Full-automatic screen printer

A screen printing machine, fully automatic technology, applied in the direction of screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of unstable positioning, increasing the number of machines and equipment, increasing the working hours, etc., to achieve fast positioning and punching Accurate, pave and increase friction, ensure the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

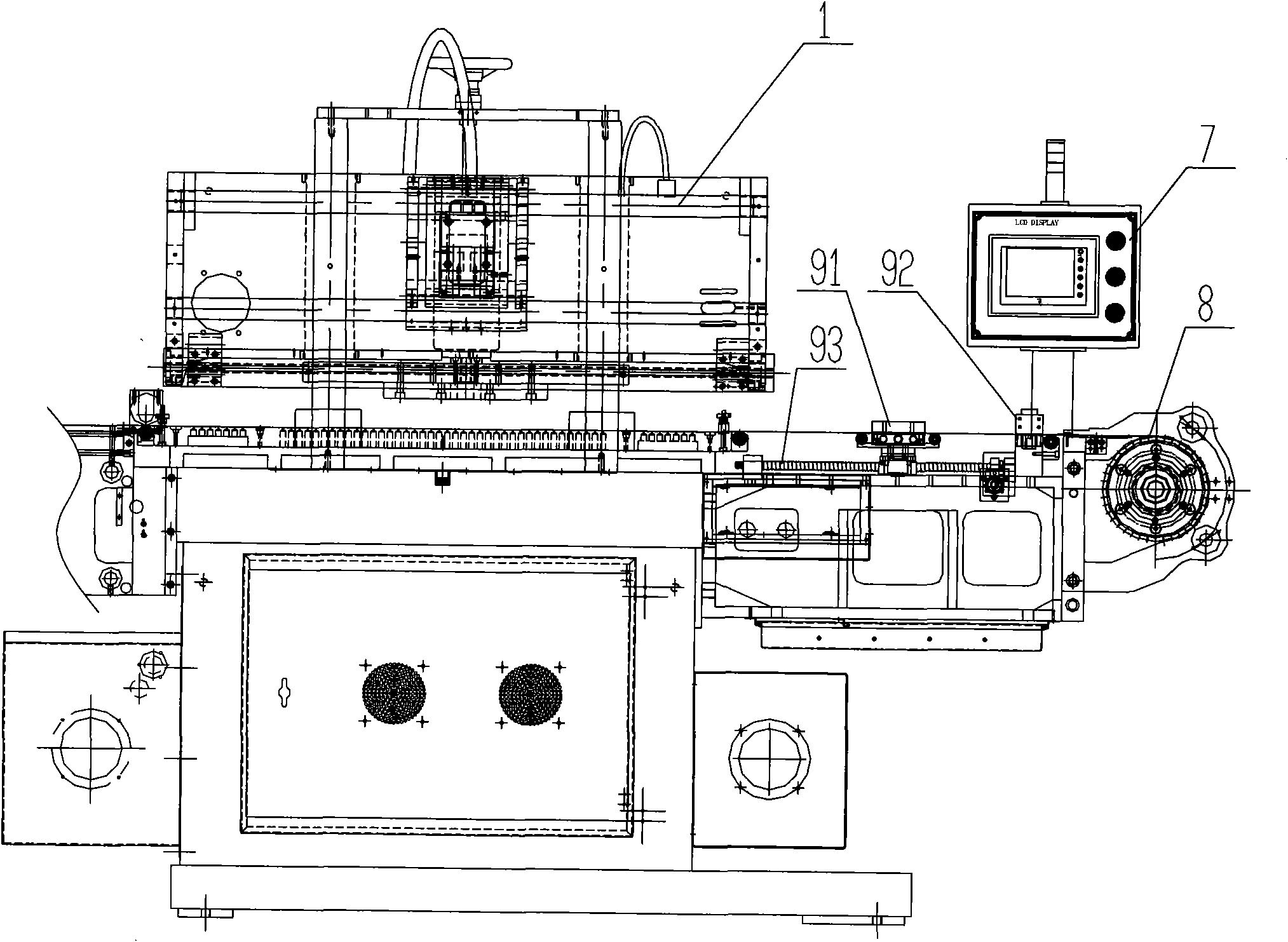

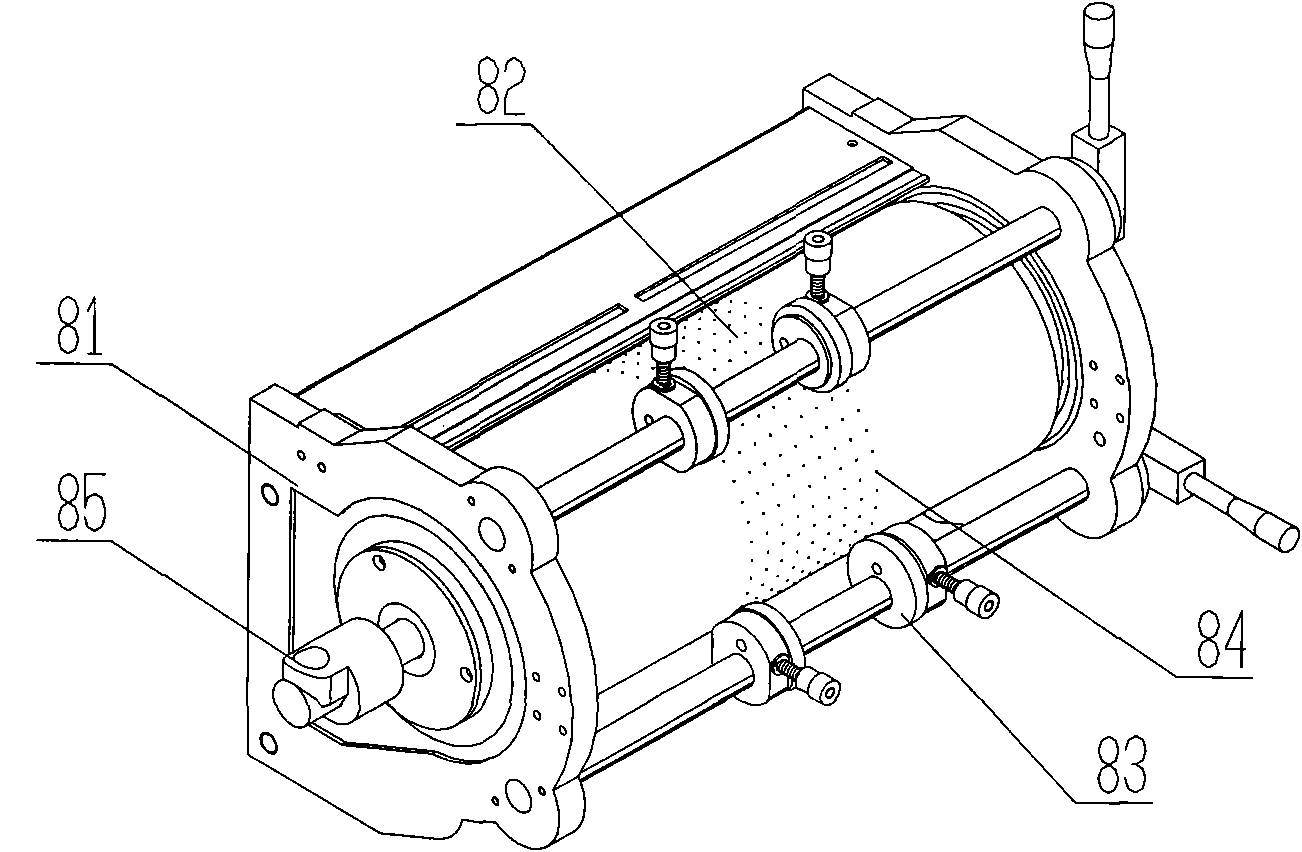

[0015] Such as figure 1 As shown, a schematic diagram of the structural composition of the automatic screen printing machine of the present invention is given, including a feeding system, a transfer device 1, a positioning punching device 9 and a pulling device 8,

[0016] A tension control system, an edge-to-edge system and a dust removal wheel are sequentially installed at the feeding end of the screen printing machine to form a feeding system. The tension control system includes a tension detector 2 and a magnetic powder clutch 3. Through the control system 7 of the whole machine, the magnetic powder The type clutch can control the feeding speed according to the feeding tension measured by the tension detector 2, so as to keep the material taut to a certain extent, thereby avoiding the occurrence of wrinkles; , during the feeding process, the whole machine control system 7 receives the displacement and offset signal of the material edge detected by the electric eye in real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com