Plastics suction mould

A technology of blister molds and blister molds, which is applied in the field of blister molds, can solve the problems of affecting the production quality of films, the sharp corners of films are easy to break, and increase production costs, so as to reduce the depth of film undercuts and save raw materials , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

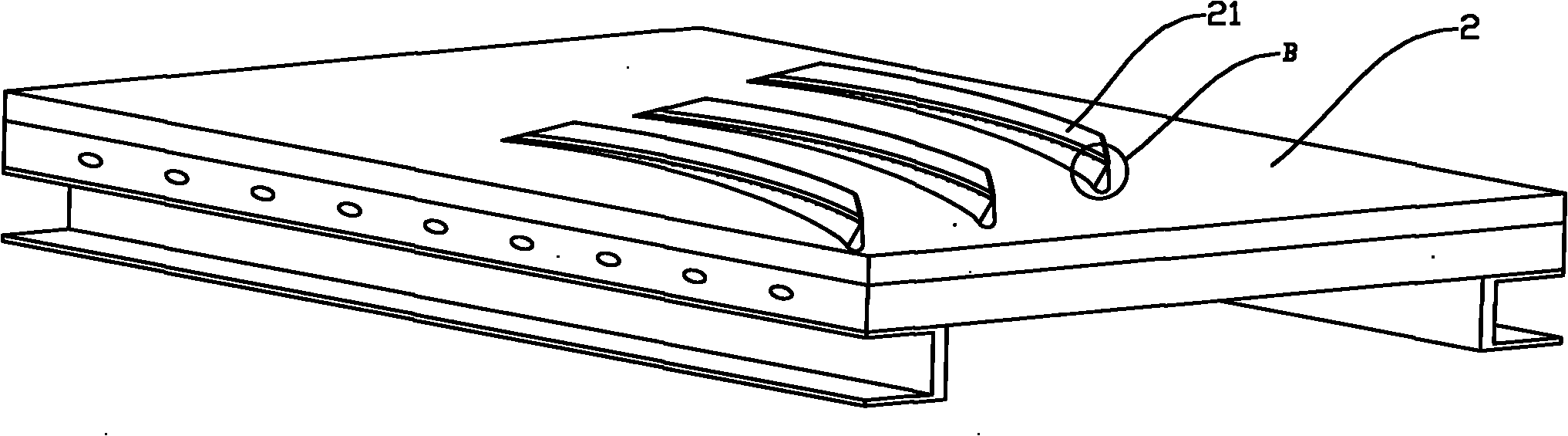

[0033] Such as Figure 4 to Figure 9 Shown:

[0034] The plastic-absorbing mold includes a mold frame 7 on which the pressure frame 3 is arranged, and the mold frame 7 is provided with an air cavity (not shown in the figure).

[0035] The press frame 3 includes a press frame base 4 and a plastic-absorbing part frame 5, and the shape of the plastic-absorbing part frame 5 is the same as that of the plastic-absorbing part to be manufactured. The plastic-absorbing part frame 5 is arranged on the upper end of the pressure frame base 4 . The molded frame 5 of the plastic-absorbing part extends outward along the base body 4 of the press frame, that is, the mold frame 5 of the plastic-absorbing part is larger than the base body 4 of the press frame.

