Multicore communication cable comprehensive tester

The technology of a comprehensive tester and communication cable is applied in the field of multi-core communication cable comprehensive tester, which can solve the problems of increasing the workload of construction and maintenance, affecting the accuracy of measurement, and slowing down the work progress, so as to achieve high test reliability, Good anti-interference, easy to use on-site effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

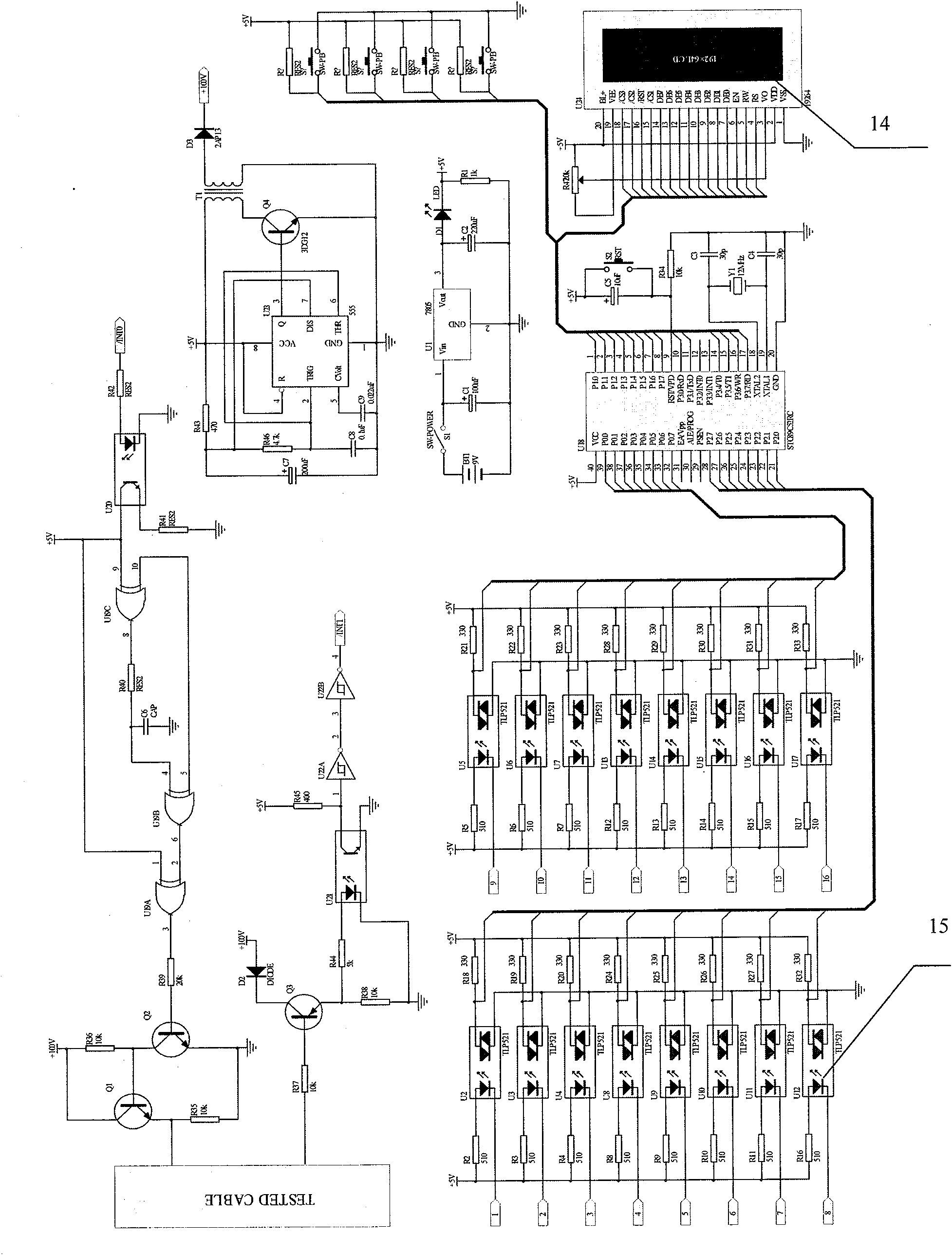

[0027] A cable comprehensive tester, its hardware mainly has two parts: a line sequence test signal transmitter 7 and a host 11, wherein the line sequence test signal transmitter includes a coded CPU8 and a coded sending circuit connected to the coded CPU8 and controlled by the coded CPU8 9. The host computer 11 includes several parts such as a decoding CPU 3, an encoding receiving circuit 5, a fault point ranging signal transmitting / receiving circuit 1, a display 2, and a keyboard 4. The encoding receiving circuit 5 and the fault point ranging signal transmitting / receiving circuit 1. The display 2 and the keyboard 4 are respectively connected to the decoding CPU3 and controlled by the decoding CPU3. The encoding receiving circuit 5 adopts a low-speed AD chip 14, and the encoding transmitting circuit 9 and the encoding receiving circuit 5 are provided with an optocoupler 15 Isolated from the cable 6 to be tested.

[0028] The peripheral interface of the wire sequence test sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com