Robust design of diagnostic enabling conditions for scr nox conversion efficiency monitor

A catalytic converter and diagnostic testing technology, which is applied to diagnostic devices, chemical instruments and methods, and mechanical equipment of exhaust gas treatment devices, and can solve problems such as false indications of faulty catalytic converters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

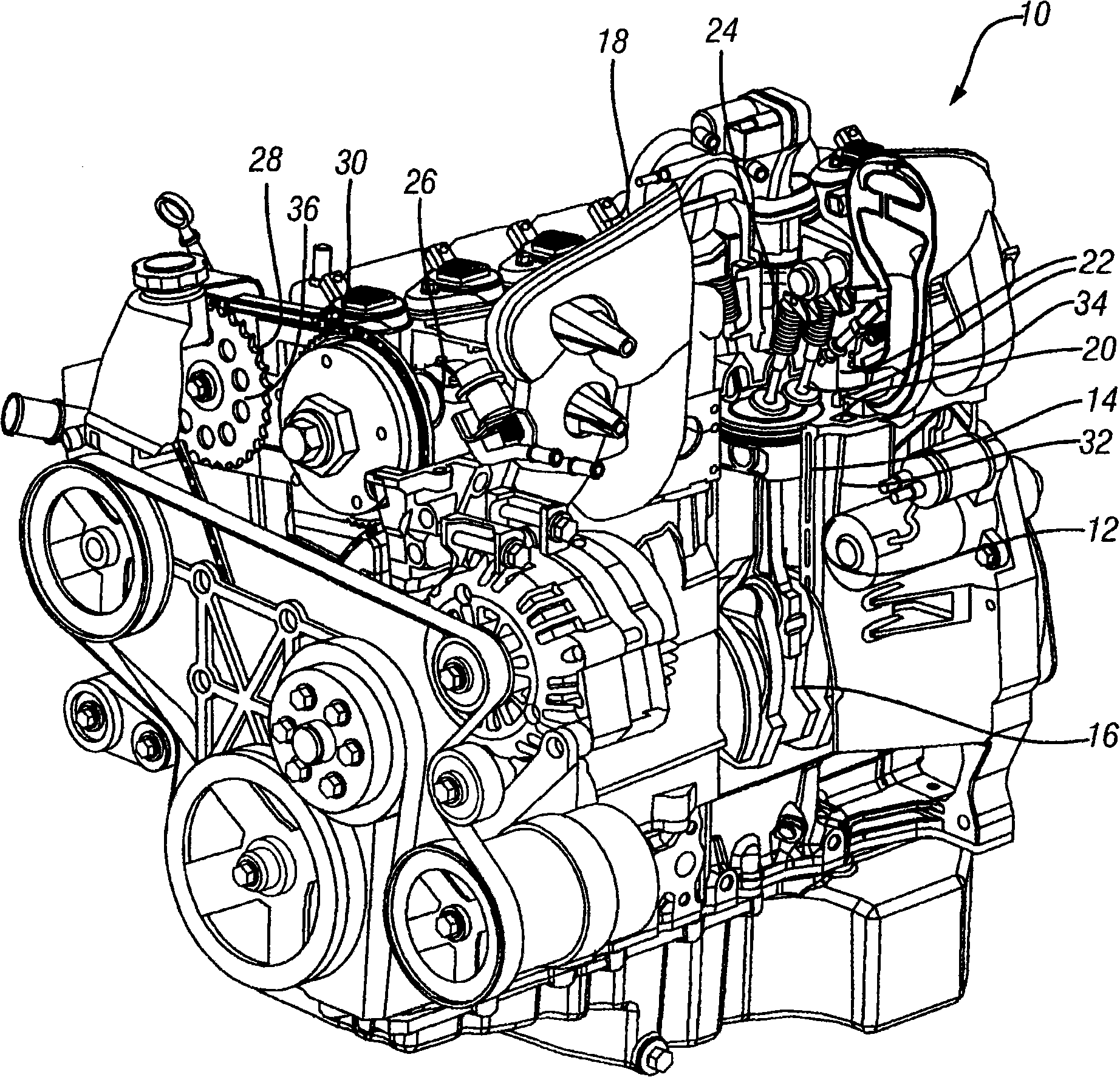

[0028] Referring now to the accompanying drawings, which are shown only to illustrate certain exemplary embodiments and are not intended to limit them, figure 1 It is a partial view of an exemplary diesel engine according to the present invention. The engine 10 generally includes a plurality of cylinders 12 with a reciprocating piston 14 connected to a crankshaft 16 therein. The present invention is generally applicable to direct injection four-stroke compression ignition engines. The end of the cylinder is closed by the cylinder head 18 so that the cylinder and the piston define a variable volume combustion chamber 20.

[0029] The cylinder head is provided with an intake valve 22, which controls the timing and flow of intake air into the cylinder during the intake stroke of the piston. The exhaust valve 24 in the cylinder head controls the timing and flow of exhaust products from the combustion chamber during the exhaust stroke of the piston. In the engine shown, each cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com