Cement composition for self-levelling concrete and self-levelling concrete containing such composition

A technology of self-leveling concrete and cement composition, applied in the field of cement composition, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

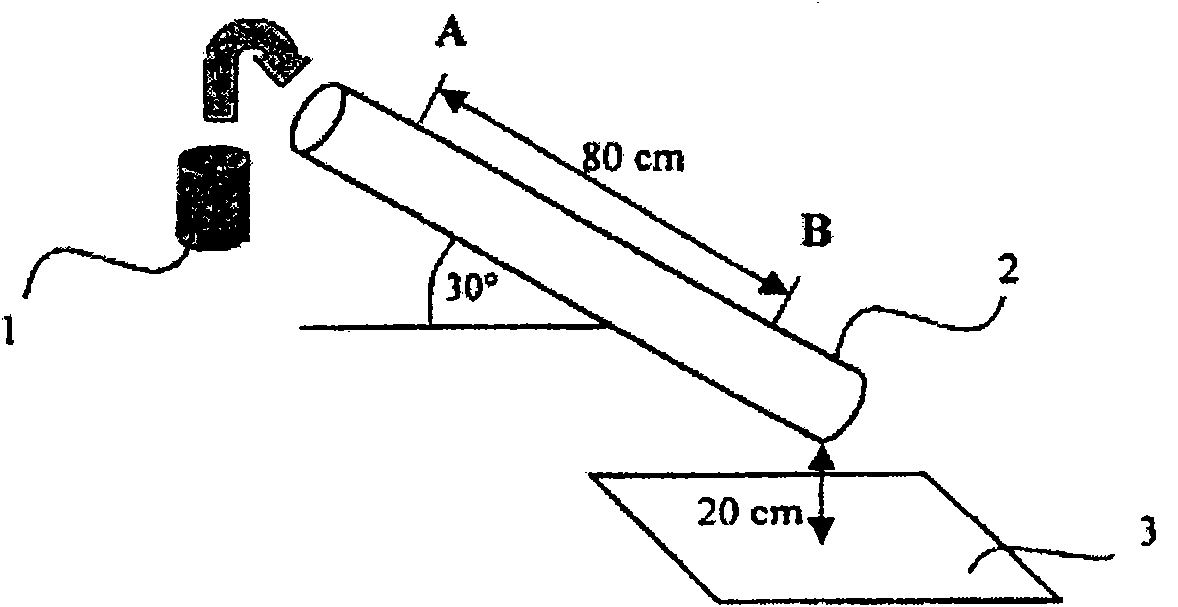

Image

Examples

Embodiment 1( comparative )- Embodiment 2( comparative )- Embodiment 3

[0086] Embodiment 1 (for comparison)-embodiment 2 (for comparison)-embodiment 3 (refer to ratio)-embodiment 4 (the present invention)

[0087] In the first step, comparative examples were carried out using only one reagent. Comparative Example 1 uses only reagents that increase the shear threshold, and Comparative Example 2 uses only reagents that only increase viscosity.

[0088] Table 1 shows the results of these two comparative examples 1 and 2 and example 4 comprising a combination of the two agents and compared to compositions containing fillers in the presence of cohesive agents. This last composition, "Example 3 (Reference)" in all tables, was formulated according to the prior art.

[0089] It has been noted that in Comparative Example 1, which contained only the shear threshold increasing agent, the time in the chute was less than 1 second, reflecting insufficient viscosity, and the sieve stability was greater than 50%. In addition, surface condensation and kinet...

Embodiment 5、6 and 7

[0095] Table 2 shows various concentrations of shear threshold increasing agents and viscosifying agents. Different concentrations of these two reagents have been tested in Examples 5, 6 and 7.

[0096] Table 2

[0097]

[0098] It is worth noting that the performance levels are comparable regardless of their concentration, wherein these concentrations are preferably lower than 0.05 wt% for the first agent and lower than or equal to 0.5 wt% for the second reagent. Therefore, it is possible to obtain self-leveling concrete without fillers by combining these two agents, which has the same performance level compared to self-leveling concrete with fillers.

Embodiment 11

[0104] Example 11 (reference containing filler) and Example 12

[0105] A Portland cement differing mainly in its strength level, namely CEM II 45.5R cement, was tested. The results are shown in Table 4.

[0106] Table 4

[0107]

[0108] Mixtures of the two agents of the present invention are also effective with this cement. The level of performance obtained is comparable to that of concrete containing fillers (Ref. Example 11).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com