Special card sheet for laser printer and preparation method thereof

A technology of laser printers and special certificates, which is applied to information-carrying cards, printing, printed matter, etc., can solve the problems of complex production process, inability to adapt to on-site certificate production, and long time for card production, so as to achieve simple production process and shorten card production time and reduce the cost of card making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a card material dedicated to a laser printer, comprising the steps of:

[0020] (1) Preparation of adhesive solution: Add deionized water and ethanol with a weight ratio of 1:2 into a stainless steel bucket, stir evenly, then put in adhesive, continue stirring for 1 hour, start to heat up to 40°C and maintain 1 hour, then down to room temperature, the binder solution was obtained;

[0021] (2) Preparation of pigment slurry: adding the inorganic pigment and dispersant to the mixed solution of deionized water and ethanol with a weight ratio of 1:3, stirring, pre-dispersing and shearing dispersion, to prepare the pigment slurry;

[0022] (3) Prepare the toner receiving layer coating solution: mix the binder solution and the pigment slurry, add a curing agent and a wetting agent to prepare the toner receiving layer coating solution;

[0023] (4) Coating the toner-receiving layer coating solution on the upper surface of the film base, the coating meth...

Embodiment 1

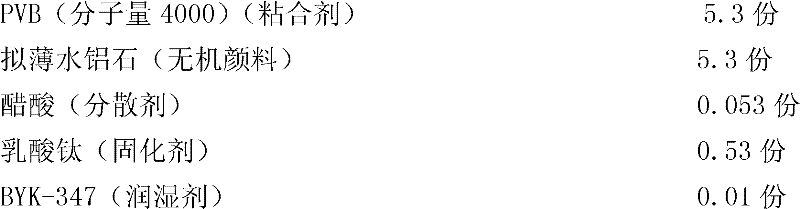

[0026] Sheet base selects PET white sheet base for use, and each component of the toner receiving layer coated on its surface and the parts by weight of each component are as follows:

[0027]

[0028]

[0029] The preparation process of the special card material for laser printers is as follows:

[0030] 1. Prepare adhesive solution: Weigh 15.9 parts of deionized water and 31.8 parts of ethanol, add them into a stainless steel bucket, stir evenly, then put 5.3 parts of PVB into it while stirring, continue stirring for 1 hour, and start to heat up to 40°C and maintained for 1 hour, then lowered to room temperature to obtain PVB solution (adhesive solution);

[0031] 2. Preparation of pigment slurry: according to the formula, add the remaining amount of deionized water (5.3 parts) and the remaining amount of ethanol (15.9 parts) into a stainless steel bucket, add 0.053 parts of acetic acid, stir well, add 5.3 parts of pseudo thin water Aluminum stone, continue to stir an...

Embodiment 2

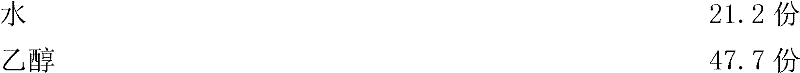

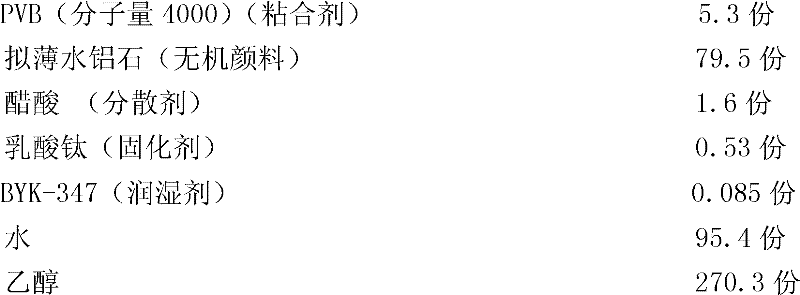

[0035] Sheet base selects PET white sheet base for use, and each component of the toner receiving layer coated on its surface and the parts by weight of each component are as follows:

[0036]

[0037] The preparation process of the special card material for laser printers is as follows:

[0038] 1. Preparation of adhesive solution: Weigh 15.9 parts of deionized water and 31.8 parts of ethanol, add them into a stainless steel bucket, stir evenly, then put 5.3 parts of PVB into it under stirring, continue stirring for 1 hour, and start to heat up to Maintain at 40°C for 1 hour, then drop to room temperature to obtain PVB solution (adhesive solution);

[0039] 2. Preparation of pigment slurry: according to the formula, add the remaining amount of deionized water (79.5 parts) and the remaining amount of ethanol (238.5 parts) into a stainless steel bucket, add 1.6 parts of acetic acid, stir well, add 79.5 parts of pseudo thin water Aluminum stone, continue to stir and pre-disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com