Plastic suds tub for a washing machine or a washer/dryer

A technology for washing machines and plastic tubs, applied in other washing machines, washing devices, applications, etc., can solve problems such as inability to use, narrow restrictions, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

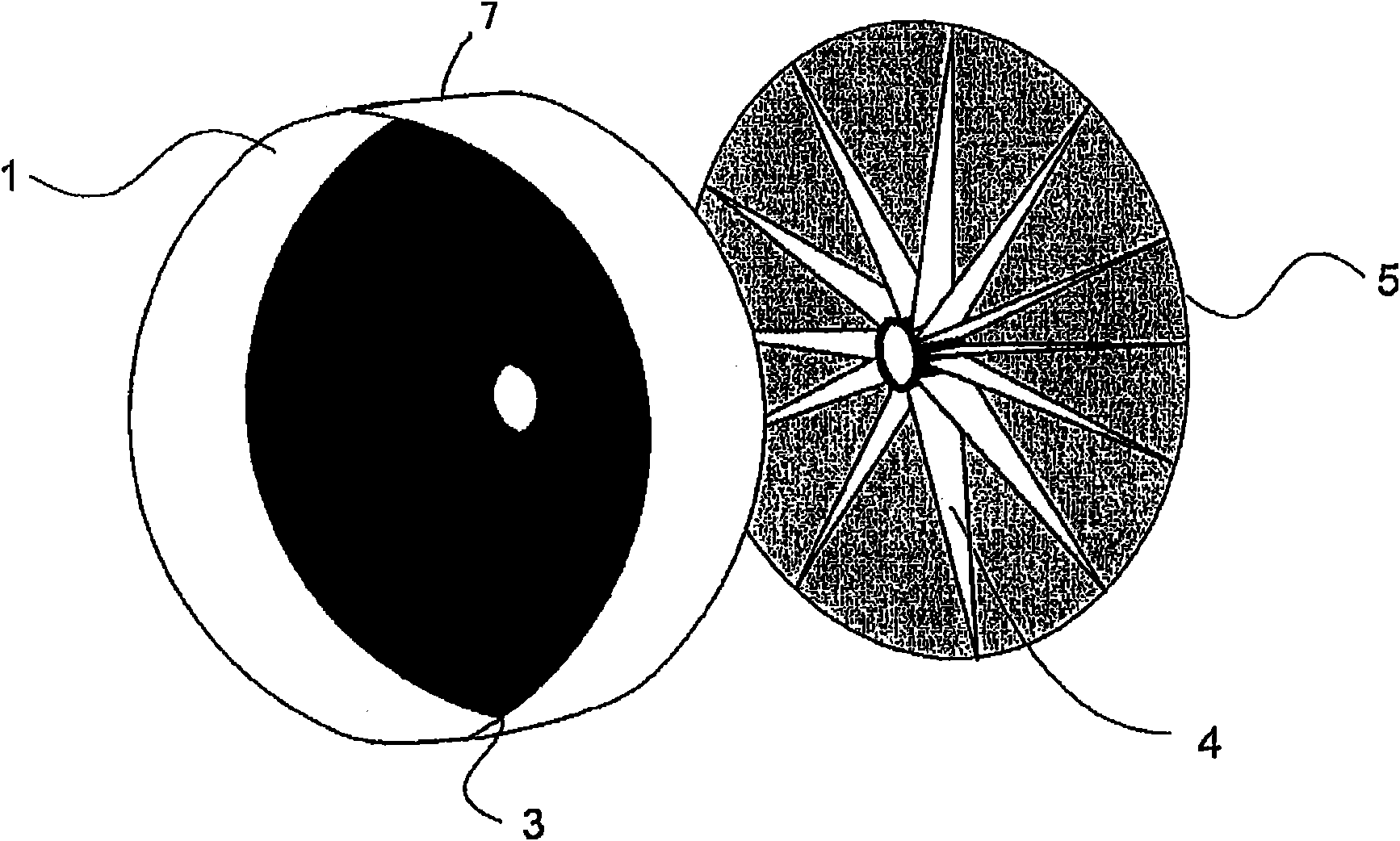

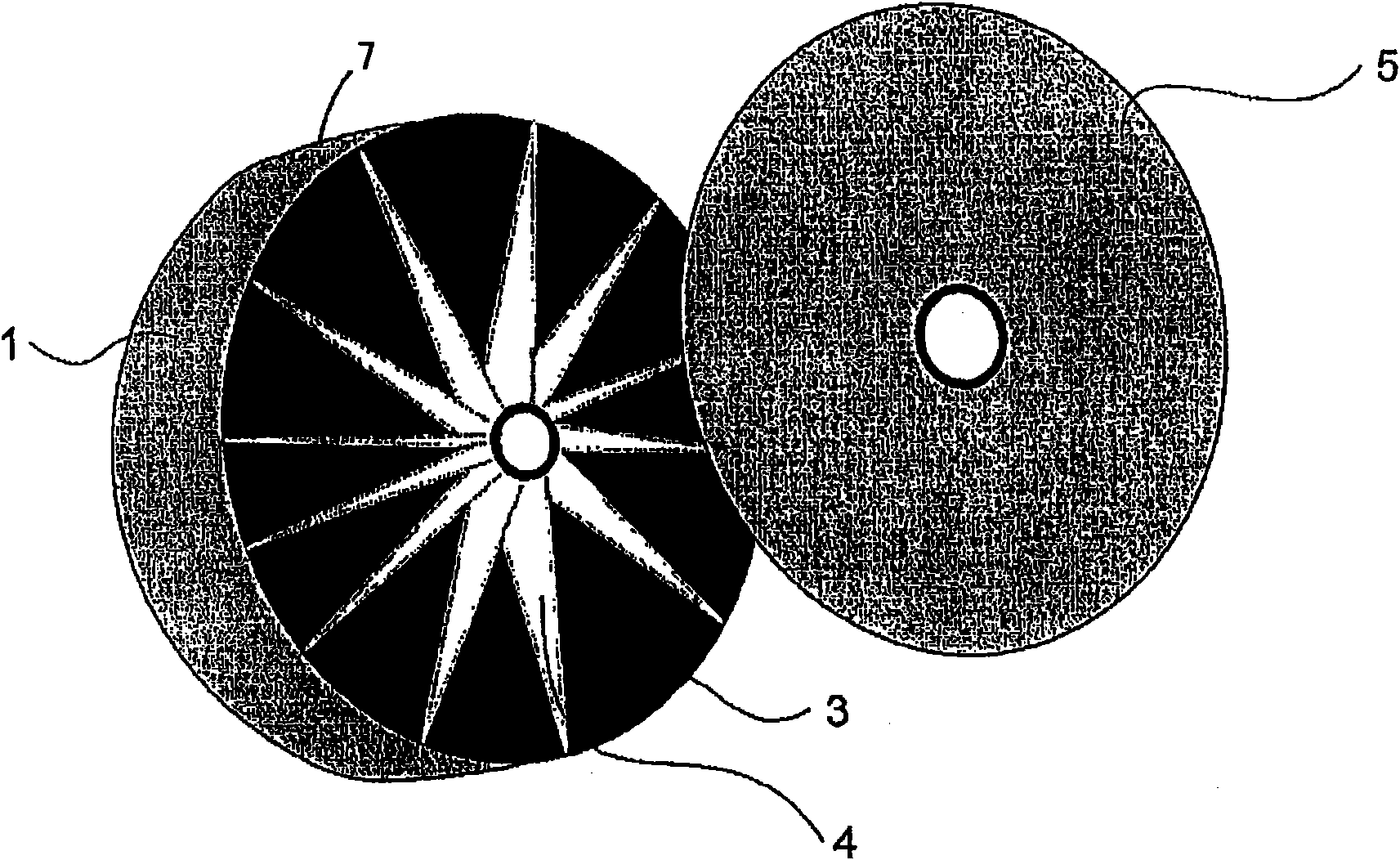

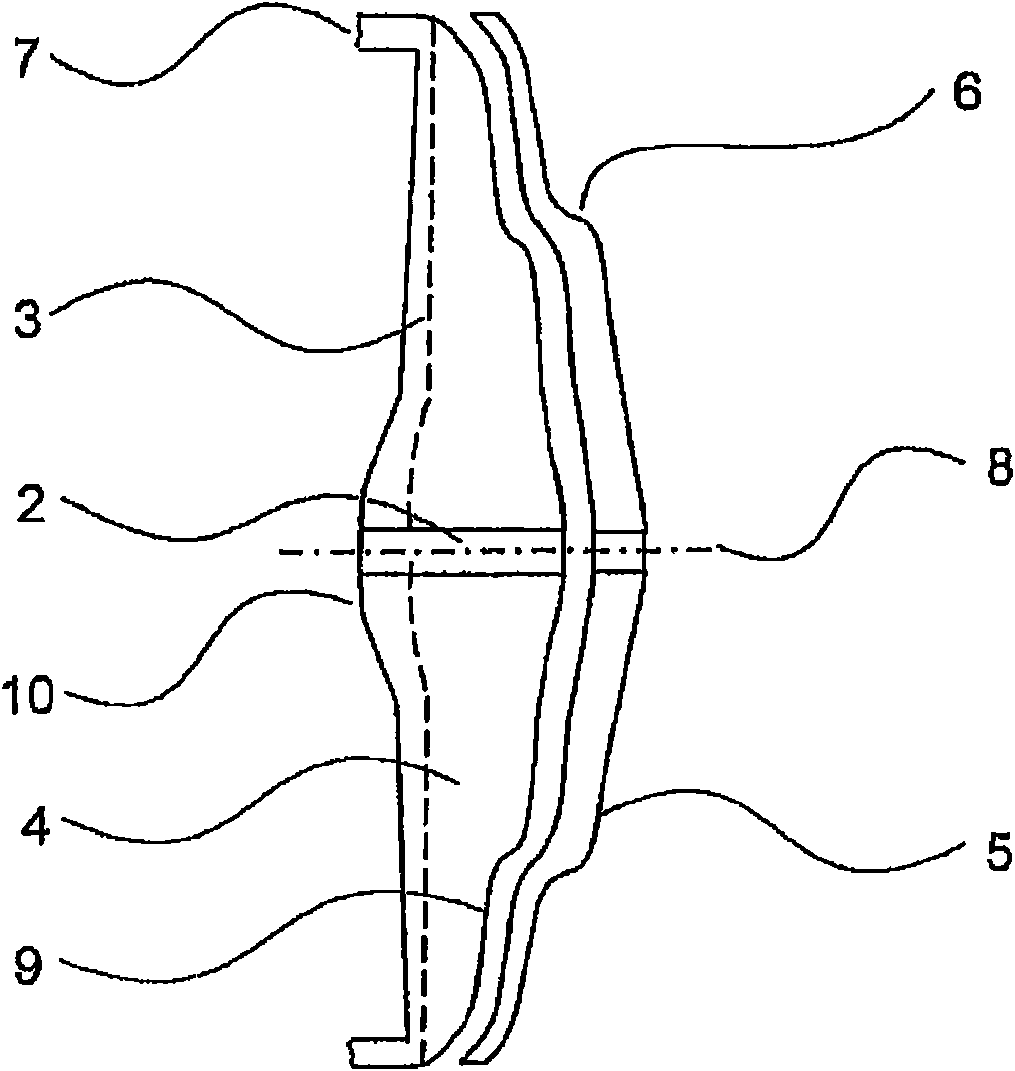

[0043] figure 1 The rear part of the plastic tub 1 is shown from the front in a perspective view. This component comprises the end wall 3 and is produced in one piece by injection moulding. In subsequent operation, this member 1 is firmly connected to the cylinder of the tub 1 , also made of plastic.

[0044] The hollow cylindrical cavity-free bearing mounting 2 is formed centrally in the end wall 3 . This bearing mount is intended to receive a fluid-tight bearing, not shown, for the drive shaft of a laundry drum, also not shown, which is arranged in the tub 1 . The more detailed embodiment of the hollow cylindrical bearing mount 2 is dictated by the corresponding exact design of the bearing to be used, which is not important here. In any case, the bearing mount 2 consists of dense plastic without cavities, since the bearing mount must withstand the forces of the rotating washing drum, which may be adversely affected by unbalanced loads, and must accordingly Designed to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com