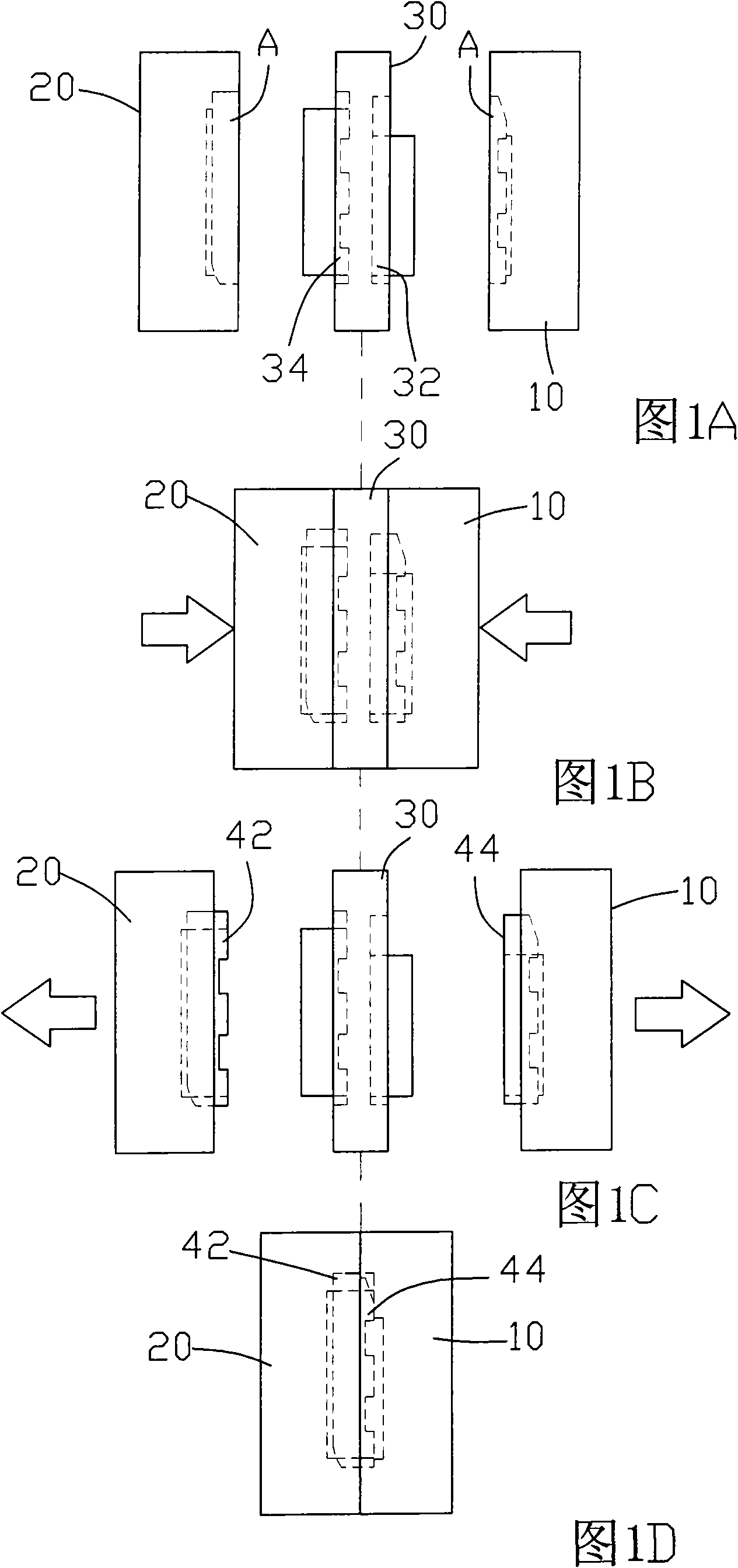

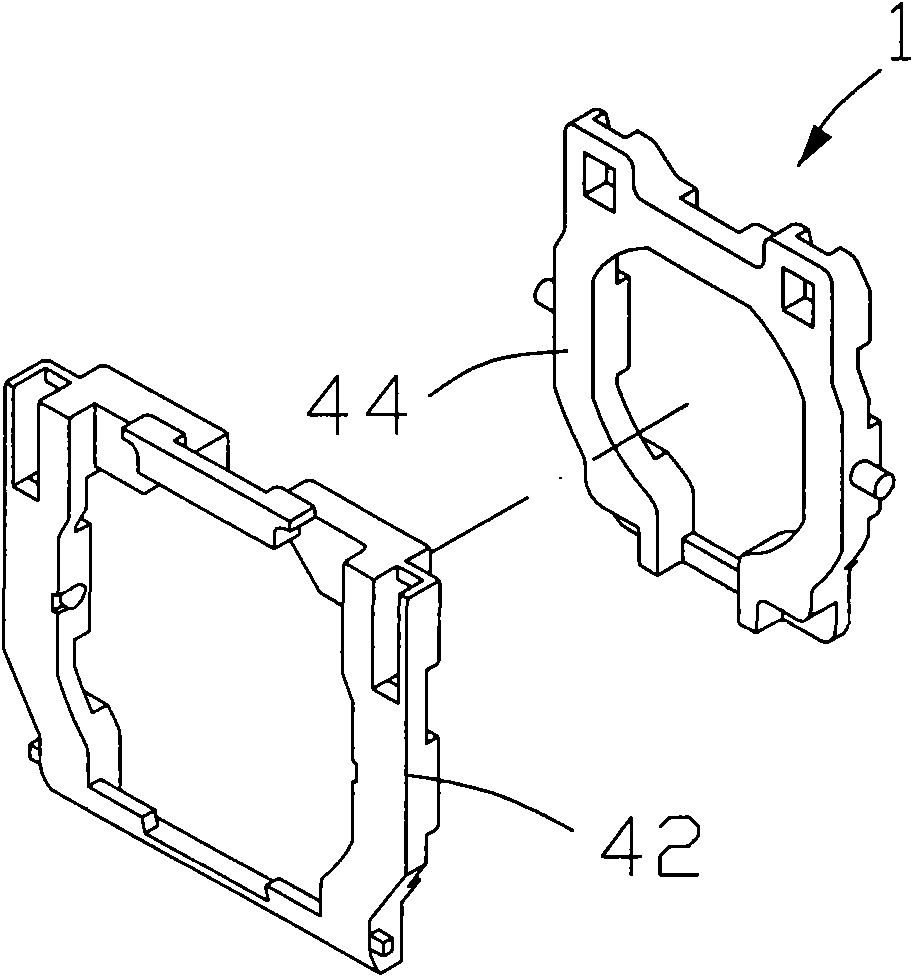

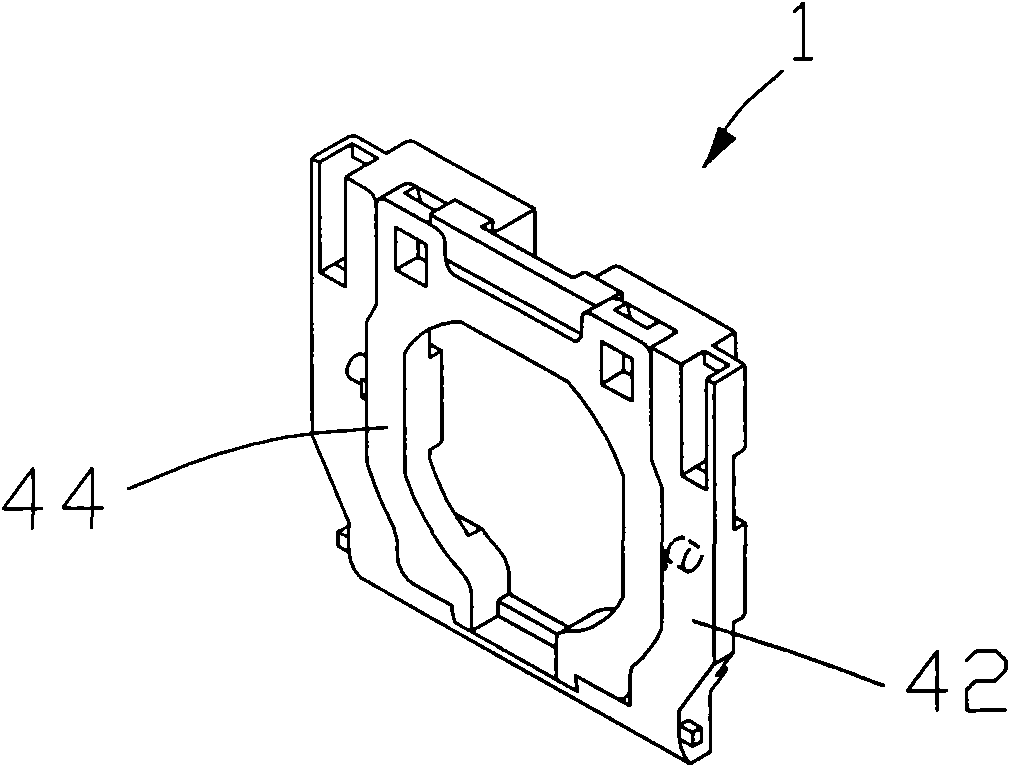

[0020] The present invention provides an in-mold assembly method. The in-mold assembly technology is mainly used in the field of plastic products with a wide range of applications. In order to make the core means of the in-mold assembly technology, it can obtain valuable review members and be familiar with this technical field. Those who need to know more about it and implement it accordingly. The example of the diagram is described in detail with the scissor feet used to support the keycaps of the keyboard, but it is not an attempt to limit the in-mold assembly technology. It is only applied to the structure of the scissor feet. .

[0021] First as Figure 1A~1D As shown, the main structure of the in-mold assembly method of the present invention applied to the scissor foot plastic products includes:

[0022] At least two female molds, the first female mold 10 and the second female mold 20, the first female mold 10 is arranged inside the injection machine (not shown), and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com