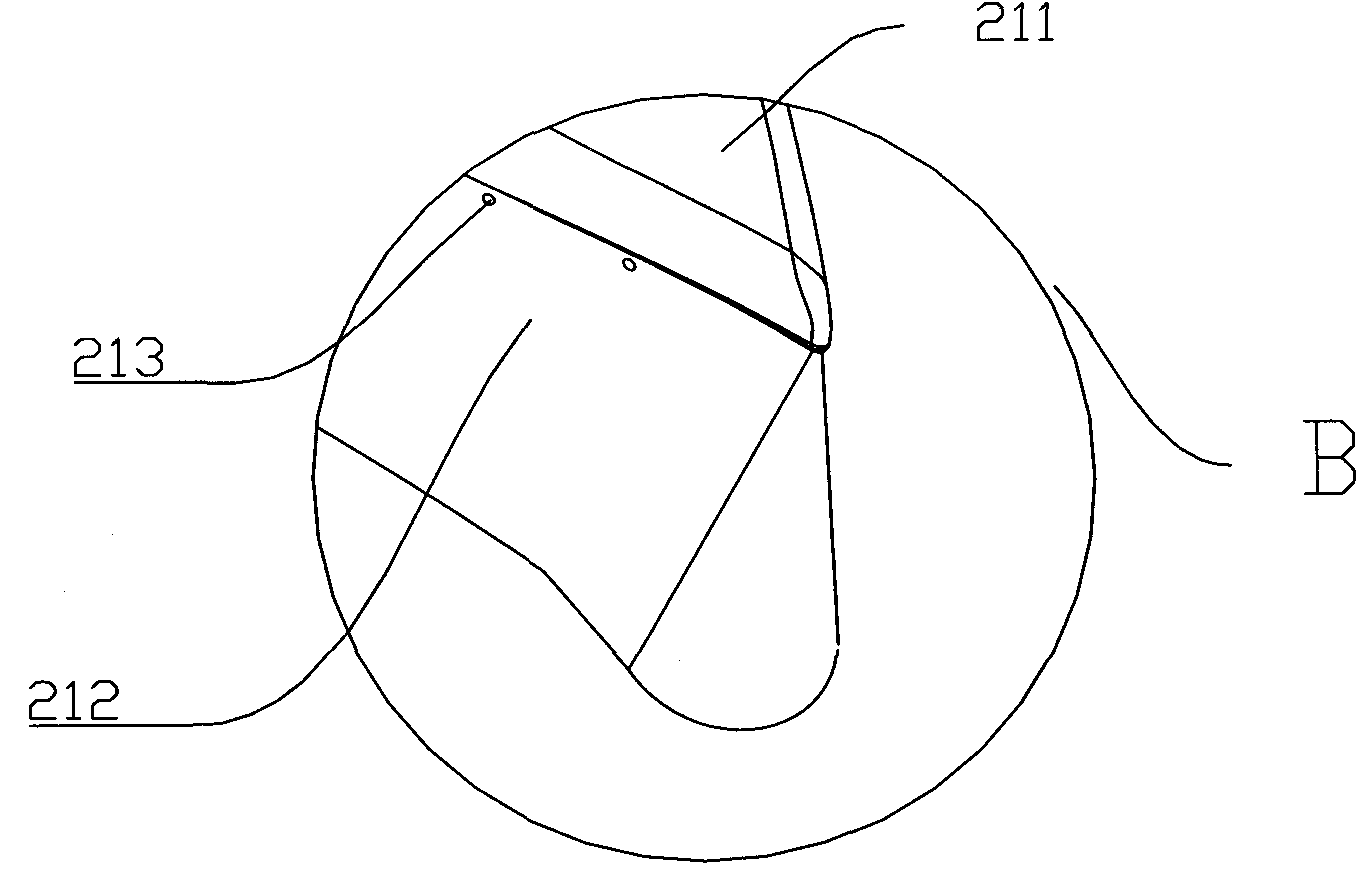

[0036] There is a first sharp corner 51 on the plastic part frame 5, and the first sharp corner 51 is an arc angle between the two sides (52, 53) of the bottom surface of the plastic part frame 5, and the two sides (52, 53) pass throug...

Embodiment 2

[0044] Such as Figure 10 As shown, on the basis of Embodiment 1, the boss 6 has an inclined surface 61 , and the inclined surface 61 is located directly below the first sharp corner 51 . The distance between the junction of the inclined surface 61 and the pressure frame base 4 and the plastic part frame 5 is smaller than the distance between the outermost end of the inclined surface and the plastic part frame 5 . The outermost end of the inclined surface refers to the farthest end of the inclined surface 61 extending outward from the pressure frame base 4 .

[0045] In the blister mold of the present invention, when the film is stretched to a height of 5.2mm and the first sharp angle is 48°, the undercut depth of the film is only 0.5mm, and it is easier to remove the mold after blistering, and the first sharp corner will not be scratched. Break the plastic film, improve the yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com