Method for producing a quaternary ammonium chitosan/polyving akohol membrane

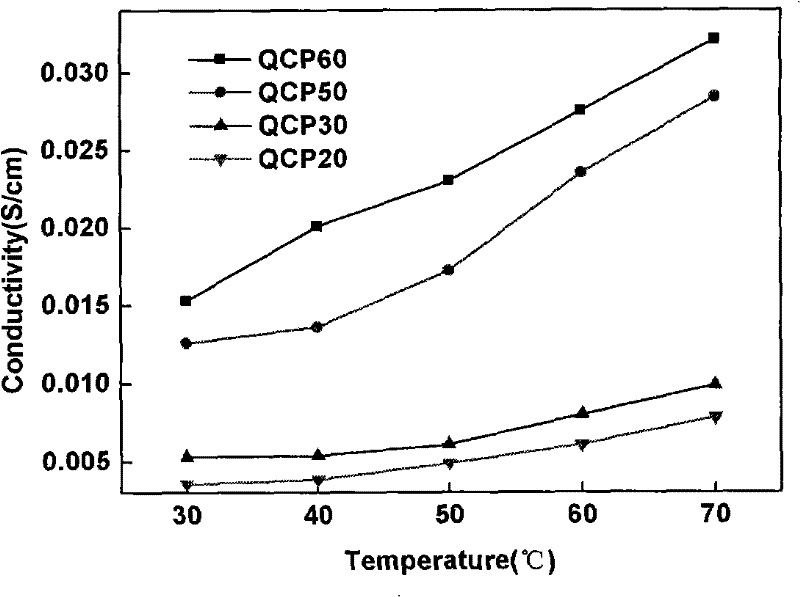

A technology of quaternized chitosan and polyvinyl alcohol film, which is applied in electrical components, circuits, battery electrodes, etc., can solve the problem of alcohol barrier properties of easily poisoned proton exchange membranes, expensive Pt catalysts, and insufficient conductivity of new materials, etc. The problem is to reduce the methanol permeability coefficient, improve the electrical conductivity, and achieve the effect of low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific preparation steps of the preparation method of quaternized chitosan polyvinyl alcohol film are as follows:

[0026] (1) Synthesis of quaternized chitosan

[0027] Chitosan reacts with epoxy groups to introduce quaternary ammonium groups. Weigh 2g of chitosan and place it in a three-necked bottle, add 100ml of 1wt% acetic acid solution, and stir to make the chitosan completely dissolve. The temperature of the water bath was raised to 80°C, 8g of glycidyltrimethylammonium chloride was added at one time, and the reaction was stirred at constant temperature for 8h. Such as figure 1 Shown is the reaction formula of chitosan and glycidyltrimethylammonium chloride.

[0028] (2) washing, drying

[0029] The resulting solution was precipitated with absolute ethanol, filtered, washed several times with absolute ethanol, and dried at 60° C. for 24 hours to obtain light yellow quaternized chitosan solid.

[0030] (3) Synthesis of quaternized chitosan / polyvinyl alc...

Embodiment 2

[0035] A preparation method of quaternized chitosan / polyvinyl alcohol film, the method may further comprise the steps:

[0036] (1) Synthesis of quaternized chitosan

[0037] Chitosan is dissolved in the dilute acetic acid solution that mass fraction is 1%, through sufficient stirring until completely dissolving, makes the chitosan dilute solution that mass fraction is 0.5%, then adds the quality that is 2 times of mass fraction of chitosan Substances with epoxy groups allow chitosan to react with epoxy groups to introduce quaternary ammonium groups to generate quaternized chitosan solutions;

[0038] (2) washing, drying

[0039] The quaternized chitosan solution obtained in step (1) was precipitated with absolute ethanol, filtered, washed several times with absolute ethanol, and dried at 50° C. for 12 hours to obtain a pale yellow quaternized chitosan solid;

[0040] (3) Synthesis of quaternized chitosan / polyvinyl alcohol film

[0041] Take a certain amount of quaternized ...

Embodiment 3

[0045] A preparation method of quaternized chitosan / polyvinyl alcohol film, the method may further comprise the steps:

[0046] (1) Synthesis of quaternized chitosan

[0047] Chitosan is dissolved in the dilute acetic acid solution that mass fraction is 4%, through sufficient stirring until dissolving completely, the chitosan dilute solution that makes mass fraction is 4%, then adds the quality that is 6 times of chitosan quality Substances with epoxy groups allow chitosan to react with epoxy groups to introduce quaternary ammonium groups to generate quaternized chitosan solutions;

[0048] (2) washing, drying

[0049] The quaternized chitosan solution obtained in step (1) was precipitated with absolute ethanol, filtered, washed several times with absolute ethanol, and dried at 80° C. for 48 hours to obtain a pale yellow quaternized chitosan solid;

[0050] (3) Synthesis of quaternized chitosan / polyvinyl alcohol film

[0051] Take a certain amount of quaternized chitosan an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com